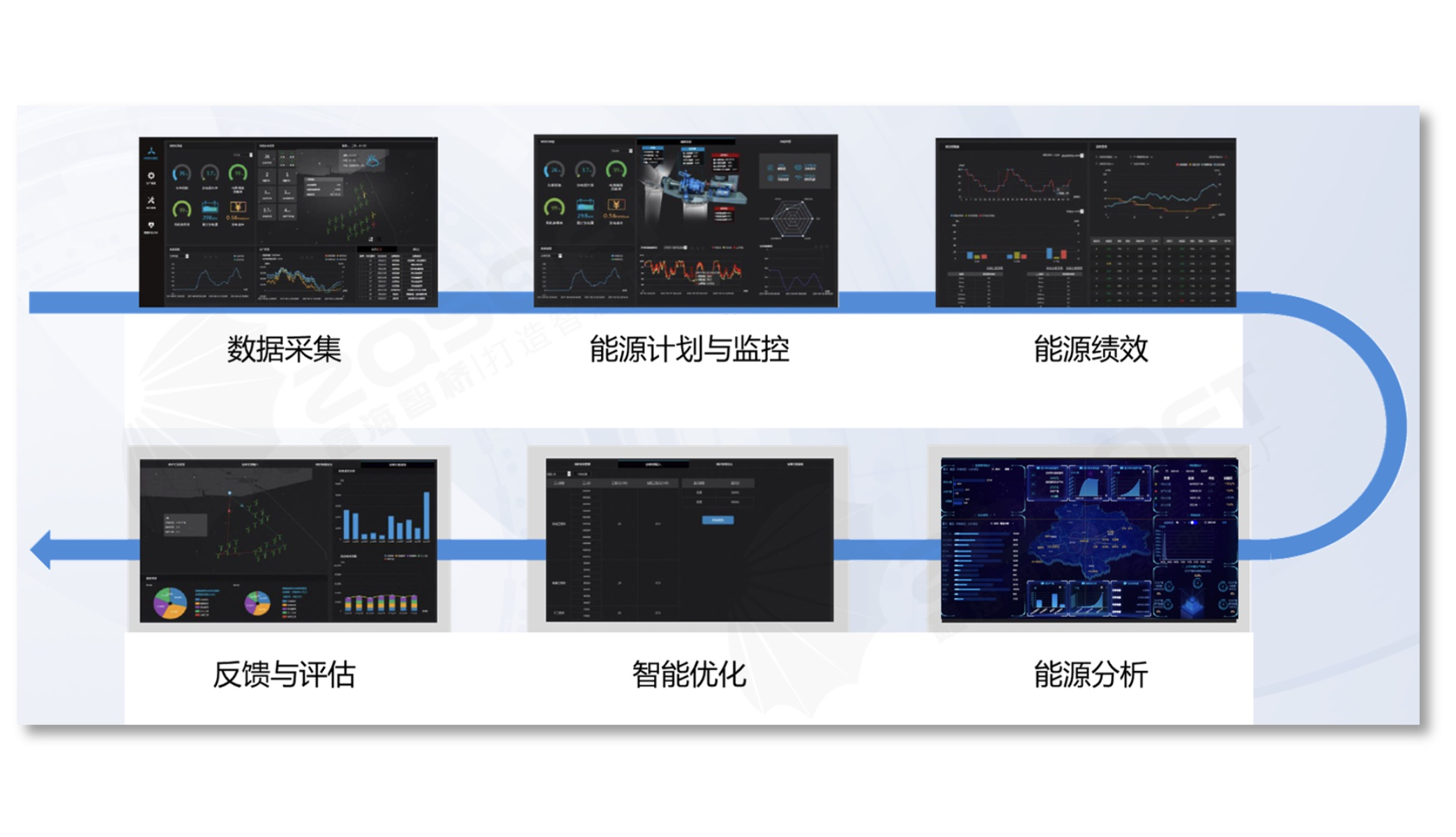

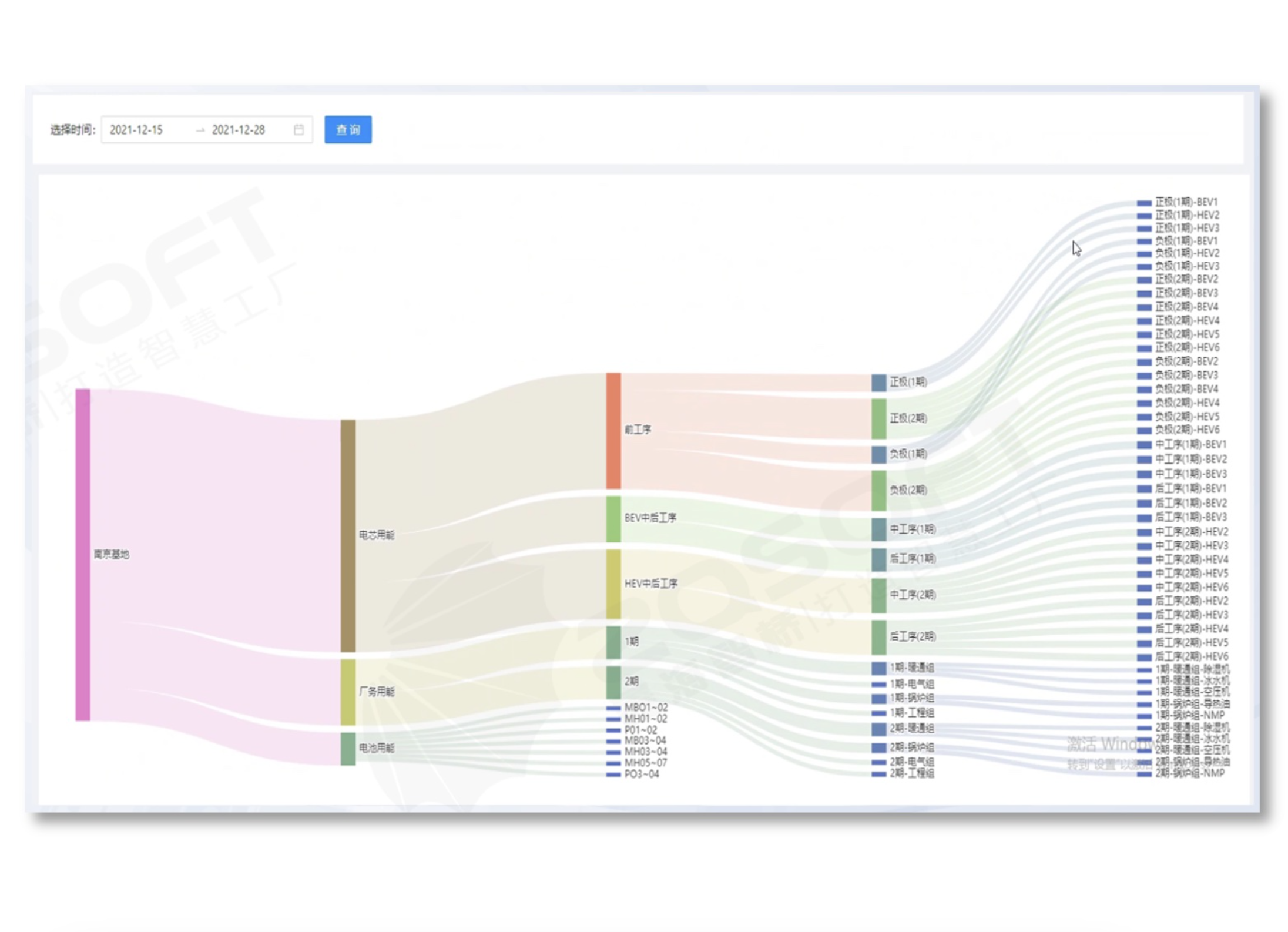

Multiple energy consumption meters are uniformly connected.

Implement centralized collection and management of energy consuming devices.

