Global control of Kanban KPIs.

KPI can be viewed for different roles through tile and drag configuration.

Graphical data allows you to have a clear and visible view of the warehouse.

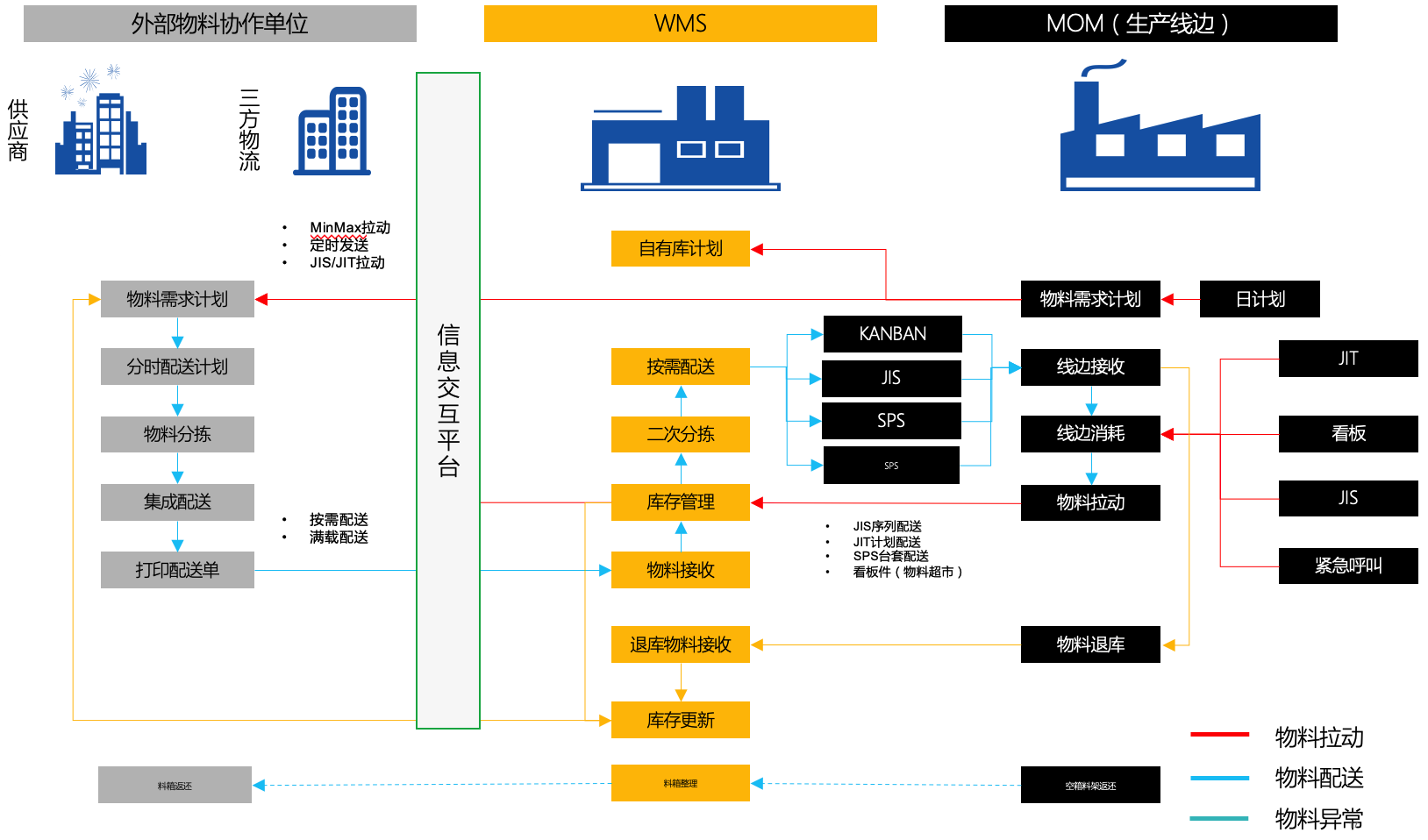

Through technologies such as data exchange and interface services, achieve collaboration between planned material requisition and logistics distribution.

Improve timely outbound delivery, precise logistics distribution, and reduce material backlog at the production line.

