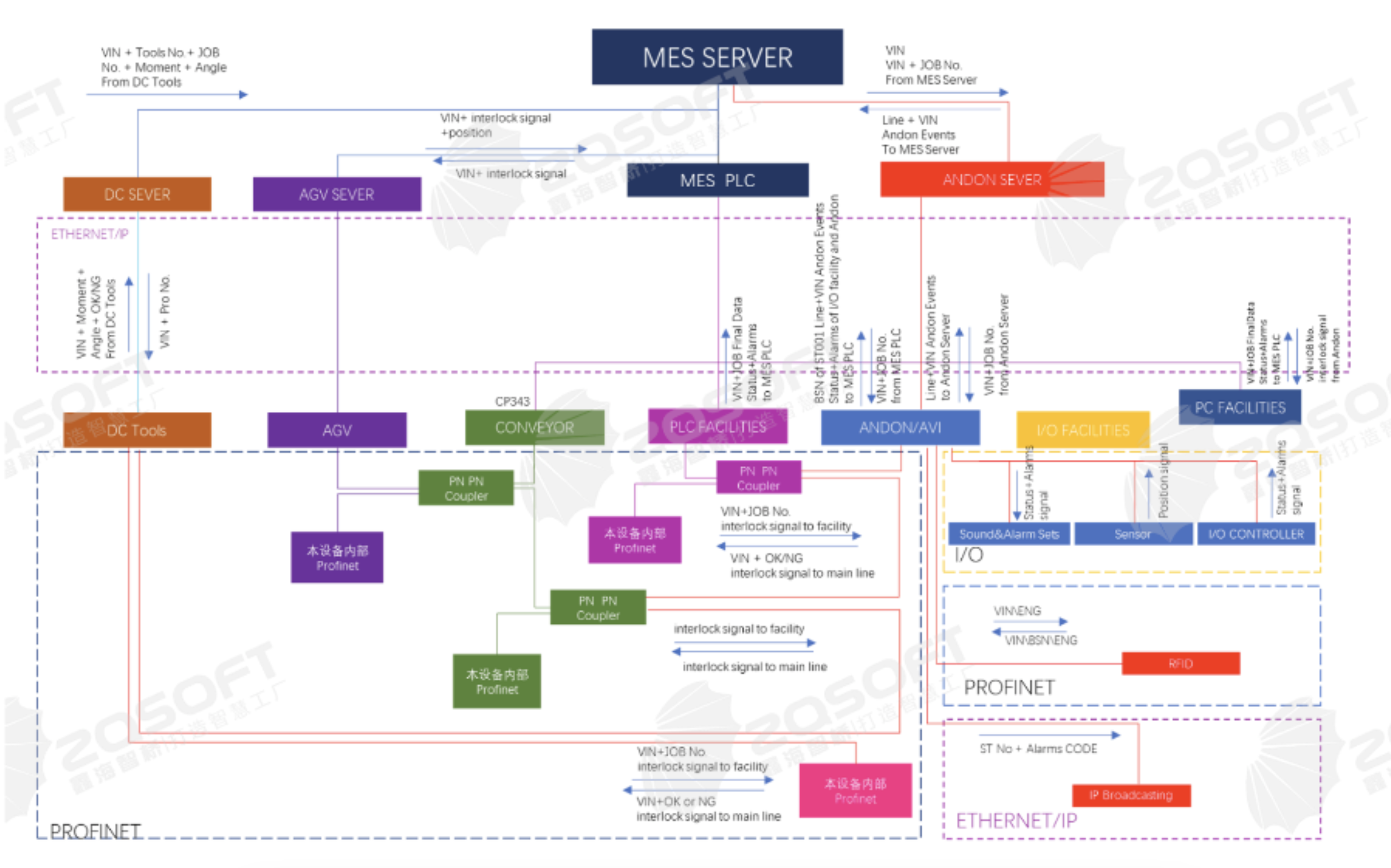

Adapt to mainstream communication protocols, operating systems PLC。

Support data recognition for multi format text.

Integrate edge computing technology to achieve rapid data response.

Professional data management mechanism to provide data security assurance.

Fully supports multiple standard protocols, CNC systems, PLCs, etc.