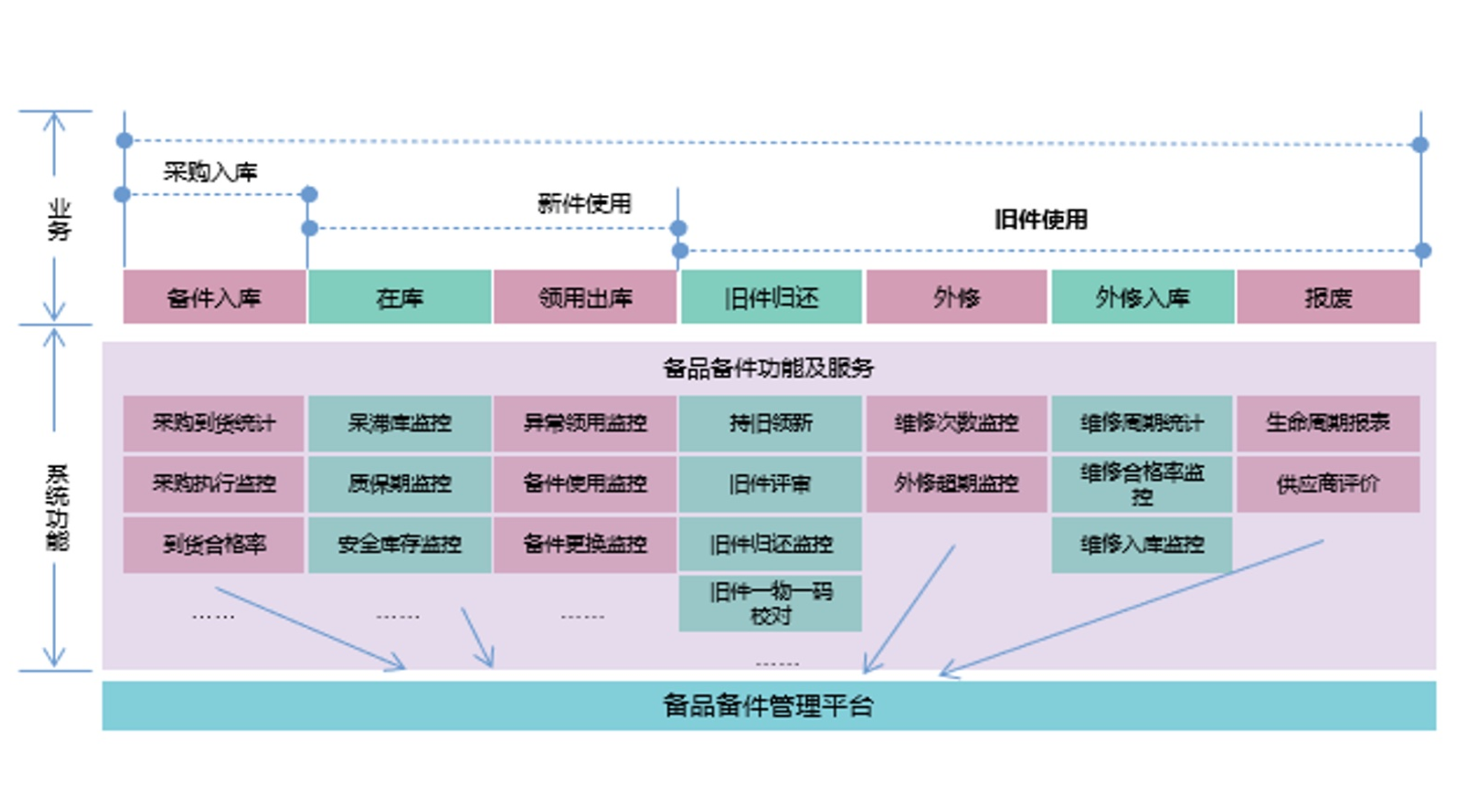

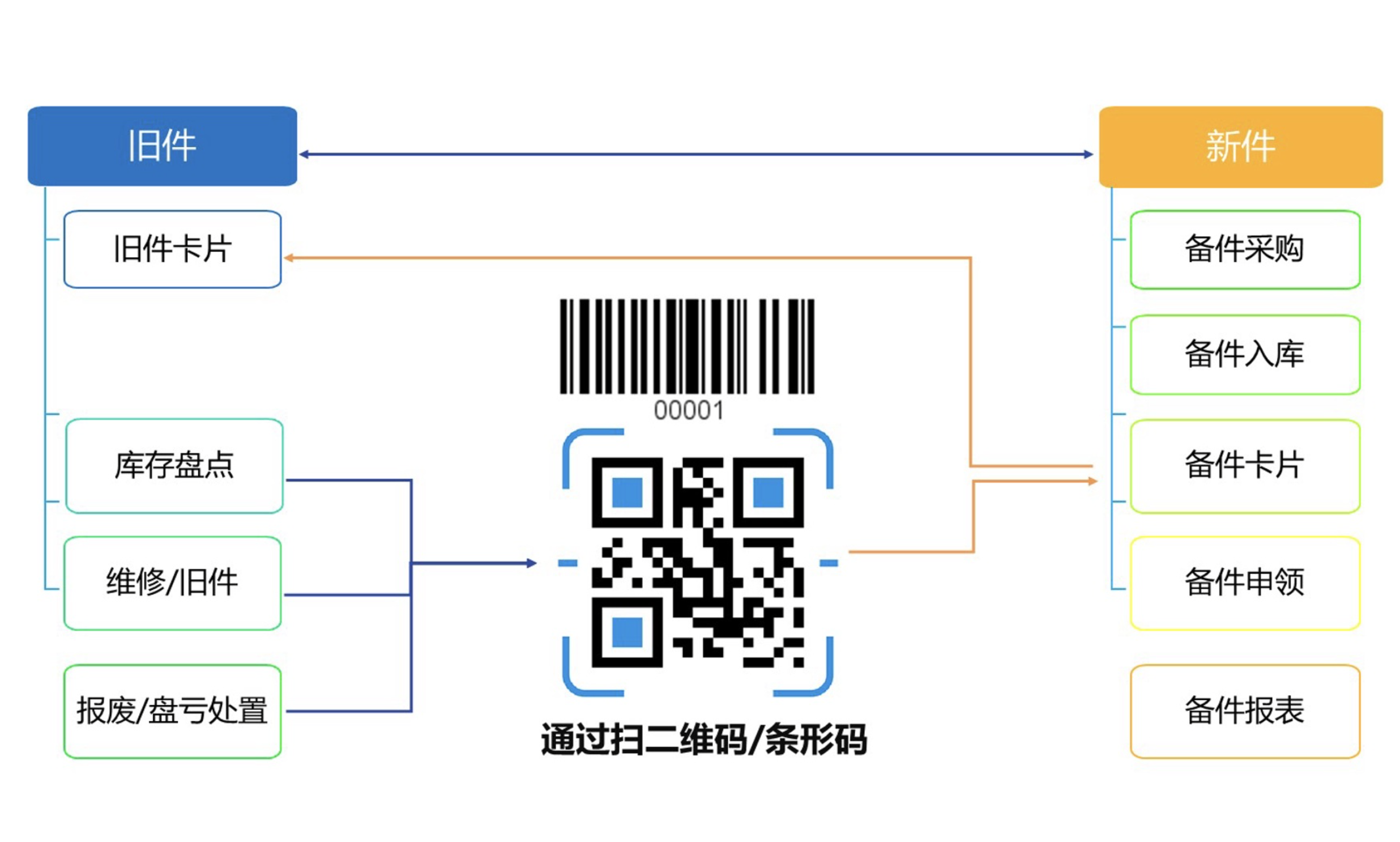

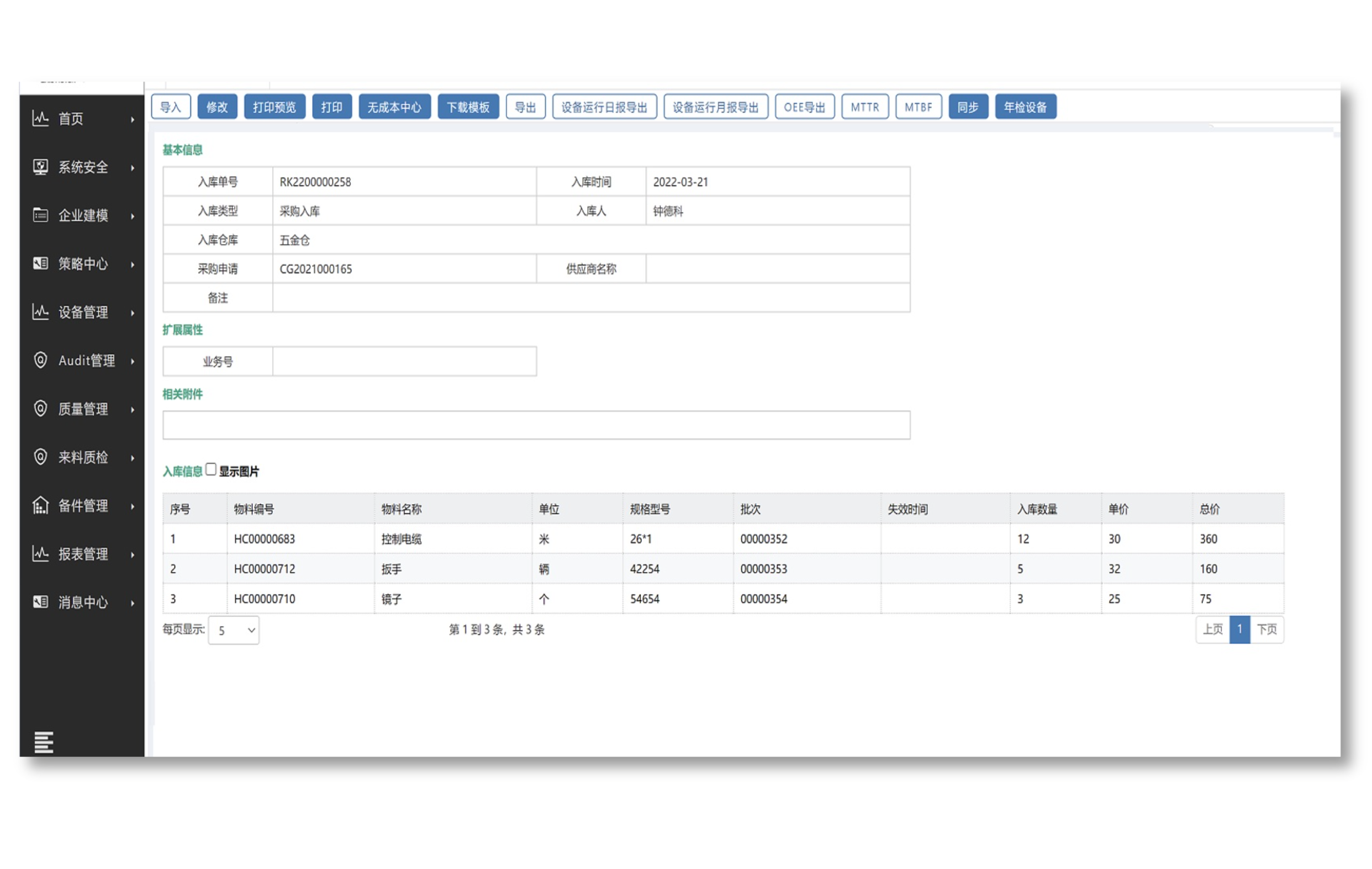

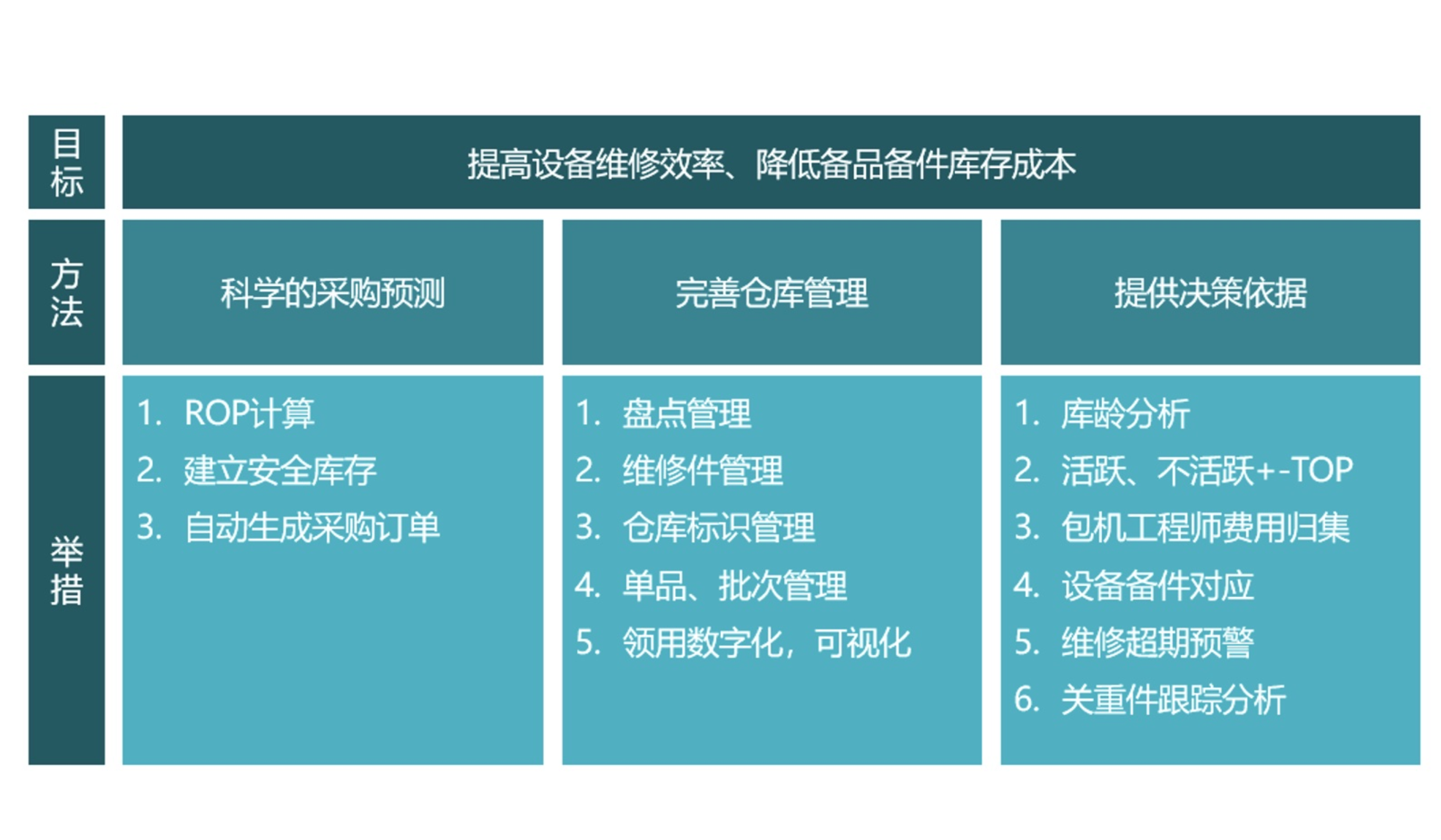

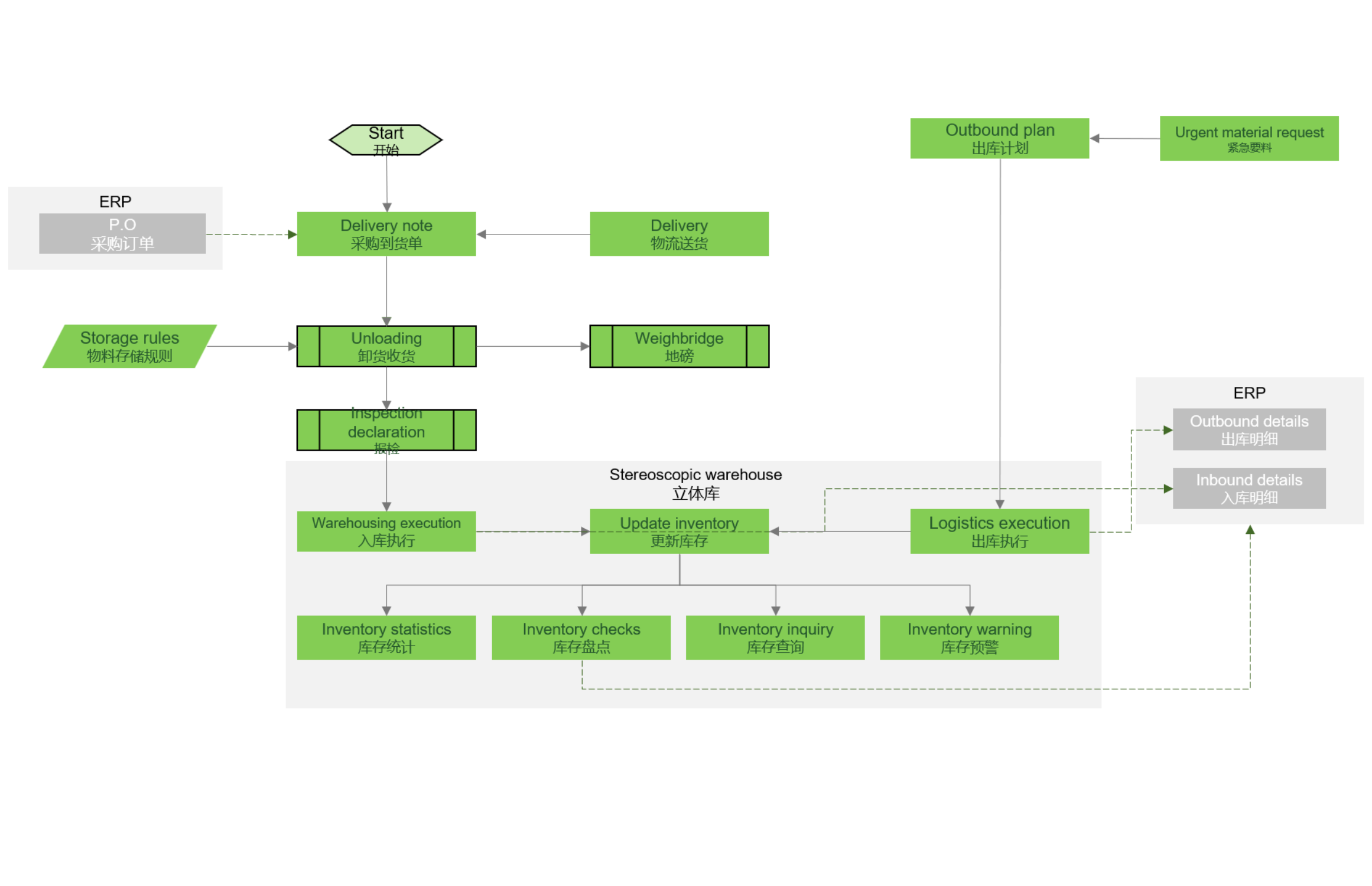

Through information technology, automated management of spare parts storage, outbound, inventory inquiry, inventory counting and loss, warning and reminder functions can be achieved.

