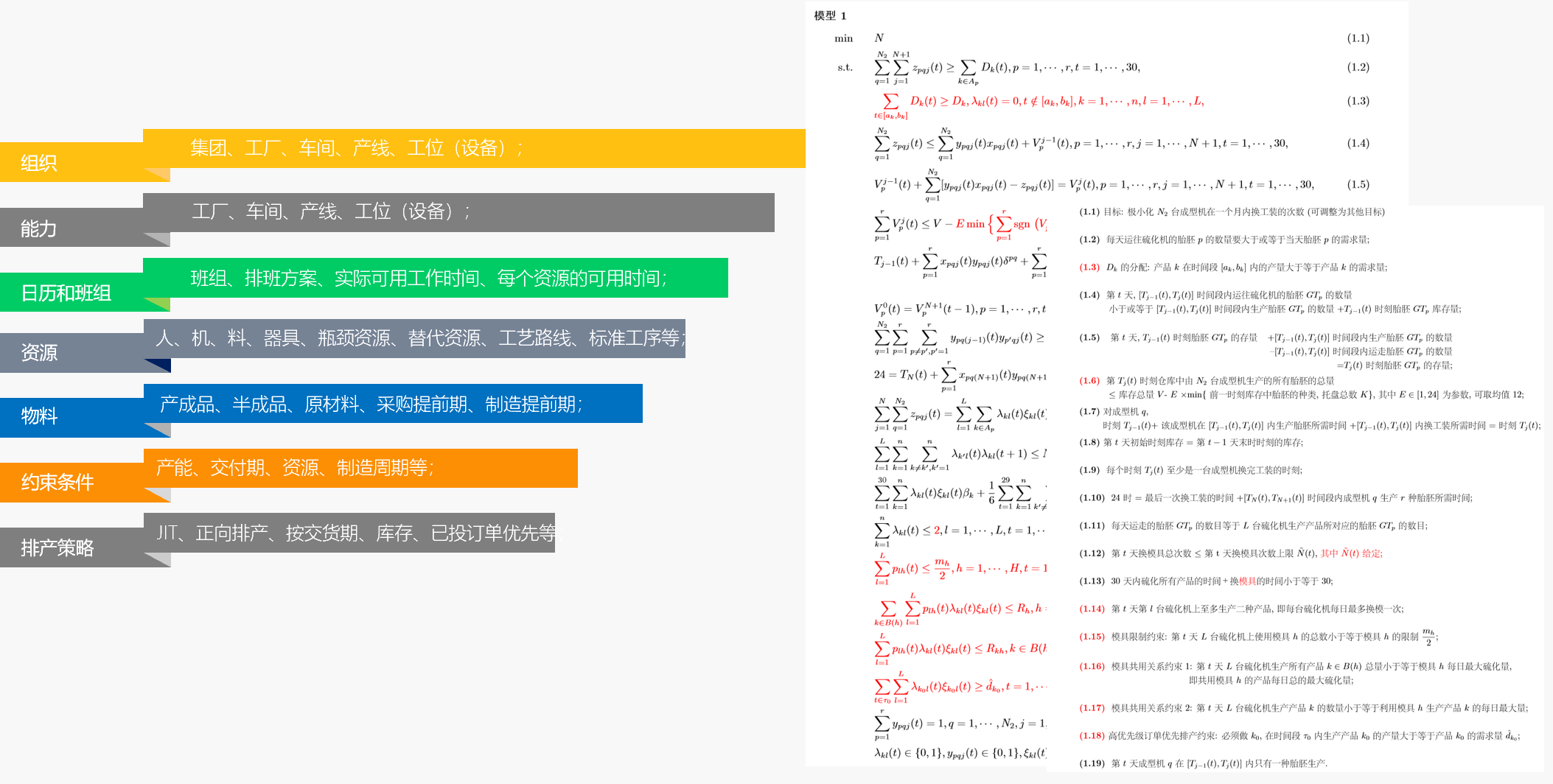

Based on the self-developed production scheduling logic model, it can deal with the production of different types of orders