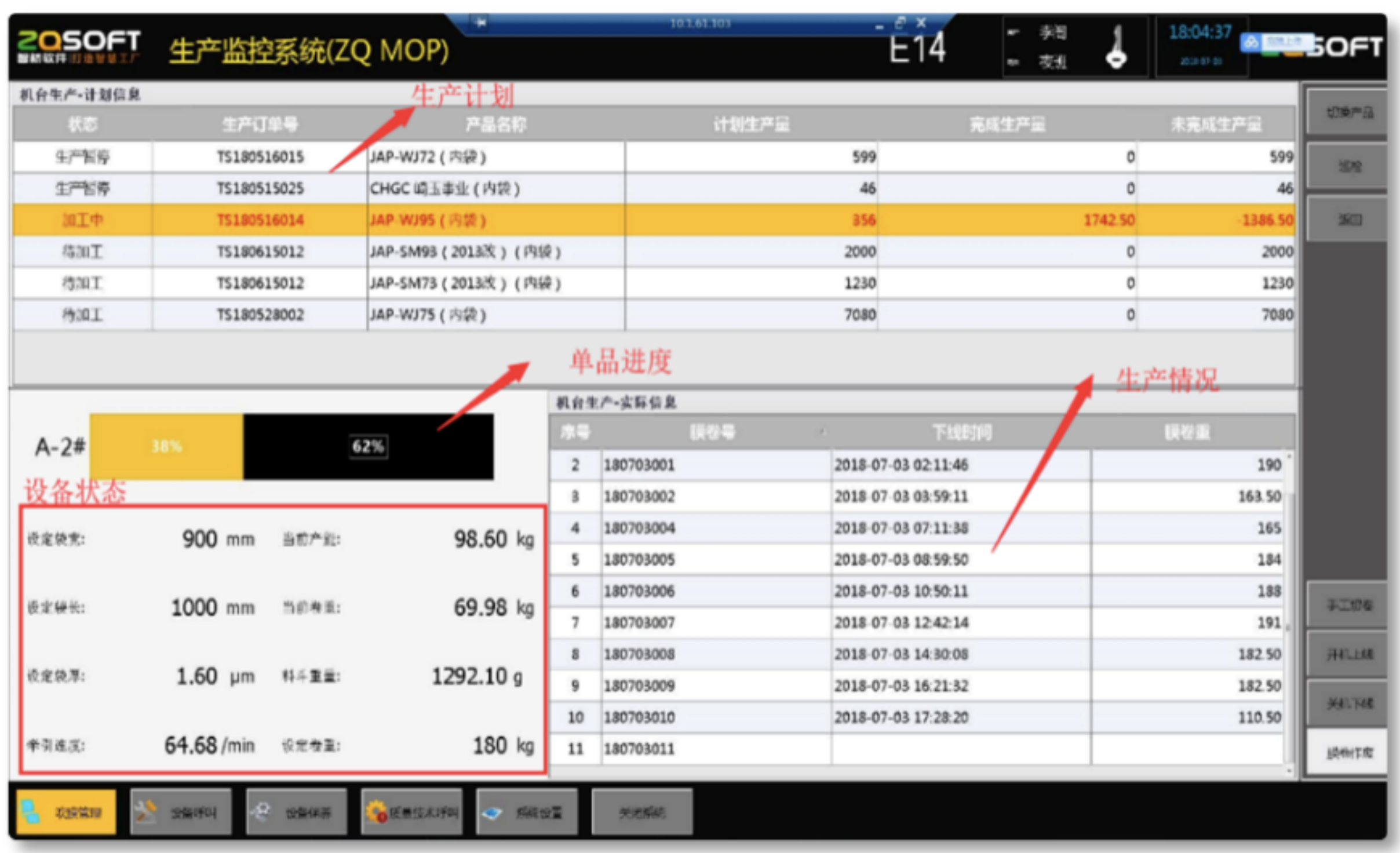

Comprehensive response to machining equipment, assembly equipment, testing equipment, laboratory equipment, energy equipment, etc.

Safely and quickly collect device data to solve data loss caused by storage and PLC response time differences.

Edge computing improves the interaction efficiency between platform devices and device devices.

Support future oriented data application expansion.

Unrestricted by time and space, real-time device data collection.

It can be seamlessly integrated with DNC, MES, APS, ERP, etc.

More accurate plans and more scientific measures.

Capable of customizing personalized functions and interfaces according to the actual needs of users.

Has strong compatibility with CNC equipment, industrial control equipment, automation equipment, etc.

Compatible with 99% of CNC systems PLC、 Suitable for over 1000 types of industrial equipment.