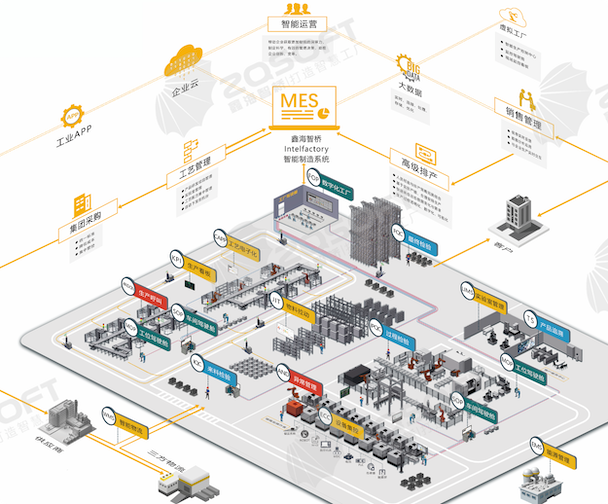

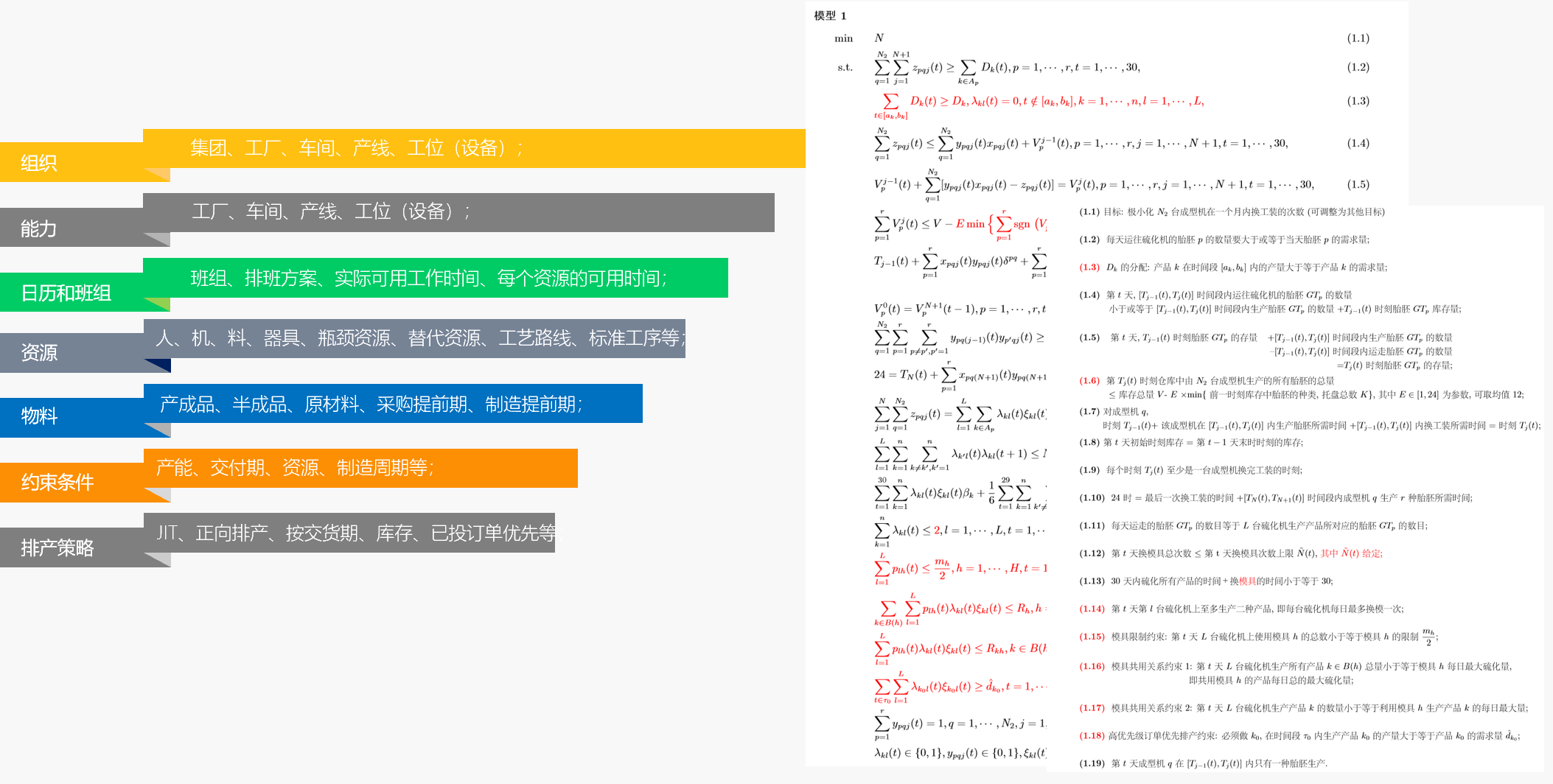

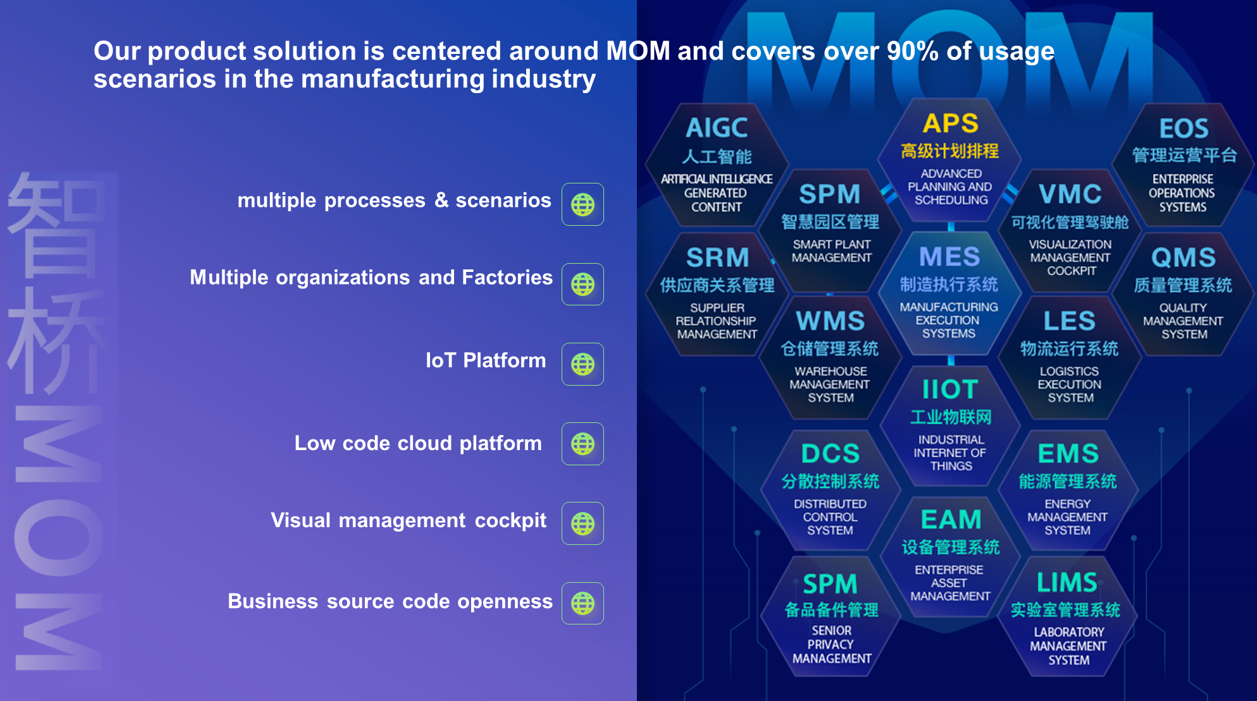

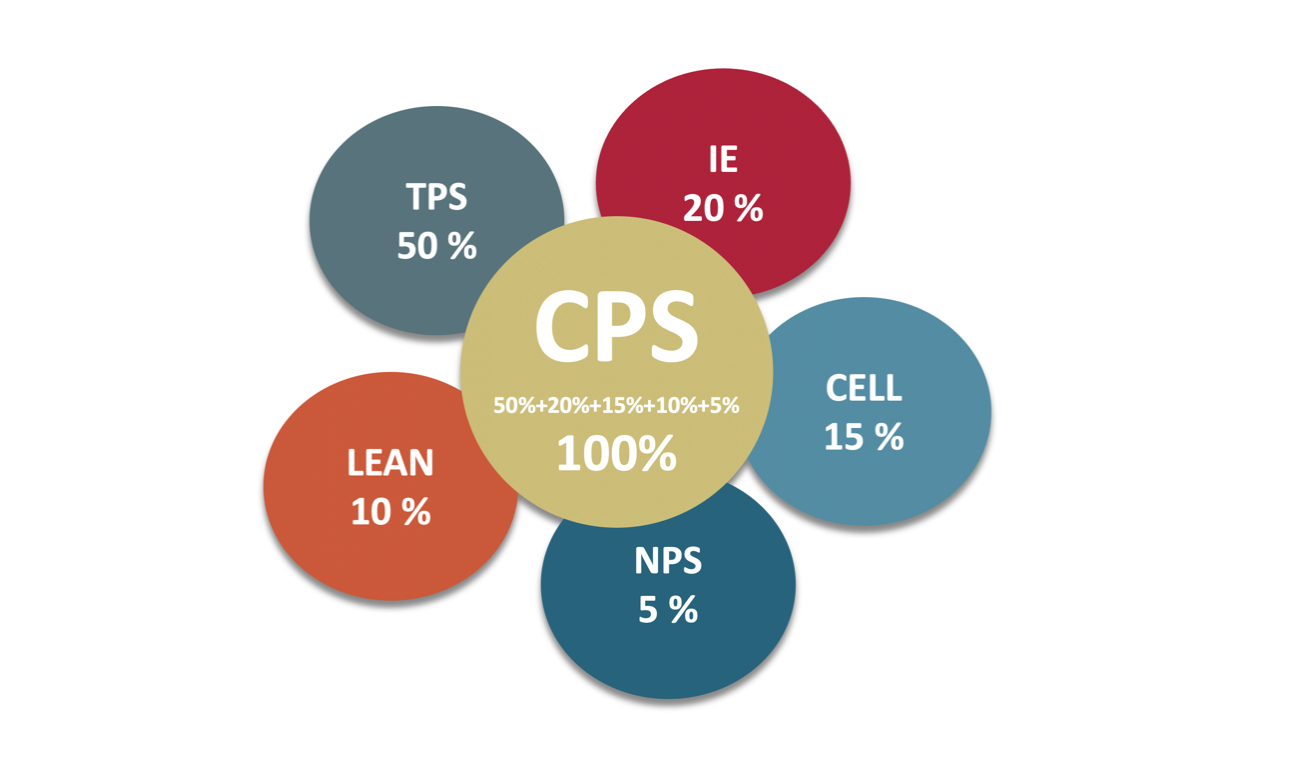

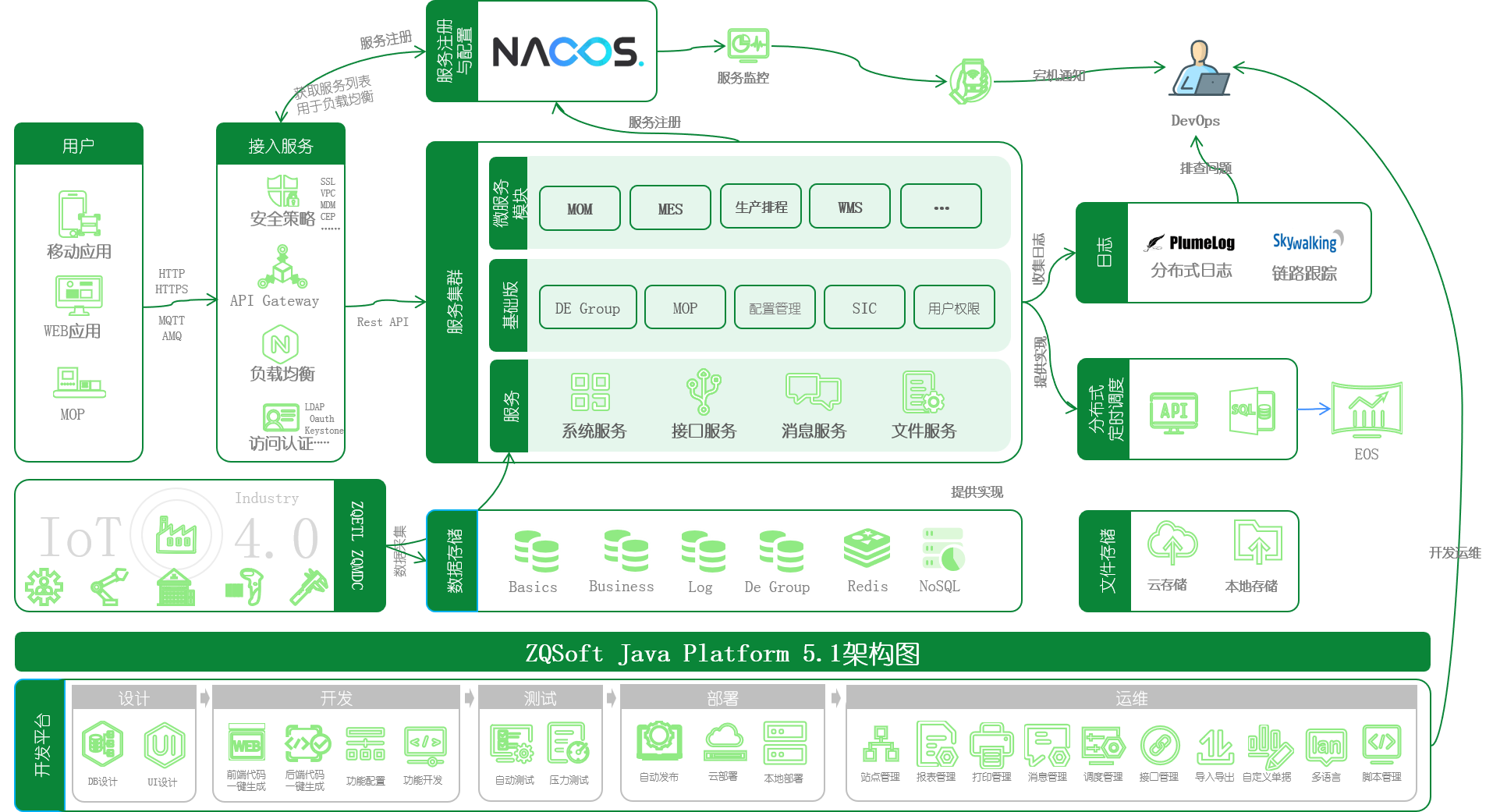

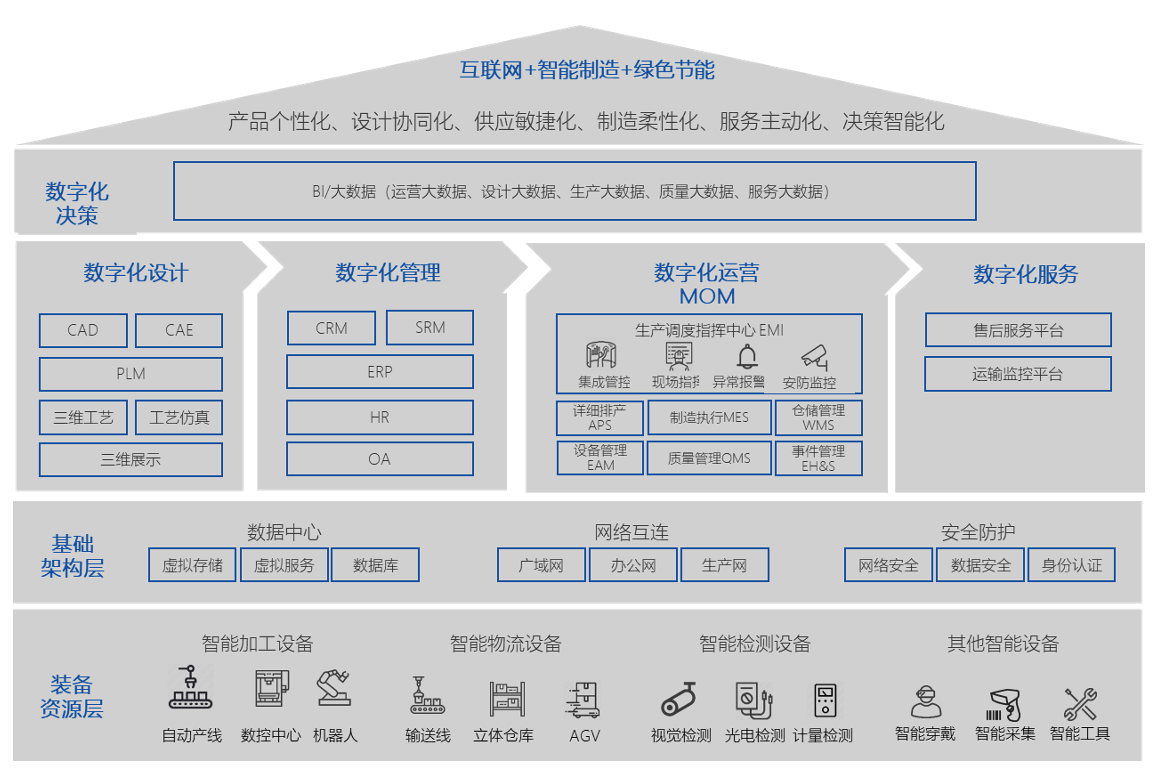

In the field of intelligent manufacturing, solutions need to be optimized and designed according to industry characteristics to adapt to the complex needs of specific fields.

Fragmented scenarios require cross process stages and system integration to achieve full process data coverage and unified management.

Flexibility is key, and solutions need to quickly respond to industry changes, meet diverse customer needs and market adjustments.