Algorithm engine, precise constraints, and manual experience make the scheduling executable and operable

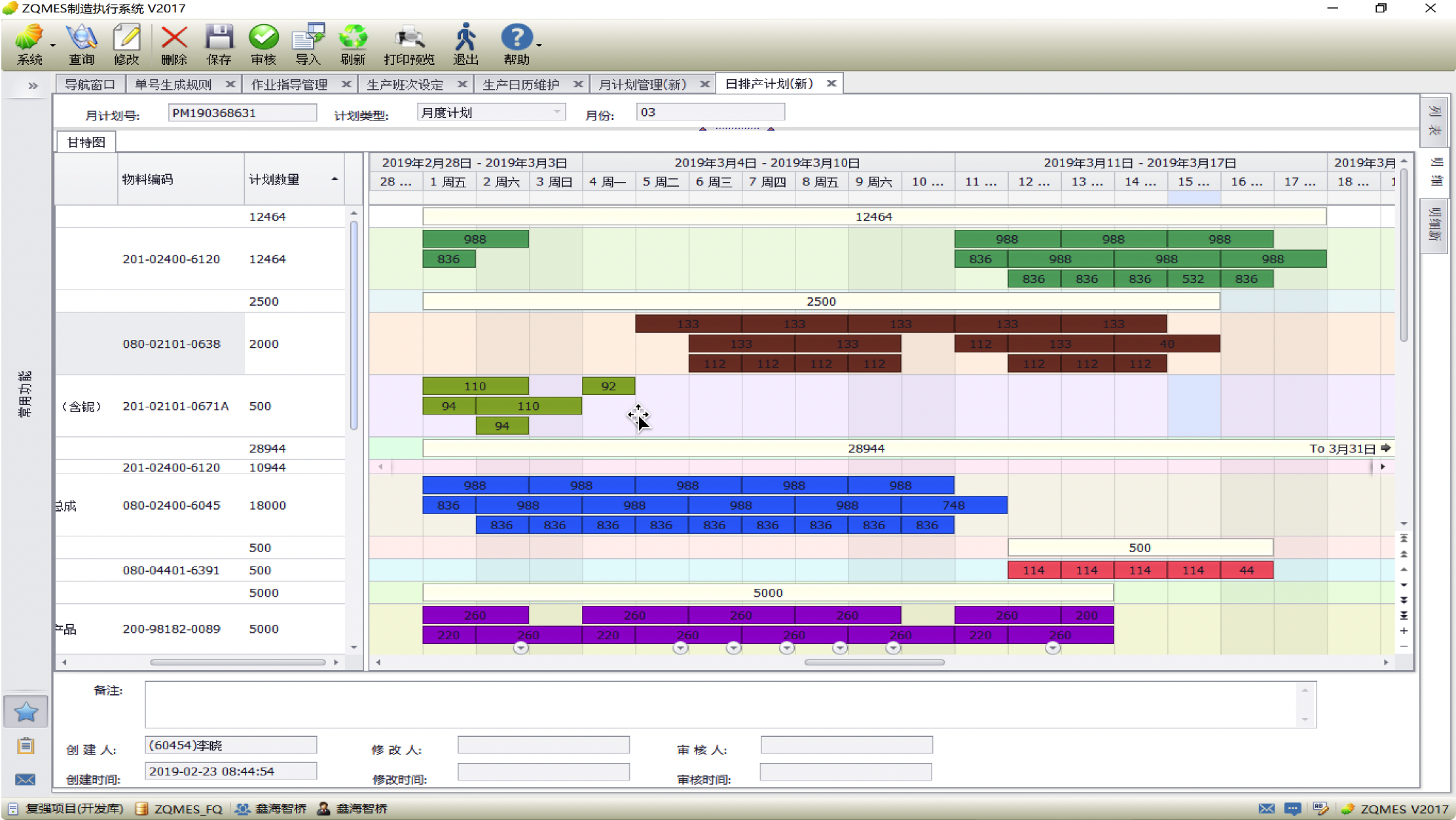