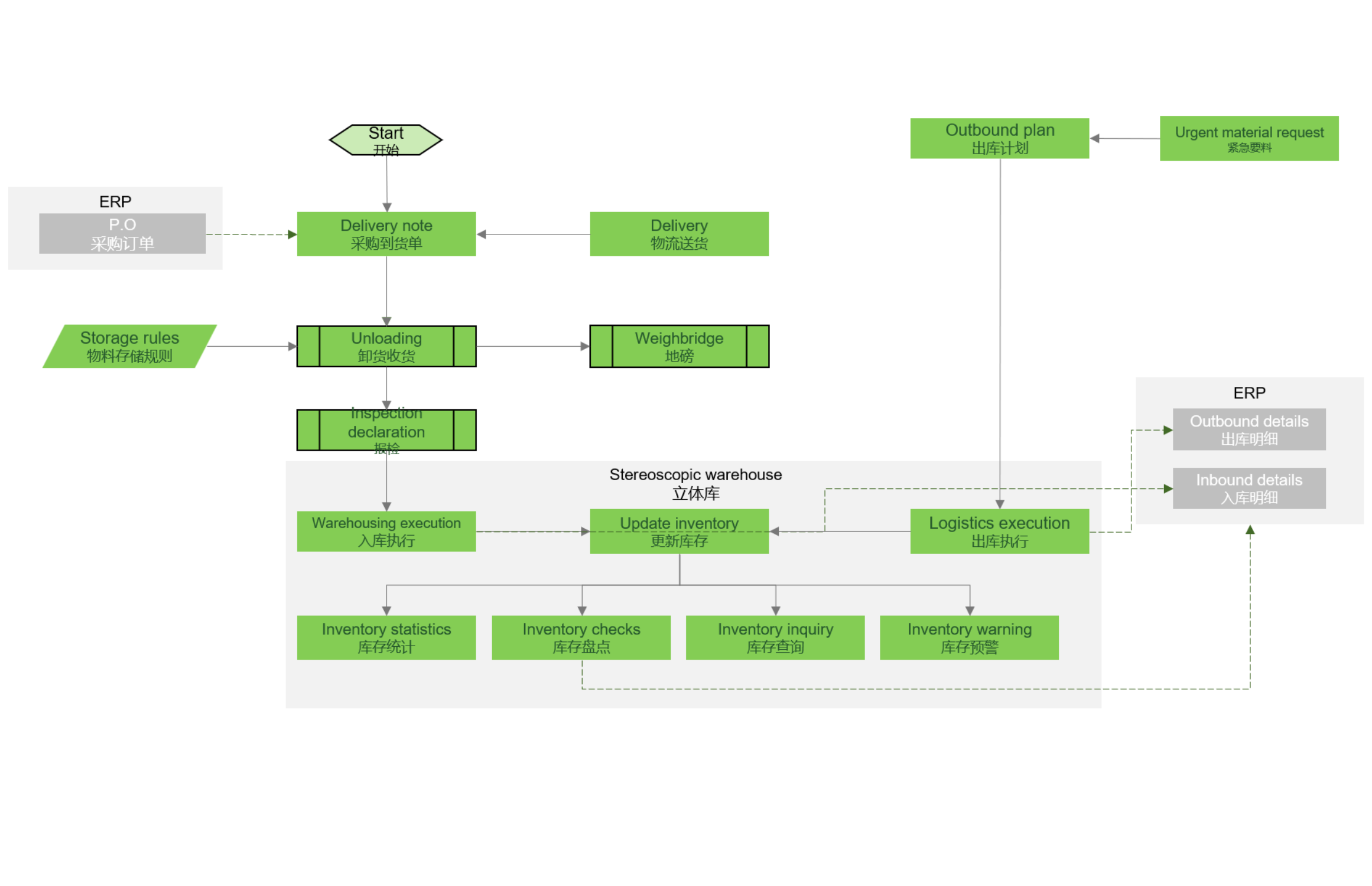

Purchasing and receiving, quick inbound and outbound, incoming quality inspection, shelving and inbound, in stock management, planned outbound, return and reverse warehousing, everything is available.

The FIFO system combines multiple logics to keep materials always "fresh" and keep your outbound time "clear".

Seamless integration between material requirements and outbound actions, the terminal is your outbound tool.

All materials, equipment, packaging, factory information, role personnel, and customer file information are controlled.

Automatic triggering of incoming information reduces the passive detection of pending inspection information by quality inspectors and improves the efficiency of incoming storage.

Supports various types of storage formats such as flat storage, shelving, and three-dimensional storage.

Utilizing the flexible safety stock strategy function, combined with ZQ-APS, to achieve intelligent material warning.