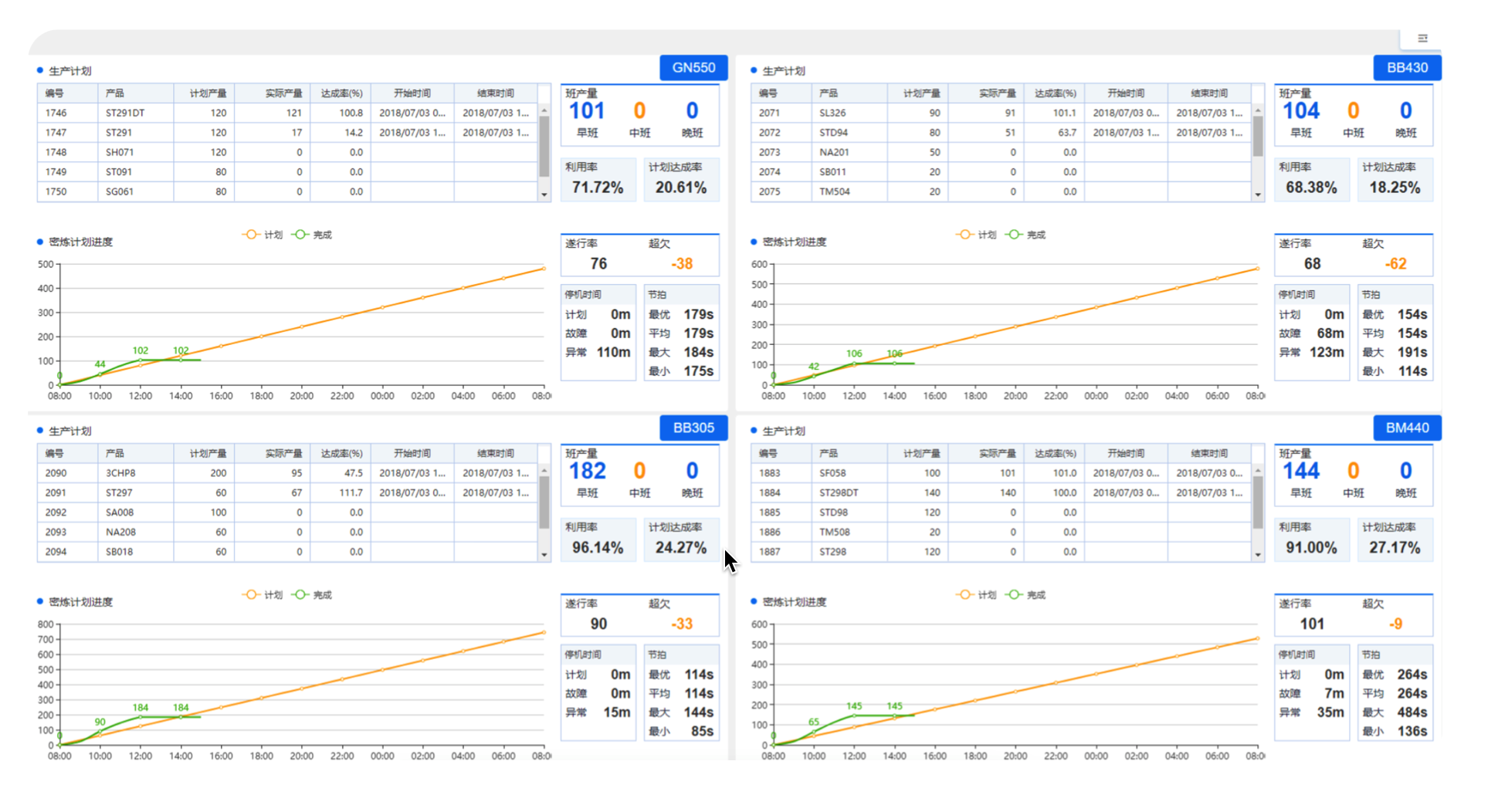

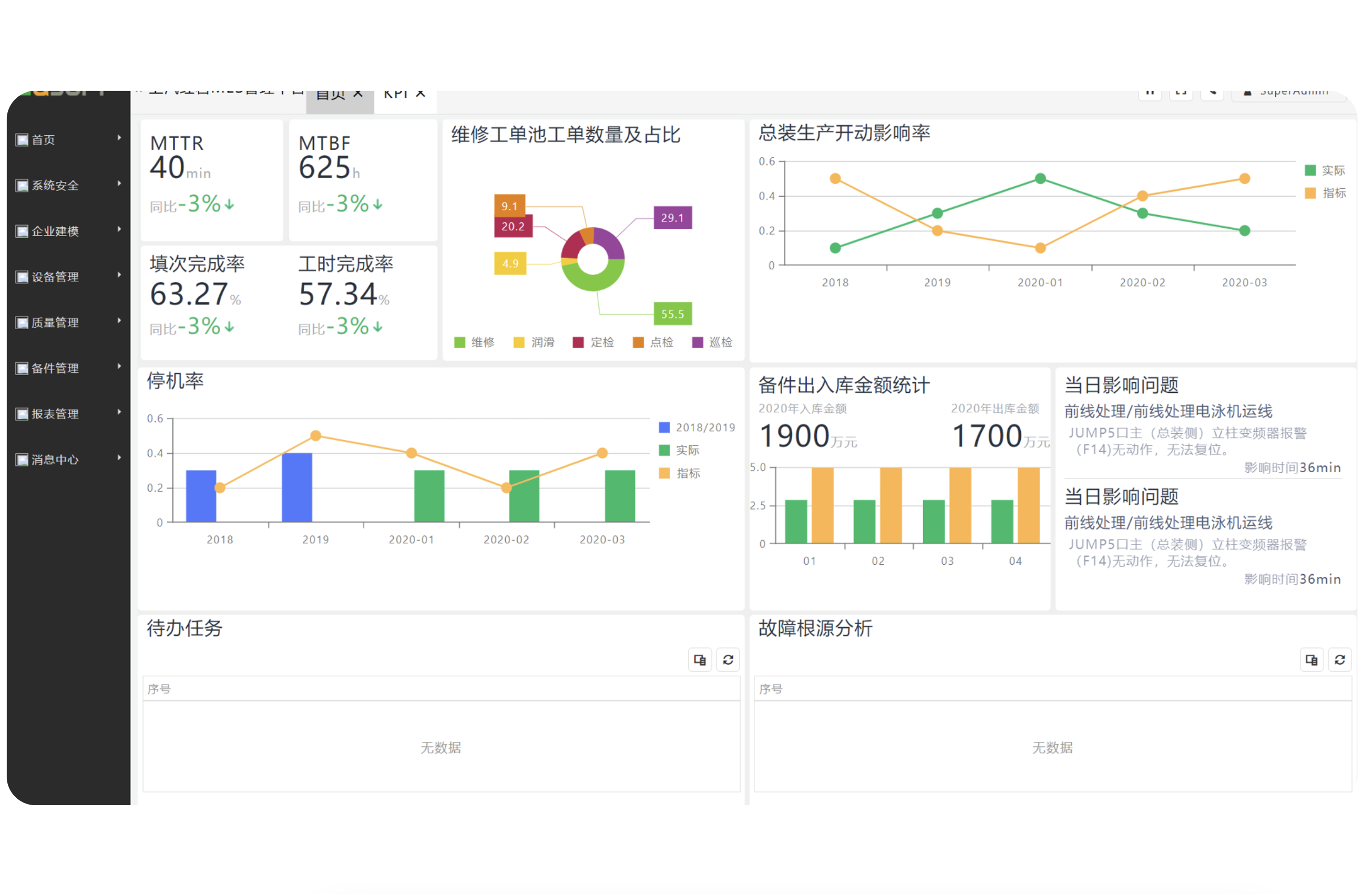

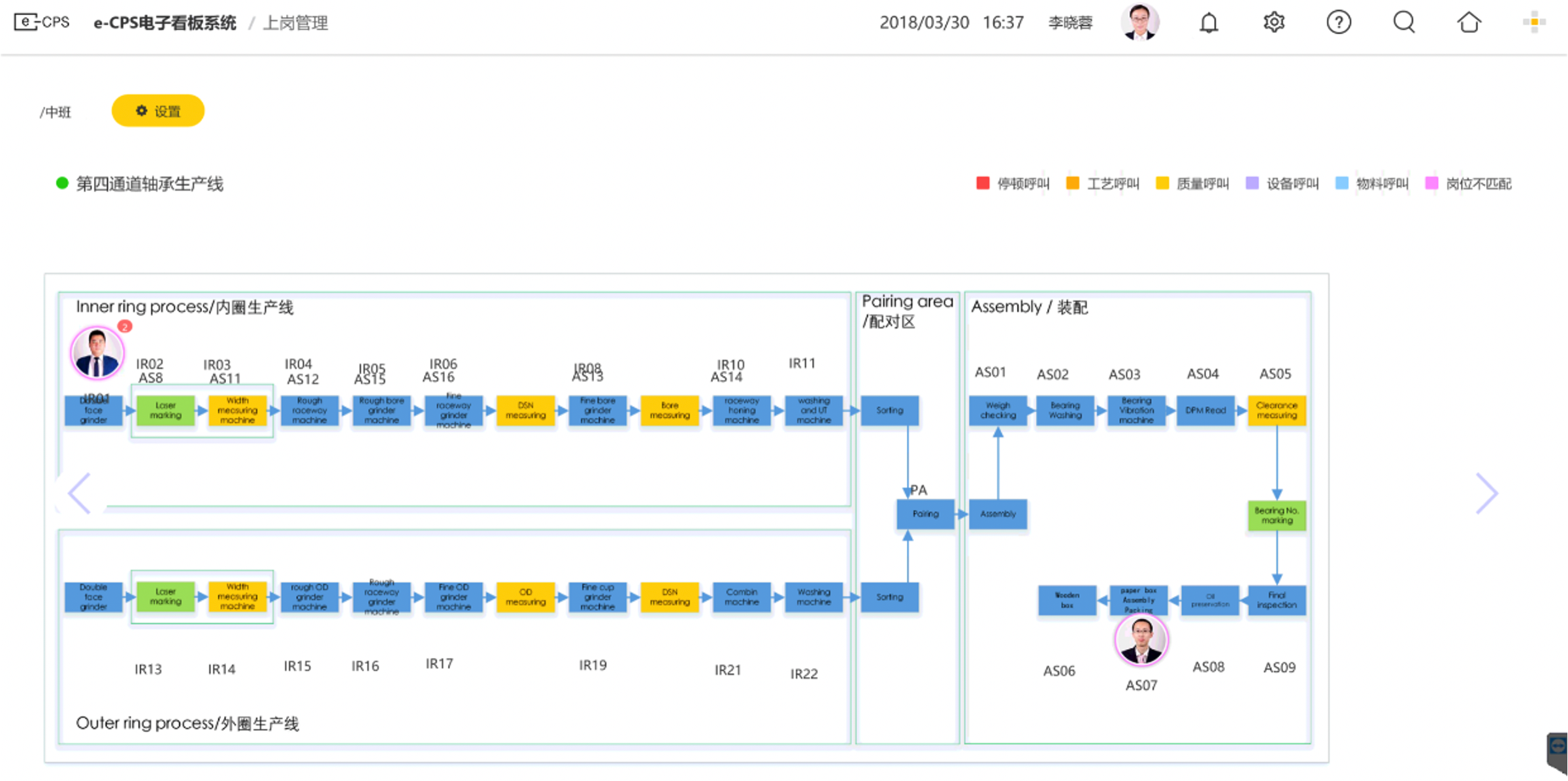

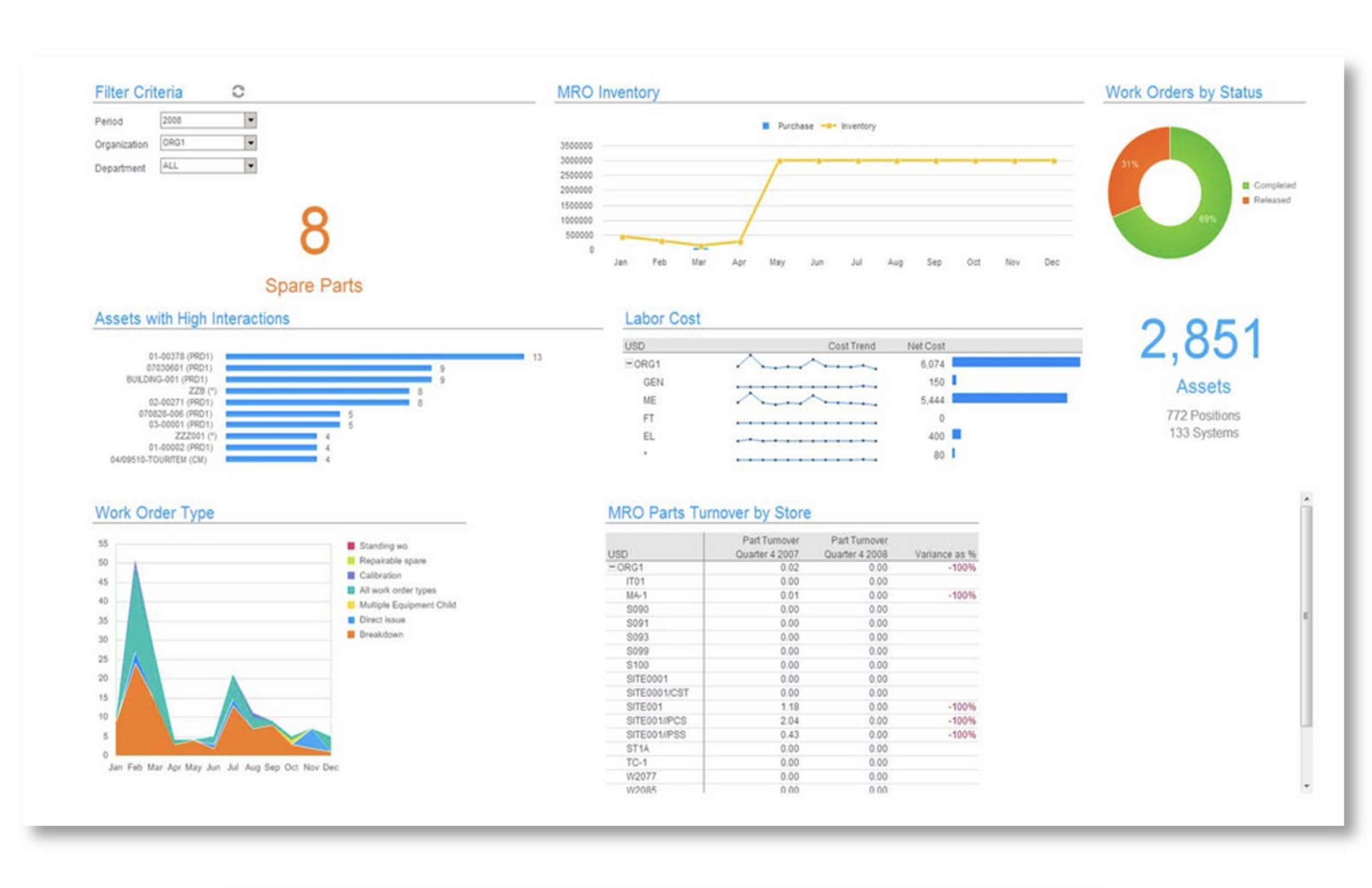

Global control of Kanban KPIs.

KPI can be viewed for different roles through tile and drag configuration.

Graphical data allows you to have a clear and visible view of the warehouse.

Informationization runs through the entire workshop and every employee.

By collecting production data and combining it with production performance specifications, automatic calculation of employee performance-based wages can be achieved.

Task assignment and confirmation, execution and feedback, achievement push.

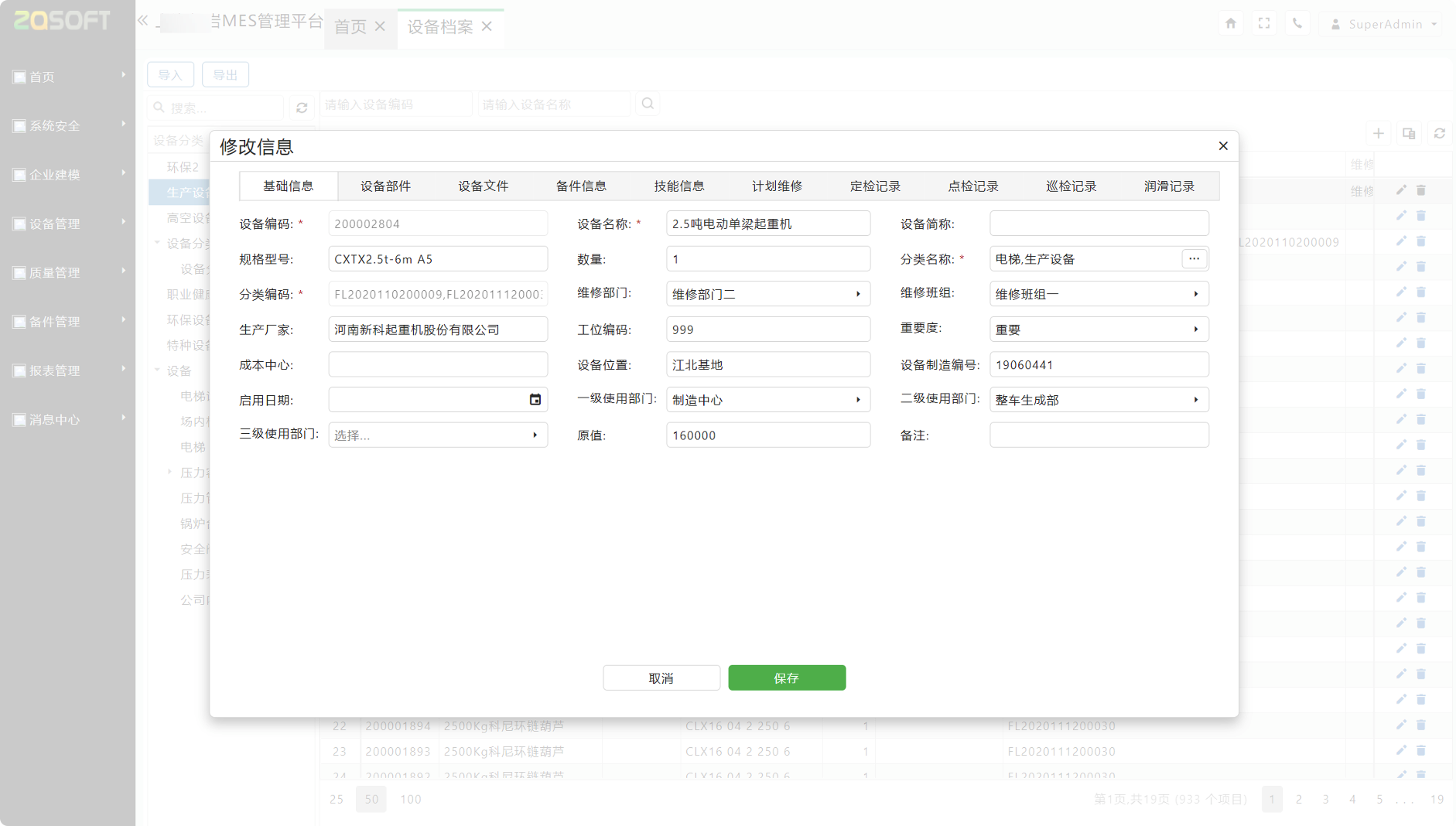

Help create a complete device asset structure tree, with one click access to basic information, BOM structure, operation and maintenance records, spare parts usage, equipment files, operation logs, and more.

Structured and standardized management of spare parts and document information, information configuration engine technology, easy to use, operation configuration, and clear application.

The system management dimension is more diversified, focusing not only on production indicators, but also on operational indicators, so as to truly reduce costs and increase efficiency

The production unit is no longer isolated, using the independent and controllable ZQ-MOM core platform, comprehensive business collaboration, no longer split the business chain

