Efficient allocation of production factors, improve production delivery capacity, reduce waste

Real-time control of production process, accurate traceability of production problems

The system reduces the communication cost, and the production unit collaborates seamlessly

Informatization runs through the whole workshop and every employee

Through the collection of production data, combined with production performance specifications, the automatic calculation of employee performance pay is realized

Task distribution and confirmation, implementation and feedback, push

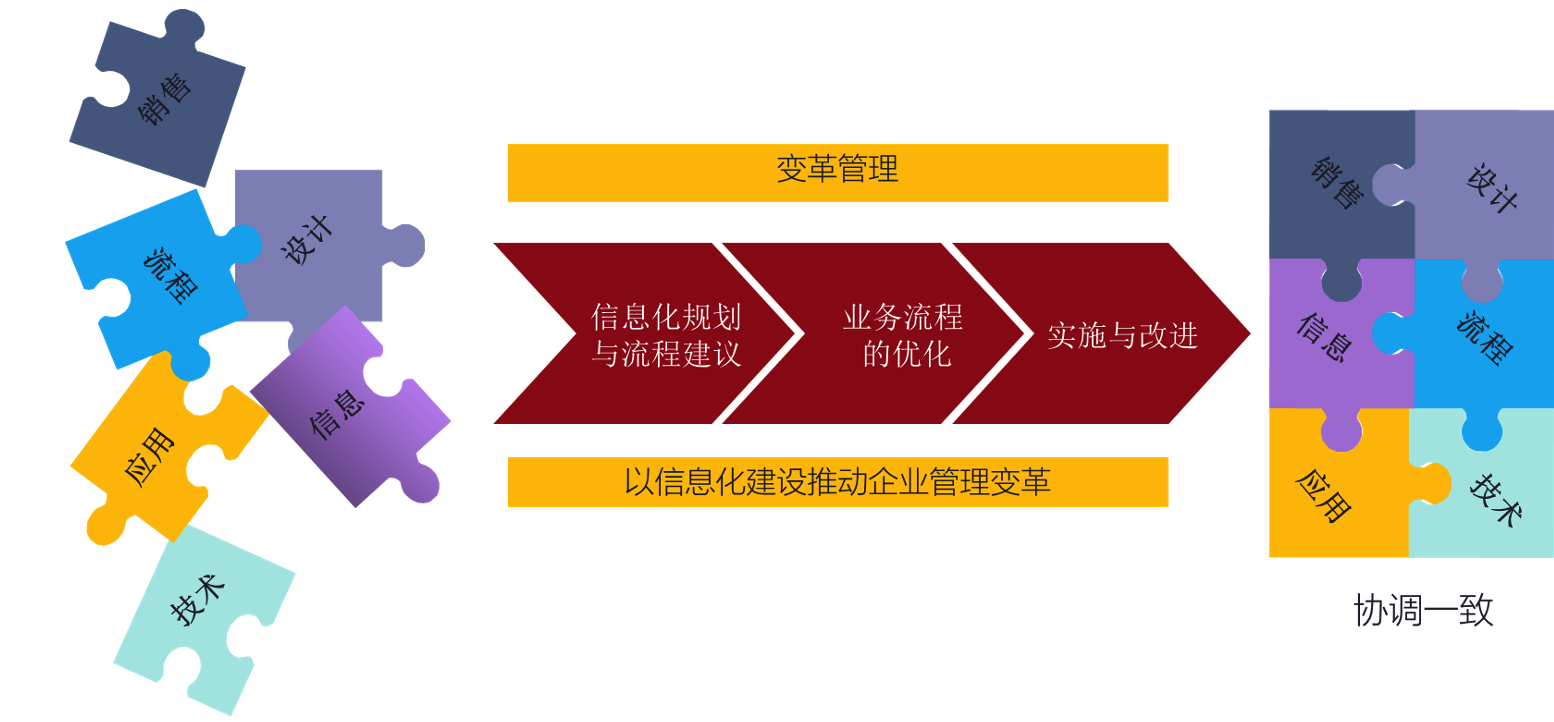

The system begins with management and finally digitizes. ZQ-MES fully considers business process reengineering optimization, operation lean thinking, and system solidification

Provide improvement support for lean production optimization through data analysis

Data acquisition technology is used to map real data of human, machine, material, method, ring and measurement

ESB bus technology is used to integrate the data of each system into the data pool to avoid data island

Use data analysis models and algorithms to make management decisions more accurate

Standardize production, processing and other equipment management

Improve equipment production efficiency, reduce equipment investment

Strengthen employee performance appraisal and improve the efficiency of quick response and handling of exceptions

Improve key operations automation management, reduce the input of manpower and material resources