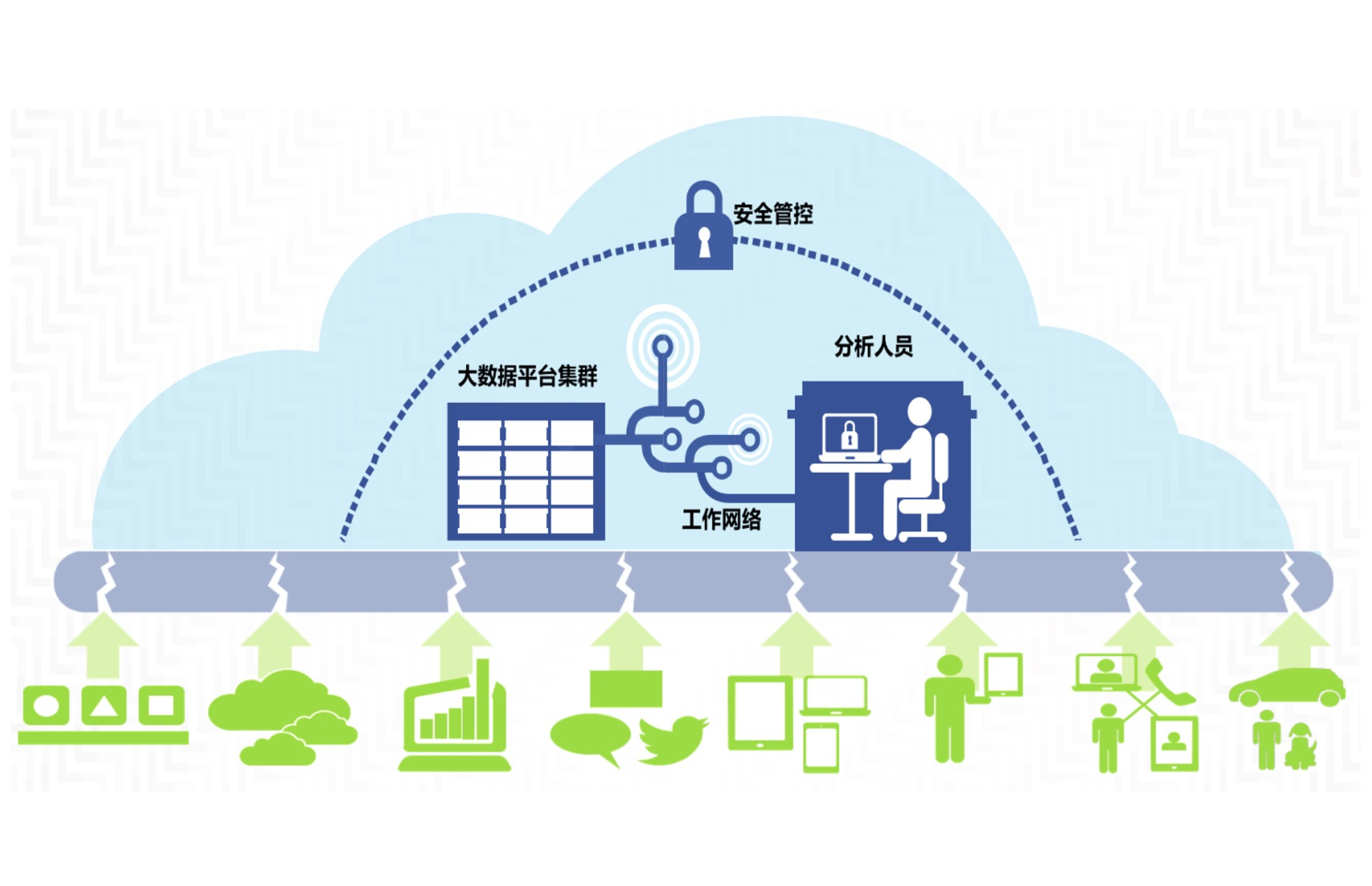

Driven by industrial big data, change the operation mode of factories

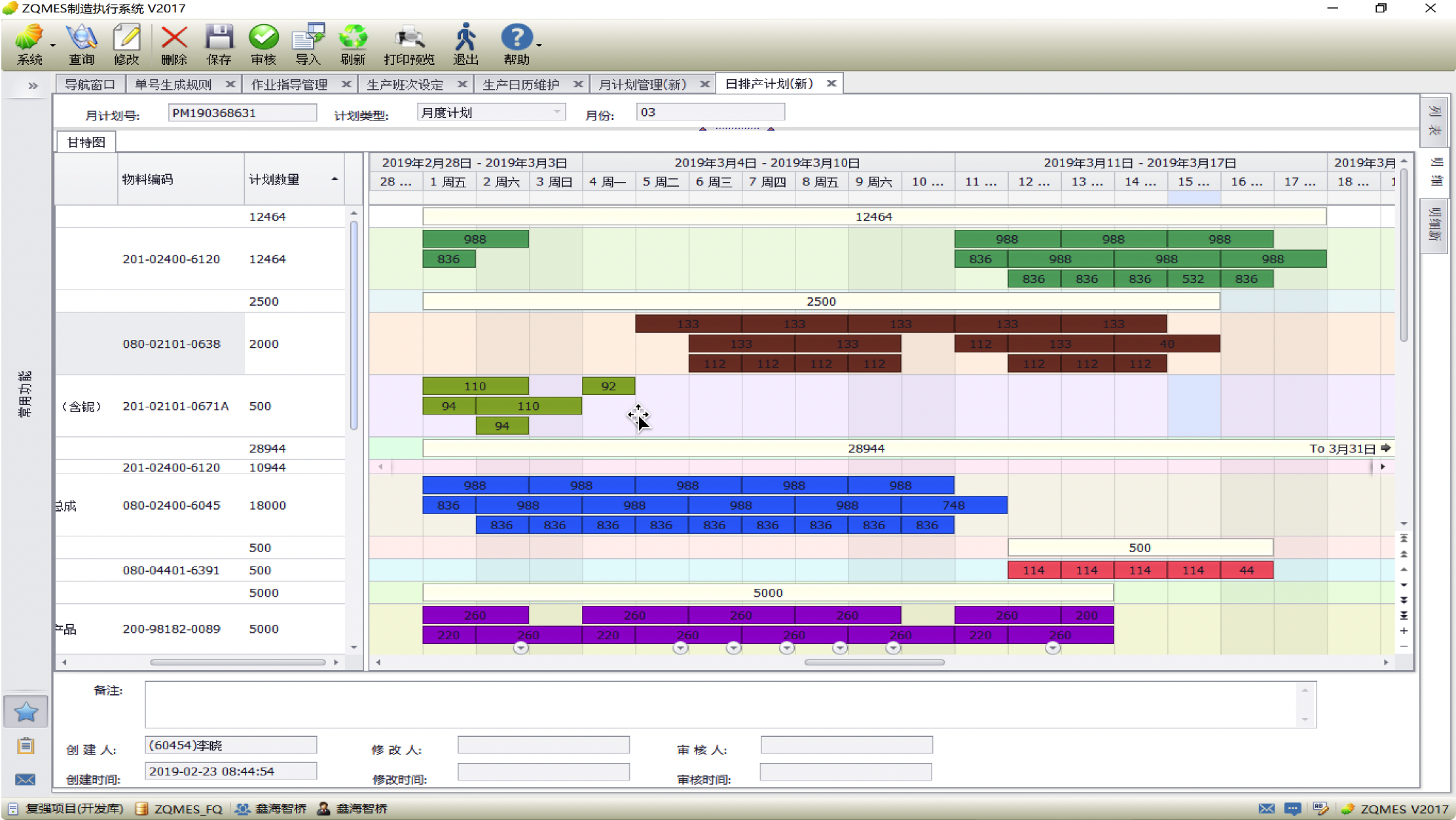

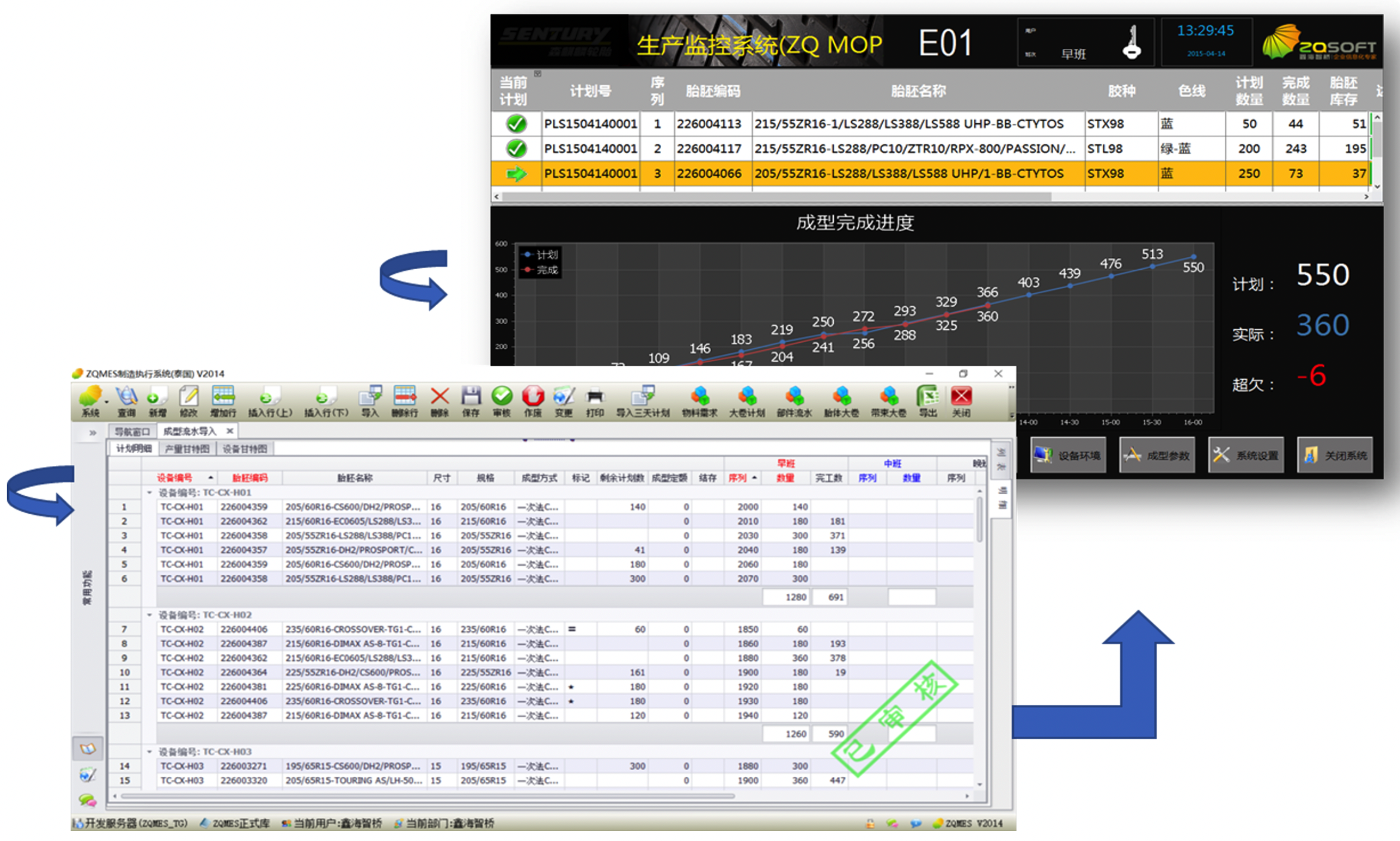

Based on the self-developed production scheduling logic model, it can deal with the production of different types of orders

Algorithm engine, precise constraints, and manual experience make the scheduling executable and operable

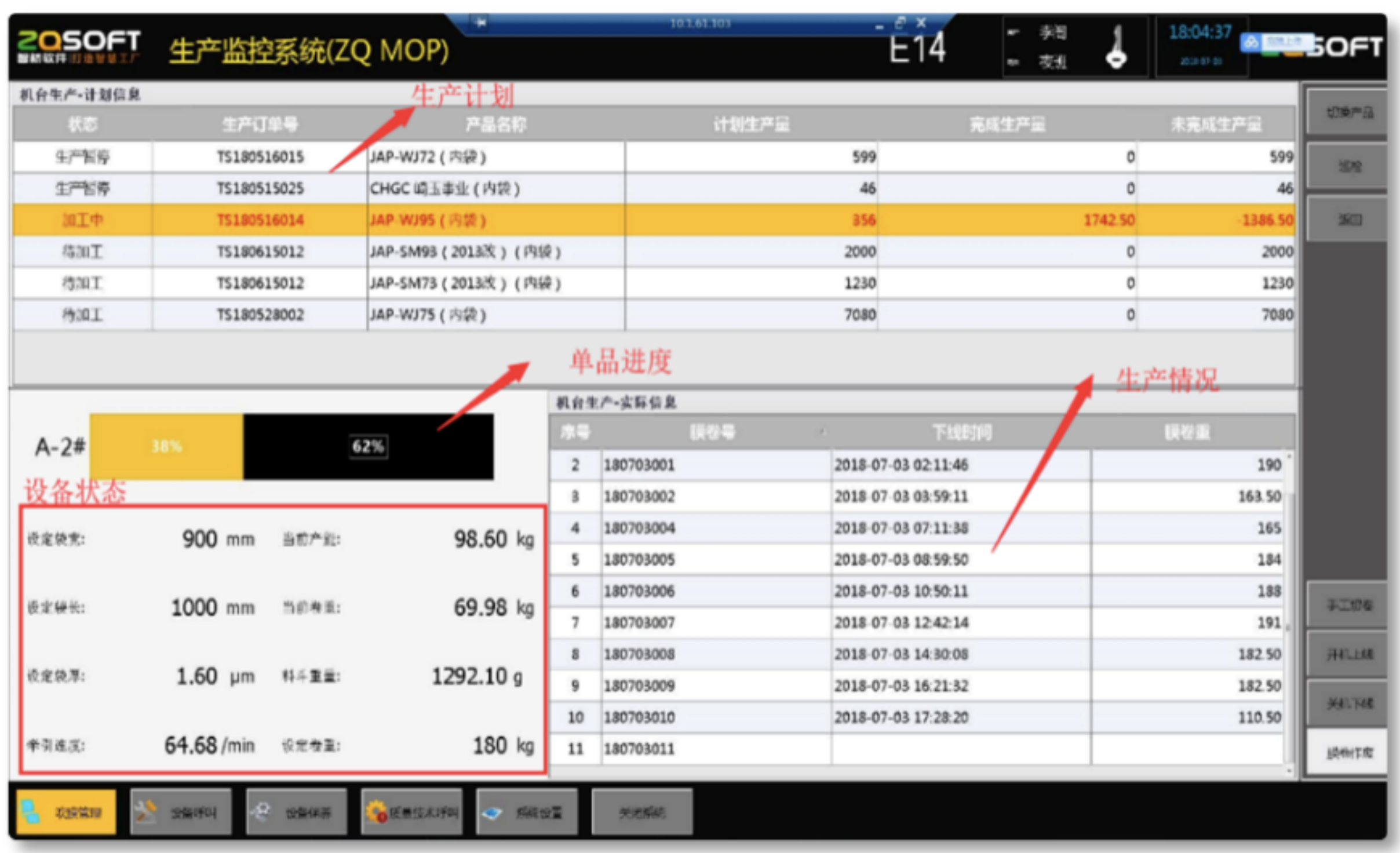

EOS electronic whiteboard to realize production data monitoring and task kanban board of production workshop team

Shift records, team meetings, safety training and other business needs

Help the team leader to implement the point to point assignment and task tracking

History tracing of safety, production downtime, defect analysis, etc

Front-end (executor)

With light weight, convenient and efficient as the core, mobile phone and PDA are recommended

Message (delivery side)

The use of TV, LED, to ensure the logistics pull information transfer efficiency

Backend (analytics)

Using PC, conference tablet, etc., to achieve data query and analysis

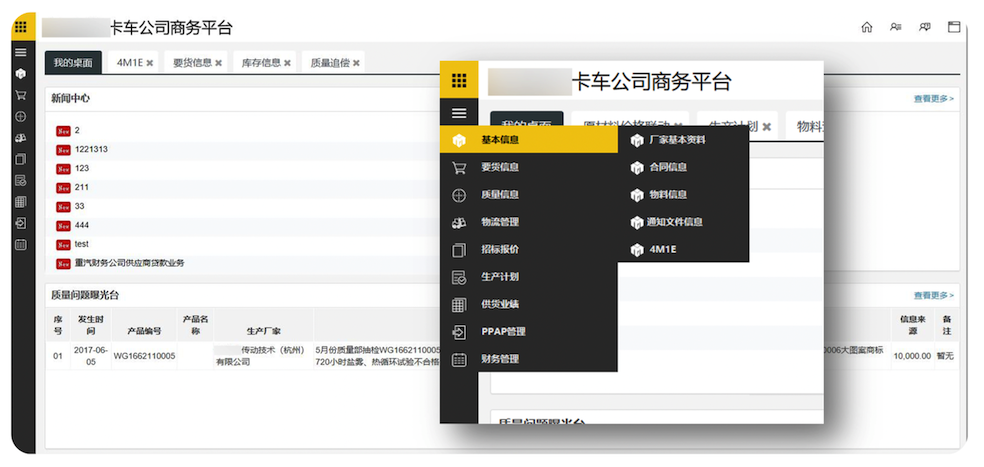

Partners are managed uniformly in the system to realize the control of procurement quota and procurement limit

Through ZQ-SRM system, complete the coordination of production plan, material requirement, purchase price, purchase document and drawing

Purchase invoice reconciliation function, so that partners and procurement staff are not "upset"

Paperless office, improve the efficiency of information transmission

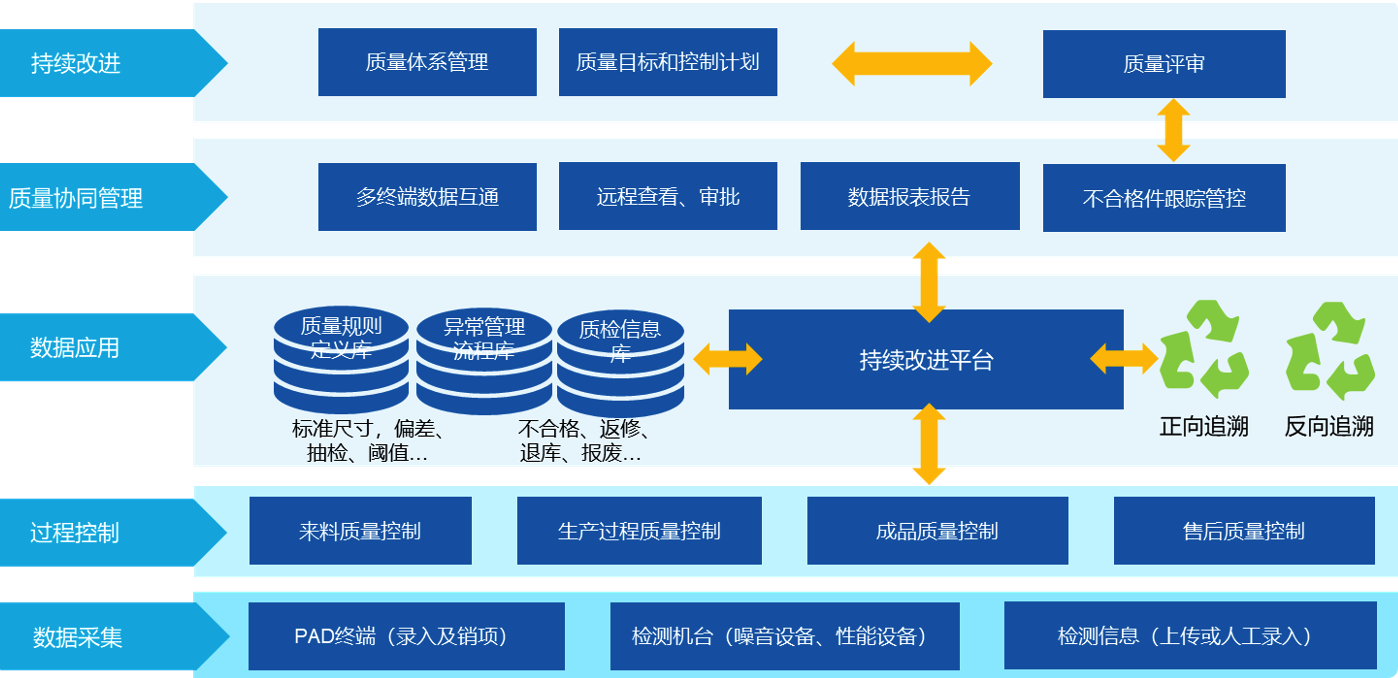

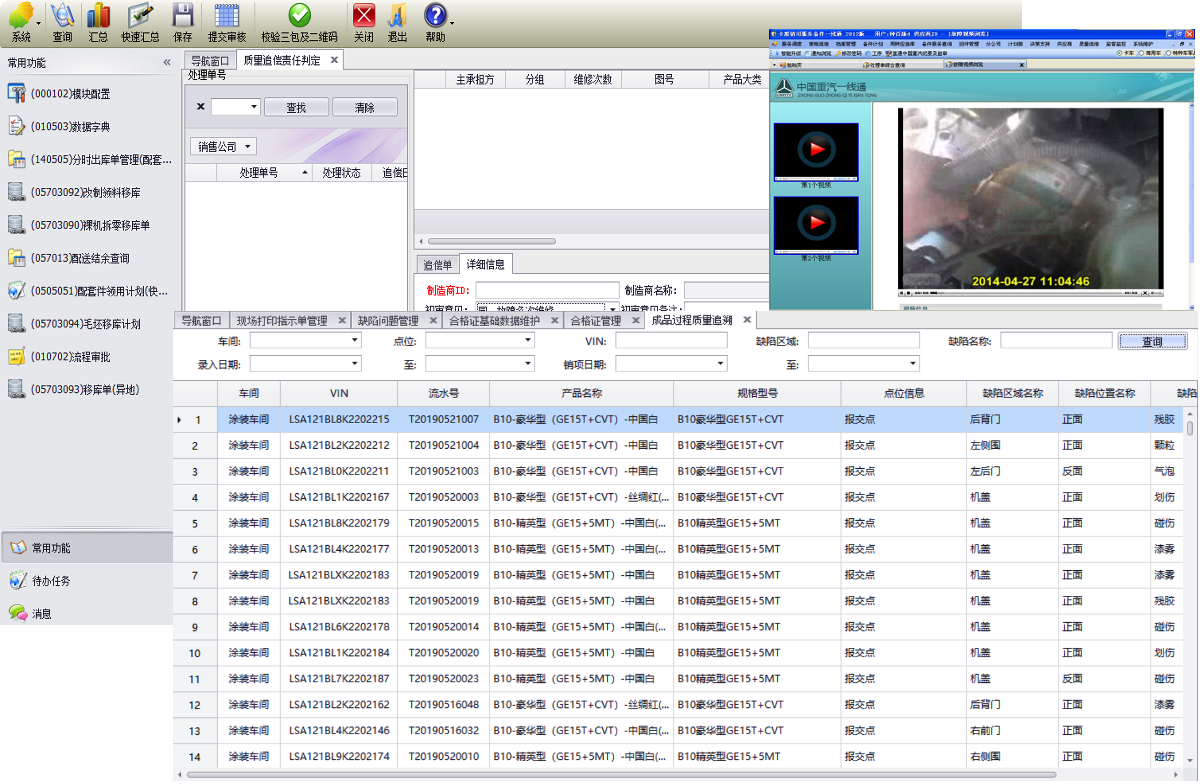

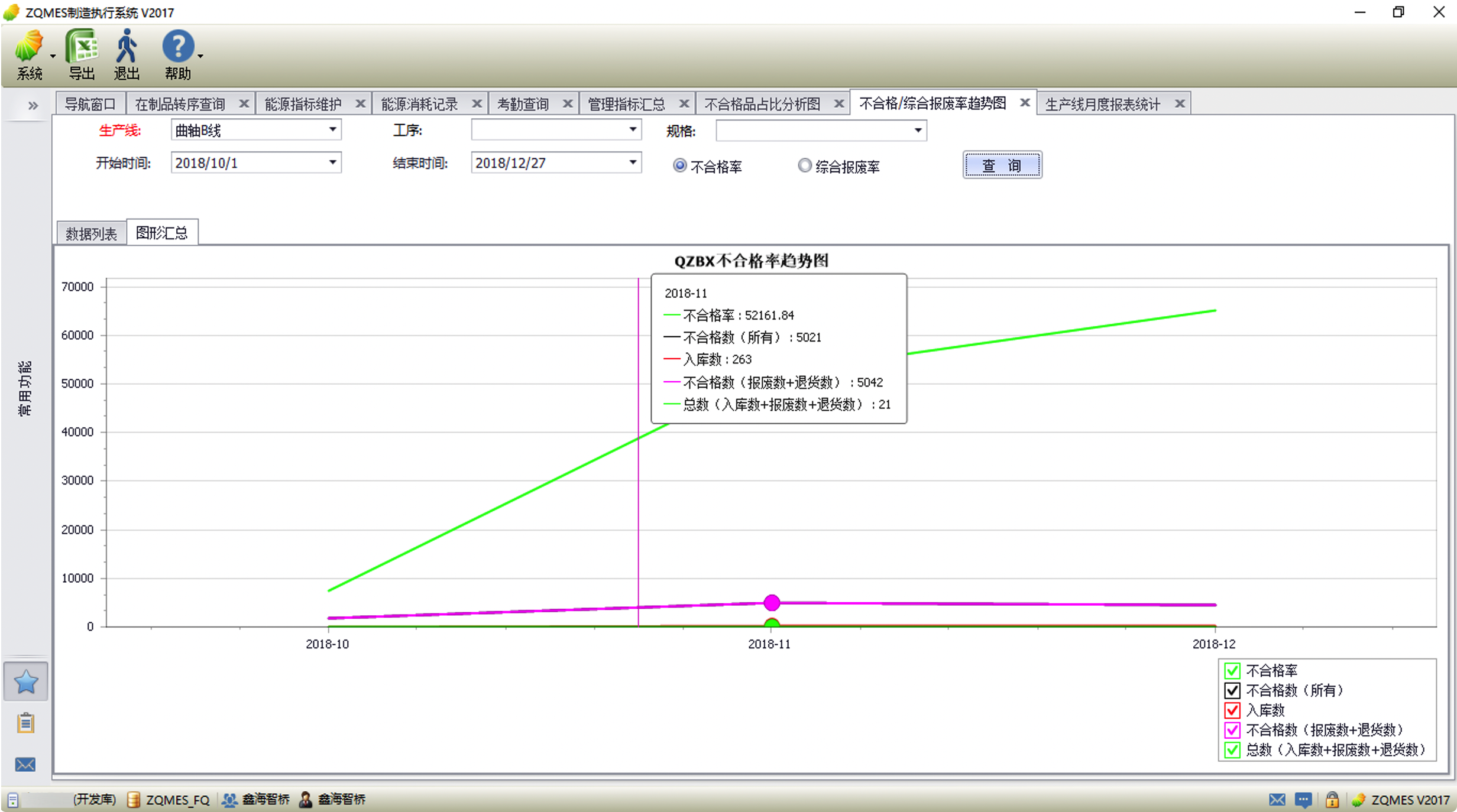

The whole process, standardized quality control, let the quality management become simple

A variety of convenient data collection methods, manual + networking, improve efficiency and accuracy

Quality problem warning upgrade system

Scheduled reception

Check and monitor production progress

Work instruction and drawing management

Report of completion

Quality self-test

Production Inquiry

Abnormal call

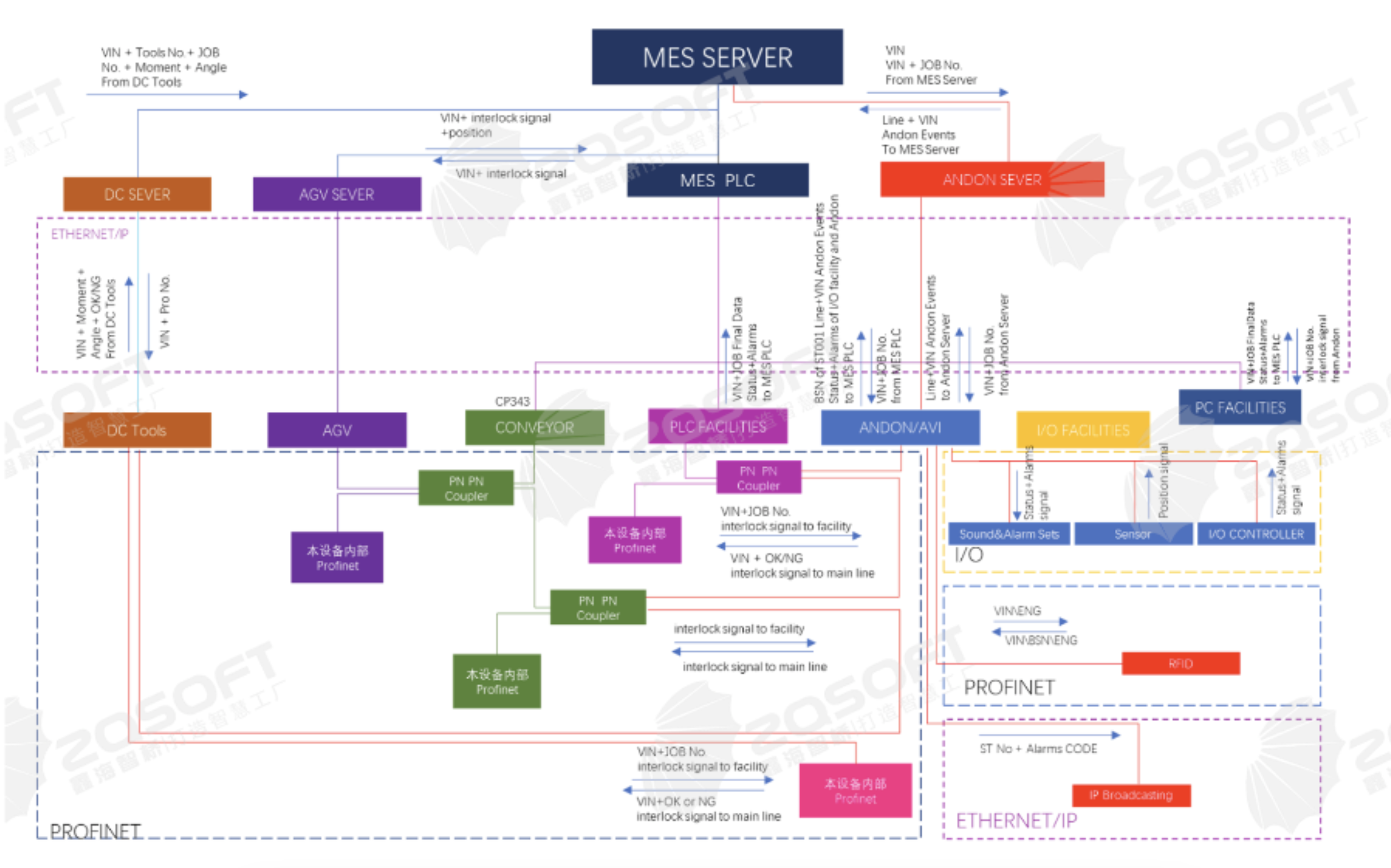

Adapt to mainstream communication protocols, operating systems PLC。

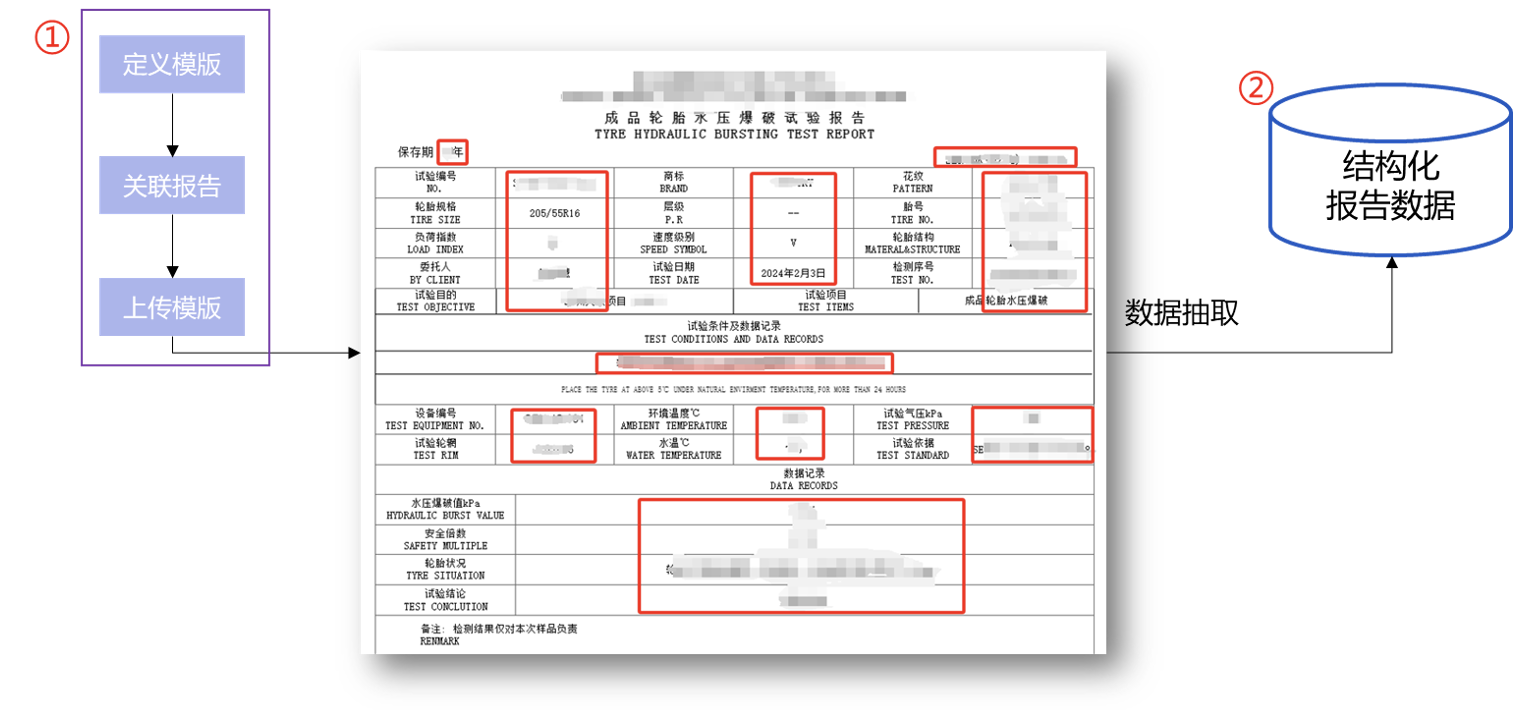

Support data recognition for multi format text.

Integrate edge computing technology to achieve rapid data response.

Professional data management mechanism to provide data security assurance.

"Extract" :

Getting data out of the various raw business systems is a prerequisite for all work

"Conversion" :

According to the pre-designed rules, the extracted data is transformed to unify the originally heterogeneous data format

"Mount" :

The transformed data is imported into the data warehouse incrementally or completely as planned

Diversified interfaces and convenient access to third-party systems.

Breaking down information silos.

Using QR code technology to achieve fast input and quick query of spare parts information.

For spare parts that require tracking and analysis, configure a one item one code system in SPM.

By using various methods such as handheld terminals and scanning guns for reading, the efficiency of spare parts identification and management can be easily improved.

The intelligent decision-making system effectively ensures balanced and continuous operation of production tasks, optimizes resource allocation, and ensures efficient execution of production plans.

The decision-making system supports enterprises to quickly respond to changes, meet high-frequency judgment and decision-making needs, and help achieve precise production management.

By automating repetitive tasks, reducing human intervention, improving work efficiency, reducing the risk of operational errors, and optimizing enterprise operation processes.

Efficient allocation of production factors, improve production delivery capacity, reduce waste

Real-time control of production process, accurate traceability of production problems

The system reduces the communication cost, and the production unit collaborates seamlessly

Microservice framework, loosely coupled business links, and efficient expansion of front-end business

With a powerful system platform, system development, implementation, API services

Solid back-end cloud infrastructure; IoT suite and edge computing layer

Plan-on-site linkage technology to ensure accurate delivery and implementation of plans

Through a variety of scheduling strategies in the ZQ-APS system, the balance of capacity, efficiency and load is achieved

Plan monitoring and completion report management make plan execution highly transparen

Production staff: sign in, task, report work, Andon call, message, rationalization suggestions, learning

Team leader: dispatch, performance, shift handover, suggestion tracking, accident report

Workshop Manager: safety, quality, delivery efficiency, cost, team, environment

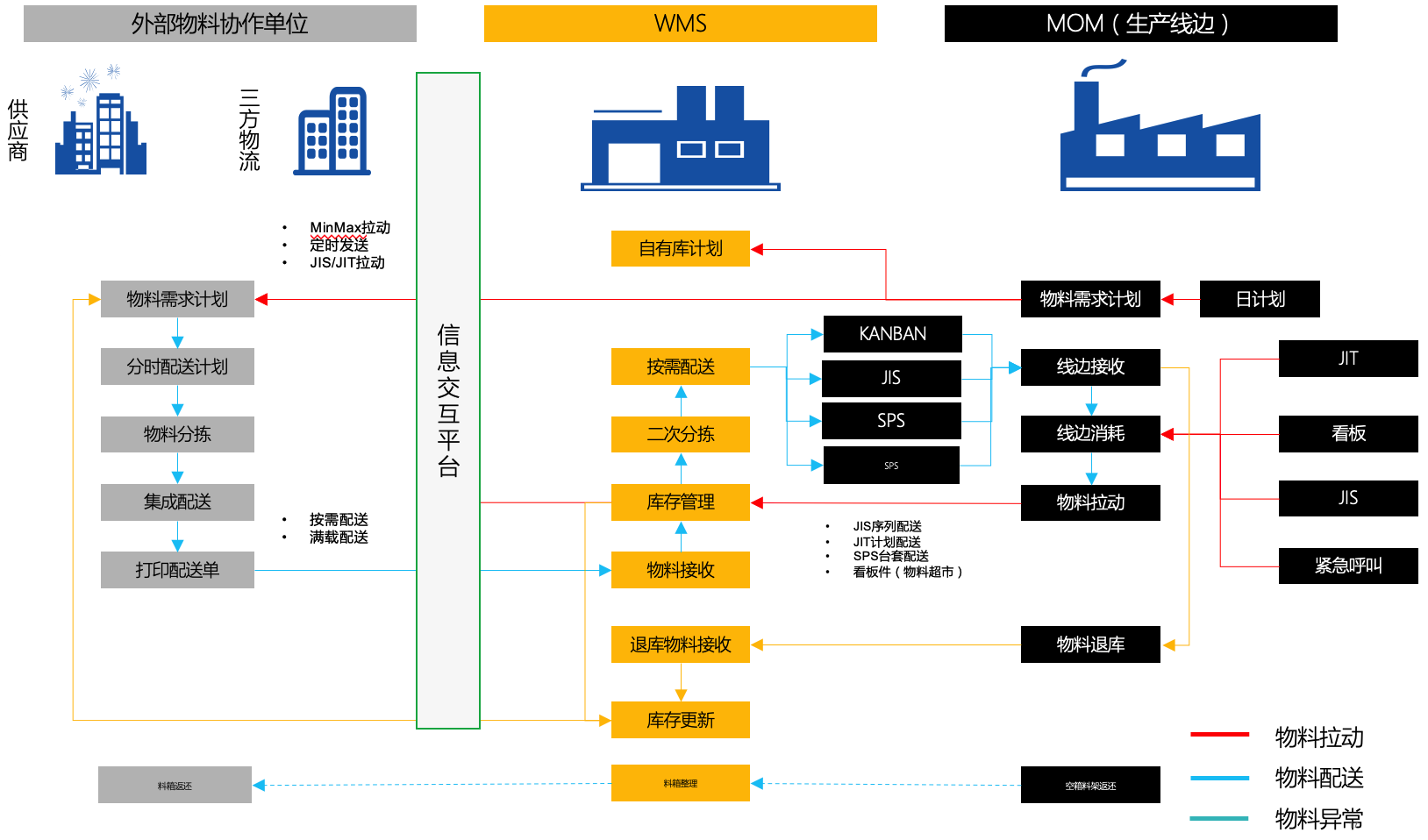

Through technologies such as data exchange and interface services, achieve collaboration between planned material requisition and logistics distribution.

Improve timely outbound delivery, precise logistics distribution, and reduce material backlog at the production line.

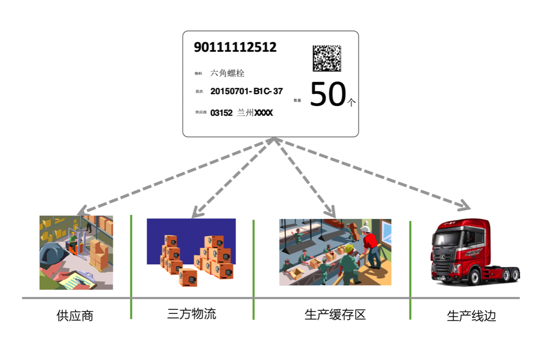

Establish scientific, standardized, unified bar code rules

Achieve one code in the end, improve the overall efficiency of the operation

Control the production and logistics process through various bar code labels

Supplier system management, let your partners grow with you

Multi-dimensional performance appraisal, monitoring supplier production, delivery, service and other indicators, establish supplier rating

Support and after-sales system quality feedback docking, quality data one-stop analysis, recovery

Realize the comprehensive sharing of quality information and complete the forward and reverse quality traceability

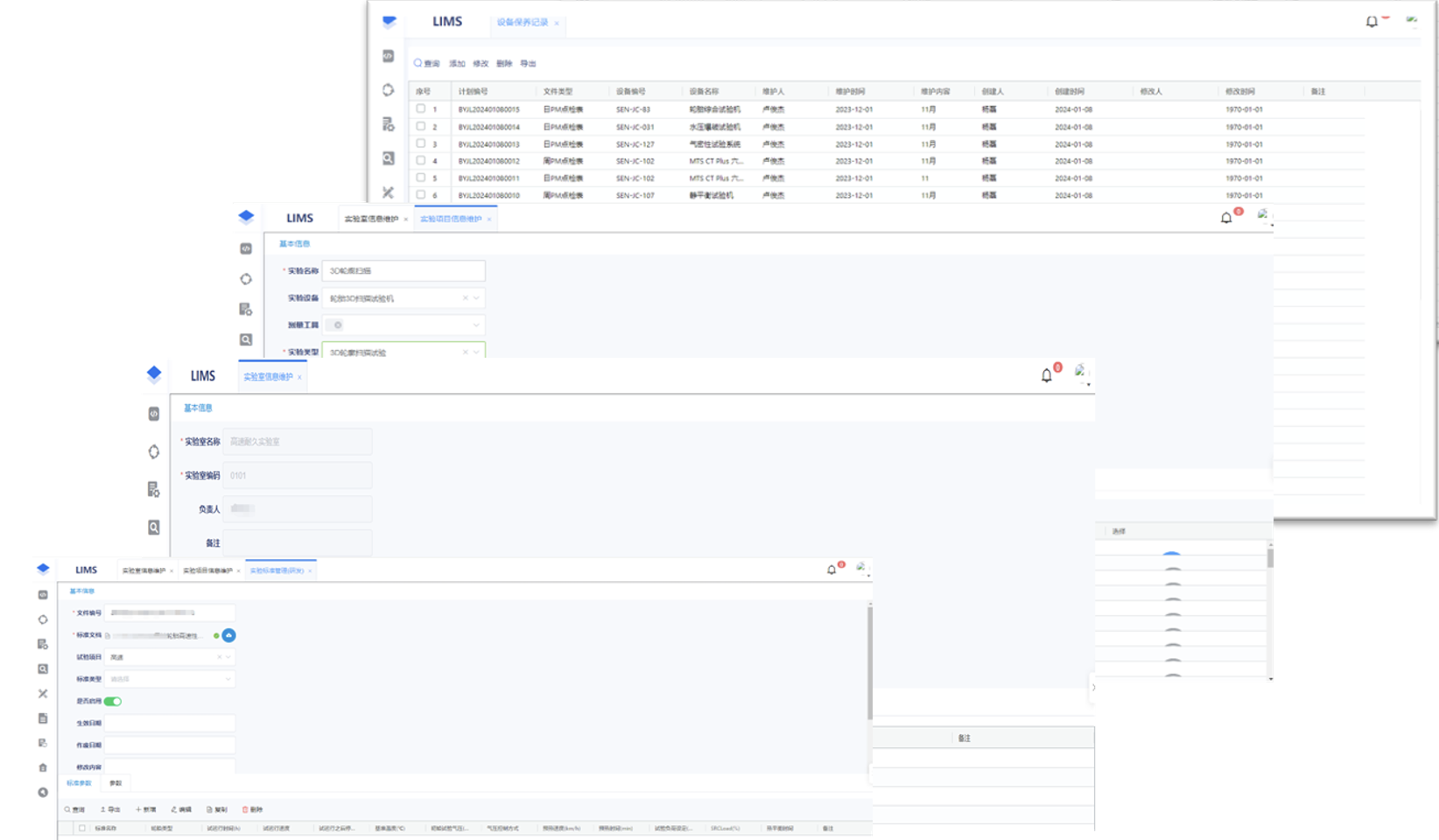

The maintenance team manages the maintenance plan uniformly, and can also manually or automatically release and arrange repair work orders.

The maintenance work order pool gathers all maintenance plans.

Automatically monitor fault information, AI algorithms help you propose preventive maintenance and improvement suggestions.

Using mobile tools to perform on-site maintenance work is flexible and practical.

Build a fault knowledge base to make maintenance smoother and form enterprise knowledge assets.

Production staff: sign in, task, report work, Andon call/message, rationalization suggestions, learning

Team leader: Dispatch, performance, shift/suggestion tracking, accident report

Workshop Manager: Safety, quality, Delivery efficiency/cost, efficiency, team, environment

System manager: user, system parameter setting

Fully supports multiple standard protocols, CNC systems, PLCs, etc.

Comprehensive response to machining equipment, assembly equipment, testing equipment, laboratory equipment, energy equipment, etc.

Safely and quickly collect device data to solve data loss caused by storage and PLC response time differences.

Edge computing improves the interaction efficiency between platform devices and device devices.

Support future oriented data application expansion.

Cross-application data fusion calculation completes data extraction-transformation-loading

Integrate the powerful Exceptionless distributed log to troubleshoot exceptions

Help enterprises quickly build data pipelines between heterogeneous data sources

The connection of each object can be completed through configuration to meet the individual needs

Check energy consumption data, reports, warning alerts, etc. at any time, and trace all information departments.

Multiple ways to push various types of warning information, supporting client pop ups, APP message reminders, SMS, email, etc.

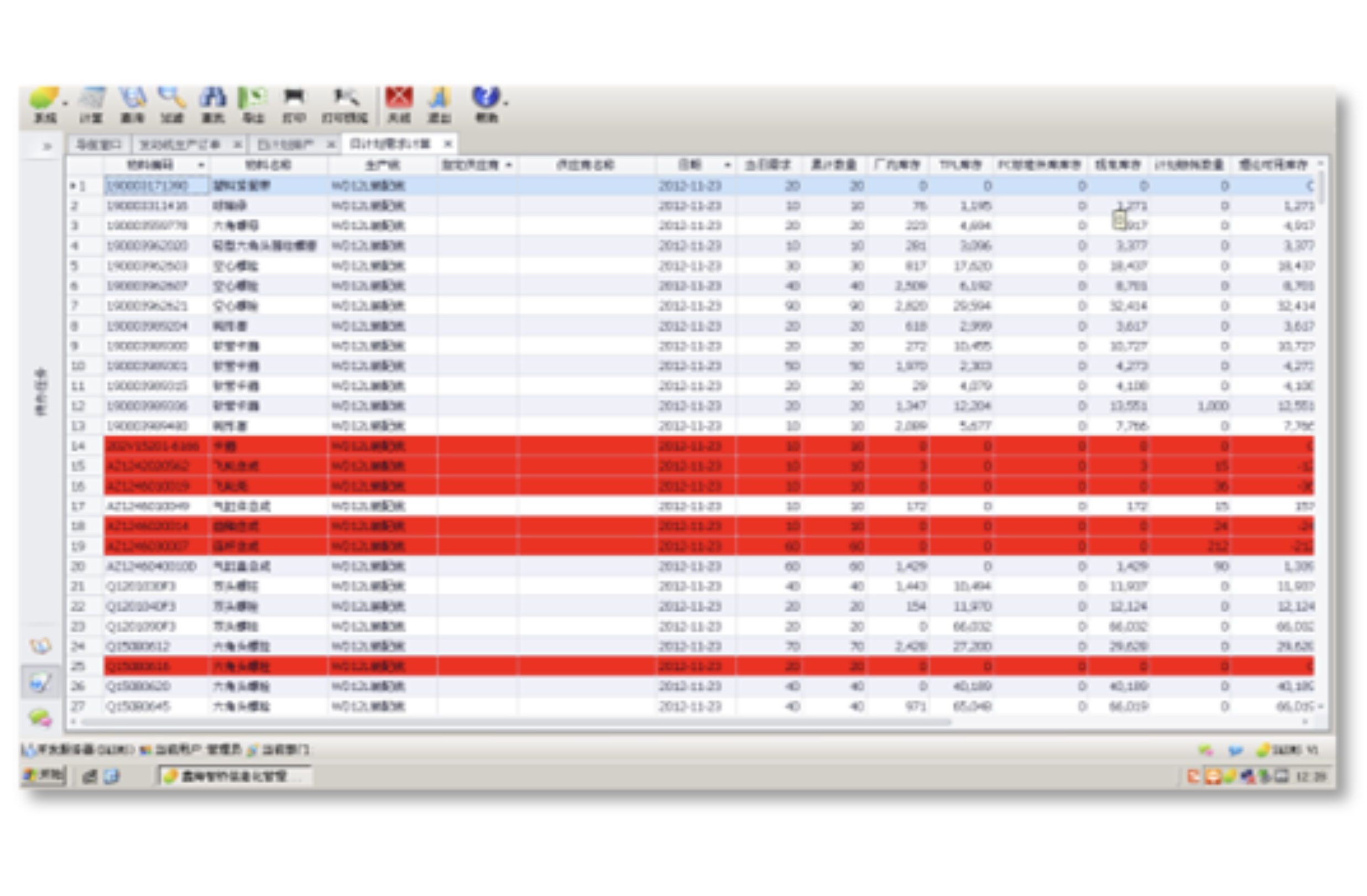

Real time tracking and management of spare parts, facilitating enterprises to grasp the inventory status of spare parts at any time.

Develop a scientific inventory management strategy to ensure that spare parts inventory is within an appropriate range.

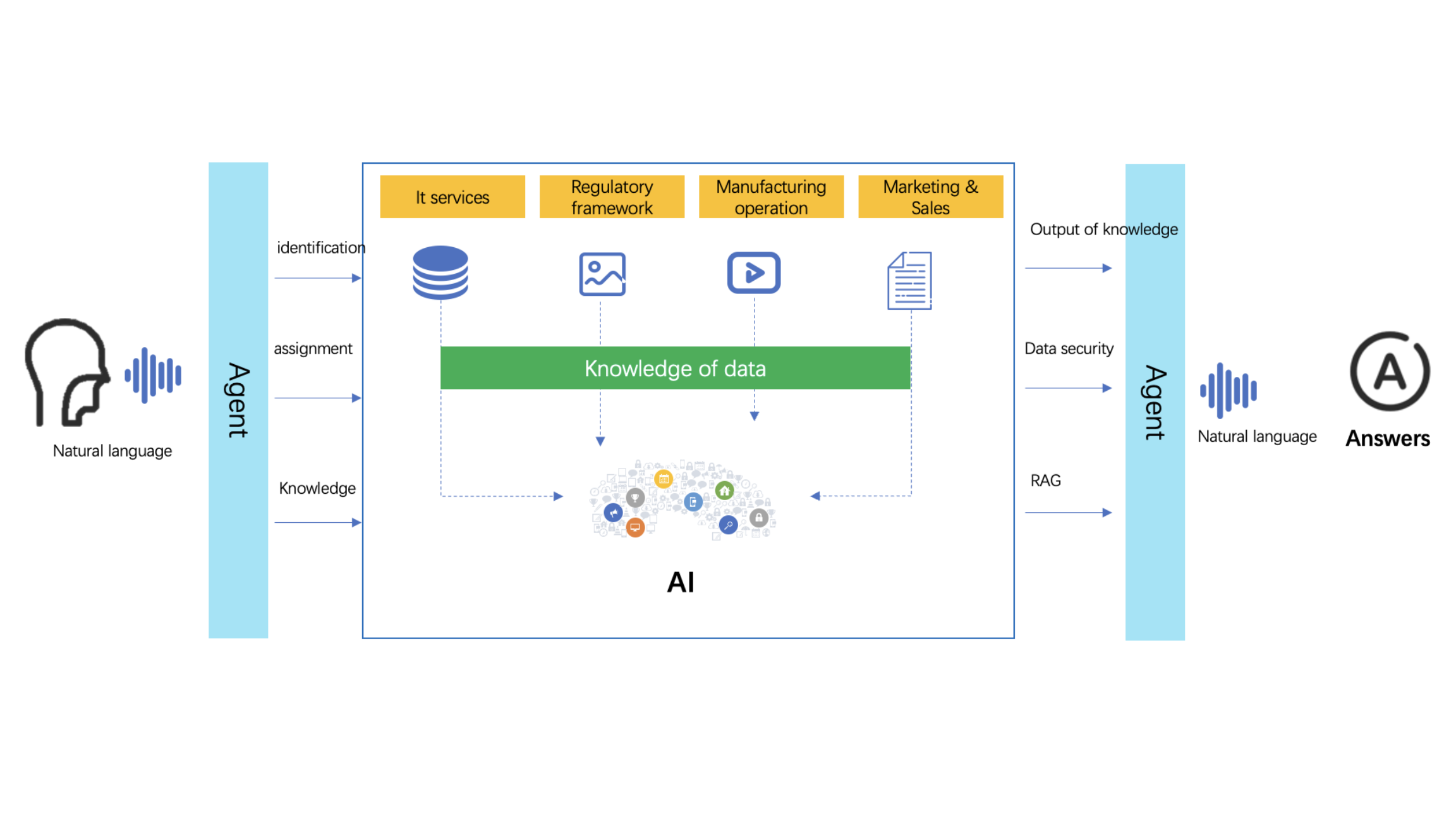

By combining speech models, large-scale models, and vectorized models, we aim to build powerful multimodal capabilities to meet the intelligent needs of data in multiple scenarios.

Through RAG technology and prompt optimization, precise intent recognition and efficient SQL generation are achieved, improving data interaction efficiency.

Provide complete data intelligent Q&A function, provide reliable support for enterprise decision-making, and assist in digital transformation and intelligent upgrading.

Purchasing and receiving, quick inbound and outbound, incoming quality inspection, shelving and inbound, in stock management, planned outbound, return and reverse warehousing, everything is available.

The FIFO system combines multiple logics to keep materials always "fresh" and keep your outbound time "clear".

Seamless integration between material requirements and outbound actions, the terminal is your outbound tool.

The system begins with management and finally digitizes. ZQ-MES fully considers business process reengineering optimization, operation lean thinking, and system solidification

Provide improvement support for lean production optimization through data analysis

It fully supports Web, PC, MOP, PAD, PDA, APP, TV and other terminals

Terminal data hyper-fusion, business end, executive end, management end, three-terminal interconnection

Embedded social components, voice, picture, text, message interaction, make communication smooth

Combined with MBOM management, the differentiation is calculated to facilitate the identification of difference items by personnel

The material requirement list is automatically generated, so that the production material is clearly visible

The system automatically calculates the material requirement plan to provide efficient support for supply chain collaboration

Seamless connection with MES, PDM, ERP, APP

Realize the basic information coordination, material demand coordination and order delivery coordination of the enterprise production workshop

Supervise safety, quality and cost effectively, reduce cost, optimize manpower and improve efficiency

More accurate MRP calculation, improve requisition accuracy

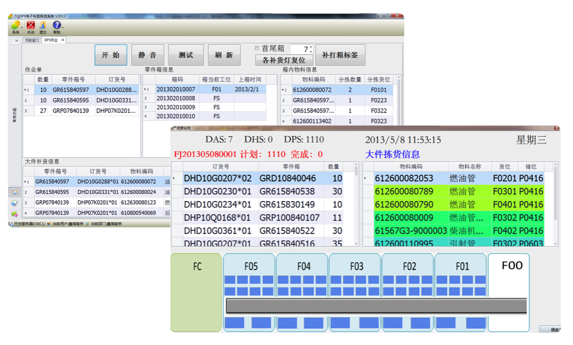

DPS electronic sorting, improve sorting accuracy

Multi-dimensional pull management to improve pull accuracy

Factory inventory Management:Provide parts inventory inquiry, facilitate timely production and logistics arrangements

Supplier Inventory Management:The factory can maintain and query the inventory of suppliers, make production plans and arrange procurement reasonably

Material reconciliation:Automatically calculate the material information that should be settled, improve the efficiency of reconciliation between factory and supplier

Through SPC, quality control KPI, Plato, CPK and other statistical analysis techniques, improve process prevention and diagnosis capabilities

Scientific adjustment and improvement of machine and process based on real and accurate data

Real-time monitoring quality data, abnormal alarm and related responsible person, improve the efficiency of problem handling

Collaborate with ZQ-APS to achieve a balance between planned downtime and scheduled maintenance, greatly improving the completion rate of scheduled maintenance and maximizing efficiency.

With the help of ZQ-EAM, automatically generate reports and improve the maintenance team's fault analysis capabilities. Comes with graphical reports to deliver to your team.

Combining cockpit management technology, presenting visual data to help visually view key KPI indicators.

Realize 3D real-time display of on-site human, machine and material information

Monitor workshop production, logistics, quality, equipment and other production related status information

Guide all departments to work together, flat management

A "one-stop" decision support system for management

Unrestricted by time and space, real-time device data collection.

It can be seamlessly integrated with DNC, MES, APS, ERP, etc.

More accurate plans and more scientific measures.

Capable of customizing personalized functions and interfaces according to the actual needs of users.

Has strong compatibility with CNC equipment, industrial control equipment, automation equipment, etc.

Compatible with 99% of CNC systems PLC、 Suitable for over 1000 types of industrial equipment.

Fully support a variety of standard protocols, CNC systems, PLC, etc

Machined equipment, assembly equipment, testing equipment, laboratory equipment, energy equipment and other comprehensive response

Collect equipment data safely and quickly, and solve the data loss caused by the time difference between storage and PLC response

Edge computing improves the efficiency of system-device and device-device interaction

Support future-oriented data application expansion

Break down system barriers: realize direct connection between MES and equipment, and build an efficient and seamless data interaction system.

Safe and reliable: Accurately deliver MES data, collect production information in real time, and securely store historical data to ensure data integrity and reliability.

Simple and intuitive: friendly interface, easy operation, real-time monitoring and precise control of the vulcanization process, improving production management efficiency.

Efficient and flexible: The process parameters are flexible, adjustable, storable, and traceable, meeting diverse production needs and helping enterprises upgrade their intelligent manufacturing.

Improve energy efficiency: Ensure that energy supply matches demand, avoid energy waste and excessive consumption.

Optimize resource allocation: By planning energy demand, supply, and storage reasonably, avoid situations of energy shortage or surplus.

Avoid leakage: Monitor the energy supply and consumption at various stages of energy storage, conversion, transportation, and use, evaluate the energy consumption at each stage, and promptly detect leakage and abnormal energy use situations.

Realize comprehensive tracking and management of spare parts, timely understanding of their usage and inventory status.

Through automated management methods, reduce manual recording and search time, and improve work efficiency.

All materials, equipment, packaging, factory information, role personnel, and customer file information are controlled.

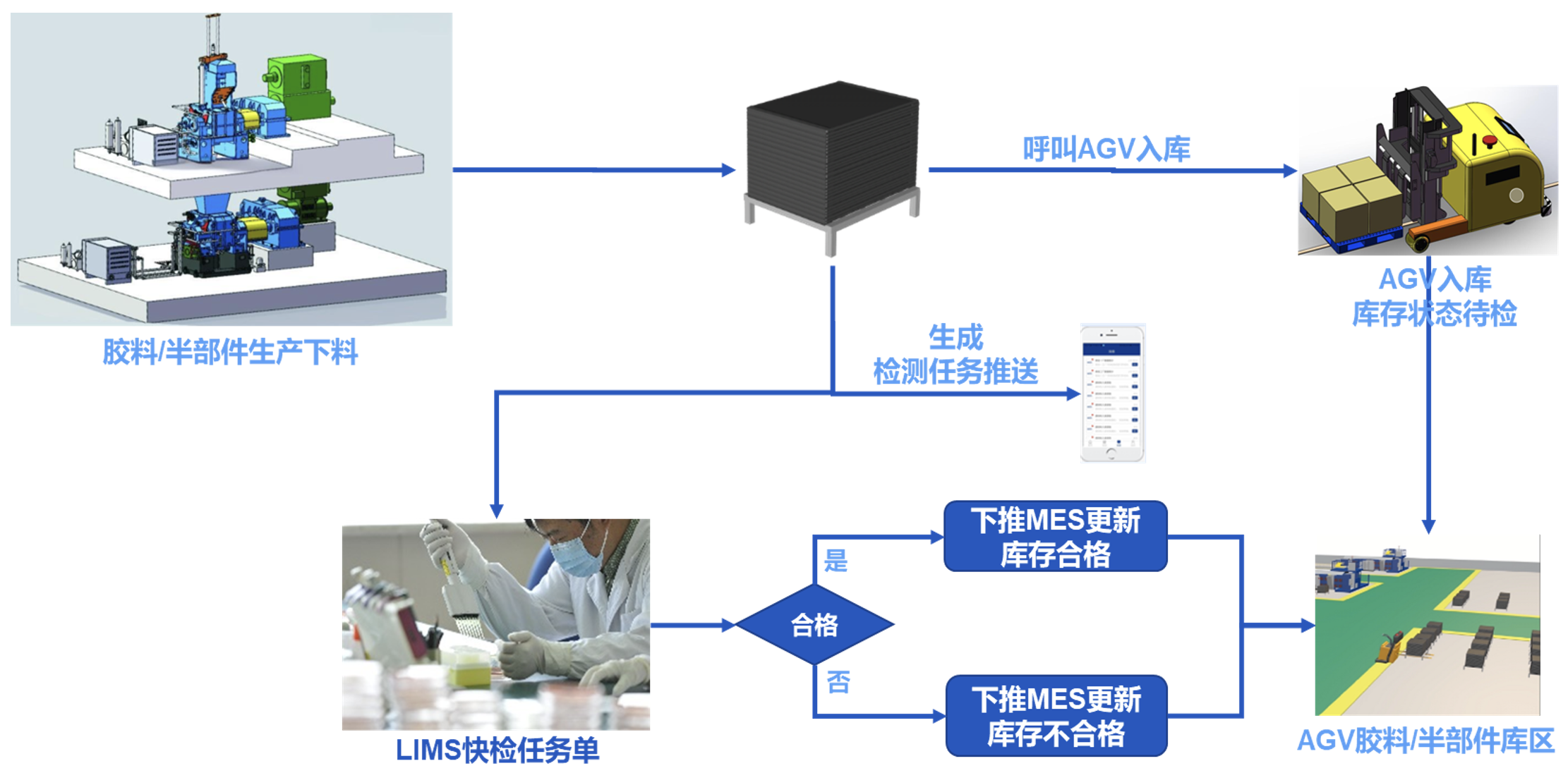

Automatic triggering of incoming information reduces the passive detection of pending inspection information by quality inspectors and improves the efficiency of incoming storage.

Supports various types of storage formats such as flat storage, shelving, and three-dimensional storage.

Utilizing the flexible safety stock strategy function, combined with ZQ-APS, to achieve intelligent material warning.

Data acquisition technology is used to map real data of human, machine, material, method, ring and measurement

ESB bus technology is used to integrate the data of each system into the data pool to avoid data island

Use data analysis models and algorithms to make management decisions more accurate

• Perform adequate digital simulation, analysis and optimization

• Information transfer from production design to field execution data unification

• Process planning (virtual world) → Manufacturing execution (real world)

Whether long-term or short-term plans, are optimized, compared, and executable

Simulate parallel resources to plan for limited resources

At the same time, constraints such as resources, capabilities, requirements, and processes are checked to optimize the scheduling

Big data accumulation, constantly enrich the knowledge base in practice, self-learning and optimization in operation

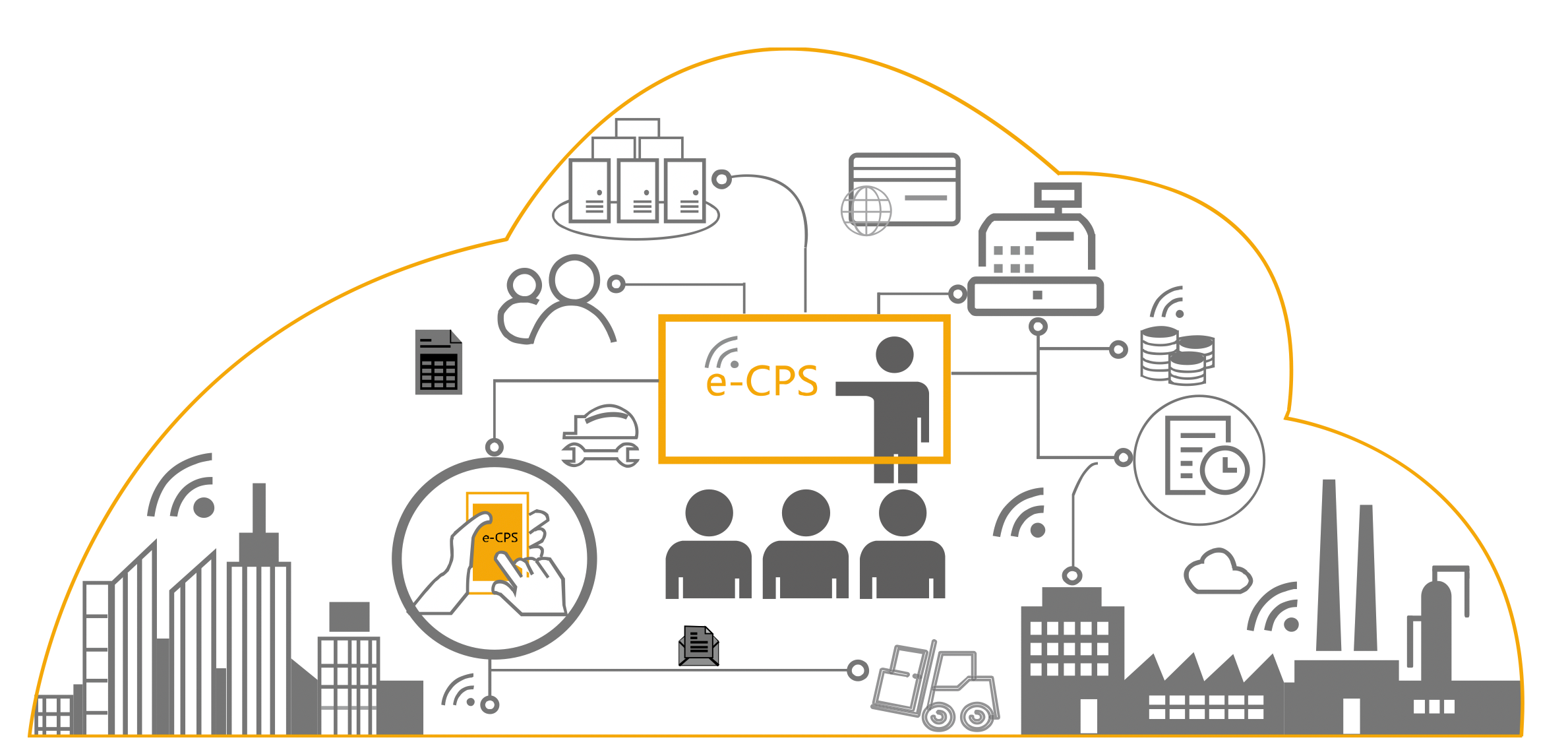

Relying on the SAAS platform, it integrates cloud computing and big data analysis

Mobile intelligent terminal equipment in one intelligent system

The interaction with the physical process is realized through human-computer interaction

Process control of picking operation, real-time display of work progress

Light to guide the picking operation, highly automated

Standardize the layout of warehouse shelves, improve the quality of packaging and strengthen the protection of parts

Use quality traceability technology to complete the quality recovery of suppliers through the platform

Supplier incoming quality self-inspection list, paperless management, into the quality traceability system

Prevent suppliers from malicious modification of batch information, and use the system to improve the rationality and accuracy of incoming material information

Data driven business continues to grow, add value, and upgrade.

Equipment management is centered around operational data analysis, collecting and managing all data and information, combining real-time big data and machine learning to predict and analyze equipment performance, and make optimal decisions.

Easy access to enterprise business systems, breaking the data island

Deep interactive analysis, full dimensional display of graphs and charts

Different roles are assigned to corresponding data and kanban boards

Meet the business data needs of personnel at all levels and positions

Transparency, data speak

Fully support app, web, small program, provide targeted solutions

Touch large screen, TV kanban board, tablet, mobile phone and other mobile terminal display

Cover multi-role, full scene, one-stop solution to the problem

Not limited by time and space, real-time equipment data acquisition system

It can be seamlessly integrated with DNC, MES, APS, ERP and other systems

Plans are more accurate and measures are more scientific

According to the actual needs of users, personalized functions, interface customization

Real time collection and establishment of energy consumption data dashboard.

Monitor the operation status of key equipment to ensure energy supply.

Provide multi-dimensional analysis reports on energy consumption, presenting energy usage status from multiple perspectives.

Calculate and analyze energy consumption levels and energy efficiency.

Realize energy cost sharing and provide energy consumption bills.

By tracking and controlling the status of spare parts in a timely manner, it is possible to achieve the protection of equipment's' fine water, long flow ', thereby improving equipment efficiency and enhancing equipment stability.

Reasonable spare parts management can reduce the idle and waste of spare parts, and lower the inventory cost of spare parts.

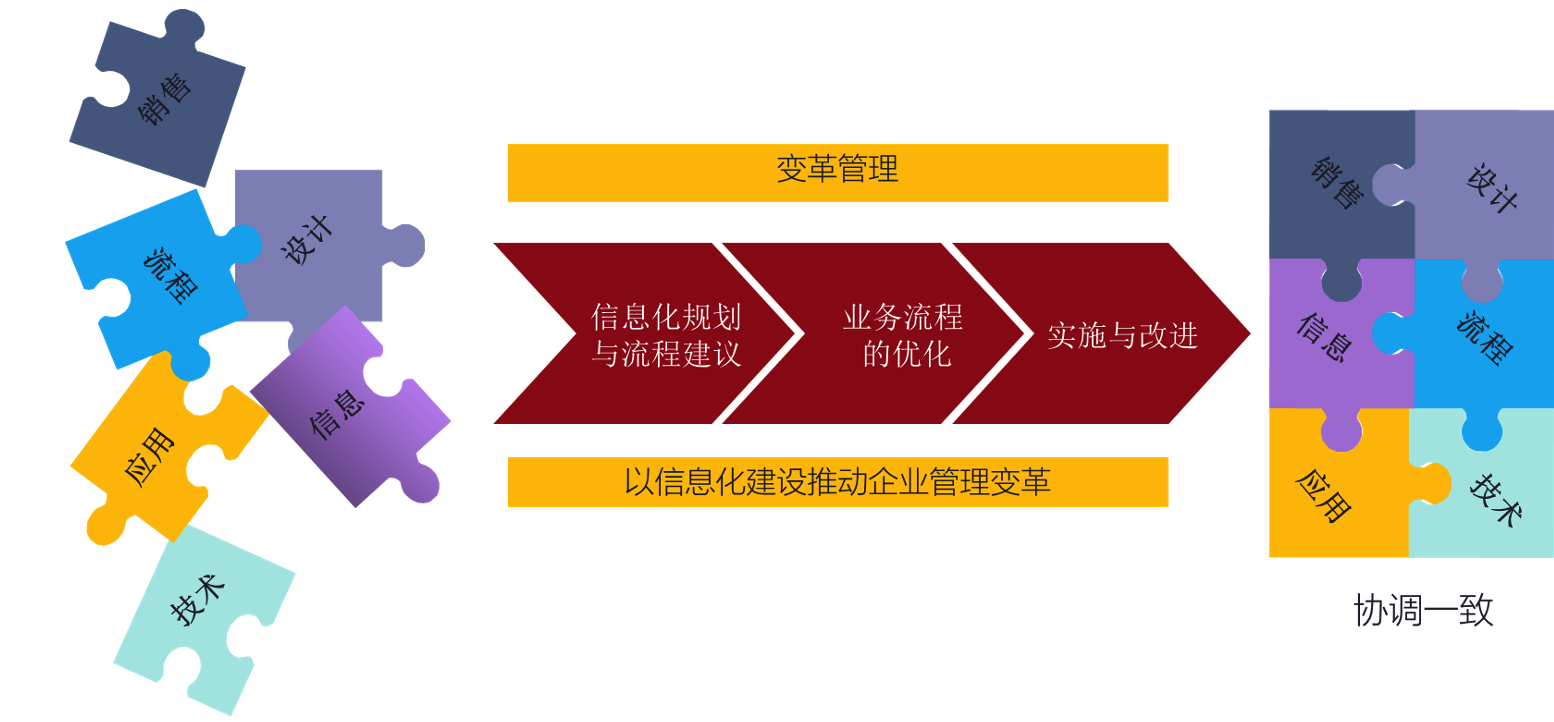

Standing at a higher height, planning the future factory

With the rich and convenient expansibility of the platform, it is implemented step by step to reduce the difficulty of the project

Enterprise IT strategic planning, phased investment, small costs, large benefits

Standardize production, processing and other equipment management

Improve equipment production efficiency, reduce equipment investment

Strengthen employee performance appraisal and improve the efficiency of quick response and handling of exceptions

Improve key operations automation management, reduce the input of manpower and material resources

According to the principle of lean production, the flexible production mode is established

According to the job task requirements, an optimal structure is formed by itself

Quickly respond to exceptions and order changes, and plan the whole process without worry

Human-computer interaction, simplified operation and data analysis are realized

Set mobile Internet, point-to-point information transmission and other functions in one

Realize the interconnection of personnel, equipment and information, and achieve agile response to things

The ZQ DPS system automatically prompts daily BOM changes

Real time changes in virtual parts are reflected in sorting, and BOM can be flexibly modified

Shift management, fixed personnel positions for system operations

Storage location management, where storage locations correspond to materials and have priority levels

One code to the end, full traceability of materials and traceability of operators

Quality control point migration, complete supplier basic inspection

Upload supplier delivery inspection records

Inspection records are attached to shipment

Realize the whole manufacturing process quality management of "incoming material quality inspection - process quality inspection - finished product quality inspection - after-sales quality"

Set up standard quality system and control production process based on quality dimension

Real-time analysis and display of quality KPI, find quality problems and formulate quality solutions

Break system barriers and build industrial big data

The integration and centralization of services are realized through enterprise service Bus

Connect flexibly with standard interfaces for true on demand

All operations and data are recorded in real-time and cannot be tampered with, ensuring data authenticity and real-time analysis of enterprise cost control.

Ensure the accuracy and consistency of spare parts data, and reduce human errors.

Support multiple data analysis methods, provide statistical analysis of spare parts inventory, inventory status, spare parts history, spare parts attendance rate, etc.

Barcode-based management is implemented at the production site to ensure an efficient and standardized process.

Samples are automatically linked with production materials, enabling seamless data integration and improving management efficiency.

With an intelligent system, the entire sample management process is traceable, ensuring quality, safety, and process transparency.

Test results are automatically determined based on system-defined standards, ensuring accuracy and consistency.

The manual review process supports flexible configuration, catering to personalized needs in different scenarios, achieving efficient management.

Equipment records and historical data are fully traceable, ensuring transparency and visibility of equipment status.

Measurement and calibration plans are automatically generated with timely notifications, preventing any oversights.

Deep equipment integration allows for automatic acquisition of testing and inspection data, achieving efficient automated management.

Reports are generated automatically, improving efficiency and accuracy.

Customizable report templates are supported to flexibly meet diverse needs.

Original records and reports are automatically generated, ensuring standardized management and process compliance.

The system fully supports PC, tablet, and large screen displays, meeting the needs of various application scenarios.

Real-time synchronization of information across multiple terminals ensures efficient collaboration between devices, delivering a seamless management experience.

Omni-channel data pool, one-stop collection and monitoring of business indicators

Large screen visualization of data, more intelligent control scene experience

Provide a complete library of graphical interface components based on HTML5

A complete set of 3D graphics engine, directly linked to the database, production line digital twin

You can easily build modern, cross-desktop and mobile enterprise applications

Understand the cause of data anomaly, manage the cockpit and control the overall situation

Business data KPI, drag-and-drop operation, independent analysis, enabling analytical thinking

Mobile BI, let the decision in the "palm" grasp, anytime and anywhere for managers to see the production situation, command decision-making

AI prediction, business-oriented augmented intelligent analysis, and cooperate with the university's own data science team to create deep application scenarios such as sales forecasting, intelligent diagnosis, and trend analysis

Our strengths: end-to-end service capabilities

Xinhai Zhiqiao has strong ability to support strategic and business consulting, digital system platform construction, OT technology integration, operational decision-making and project completion

Comprehensive coverage from intelligent manufacturing planning to software implementation and deployment, hardware integration, and the final realization of digital business value

Adhering to the integration concept of starting from management and finally digitalization, we have completed a deep insight into the industry and business

Accurately understand customer needs and business demands, and play a neutral role as a consultant

Consistently provide customers with highly valuable digital solutions

With rich project experience, Xinhai Zhiqiao has accumulated more than 100 practical cases

It has set up representative demonstration pilot projects and benchmark factory projects of the Ministry of Industry and Information Technology throughout the country

Relying on rich project experience, we will continue to develop and innovate