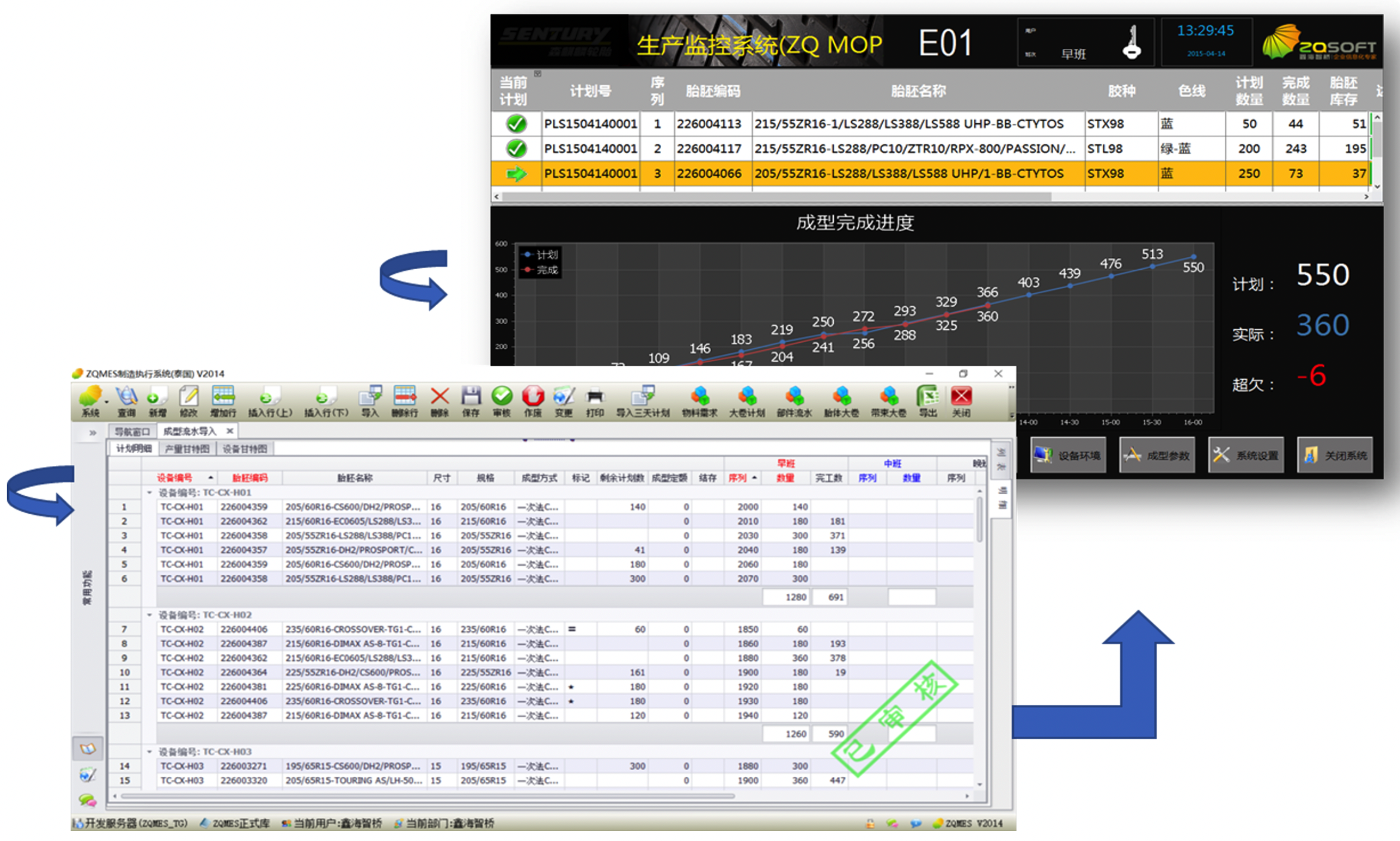

Plan-on-site linkage technology to ensure accurate delivery and implementation of plans

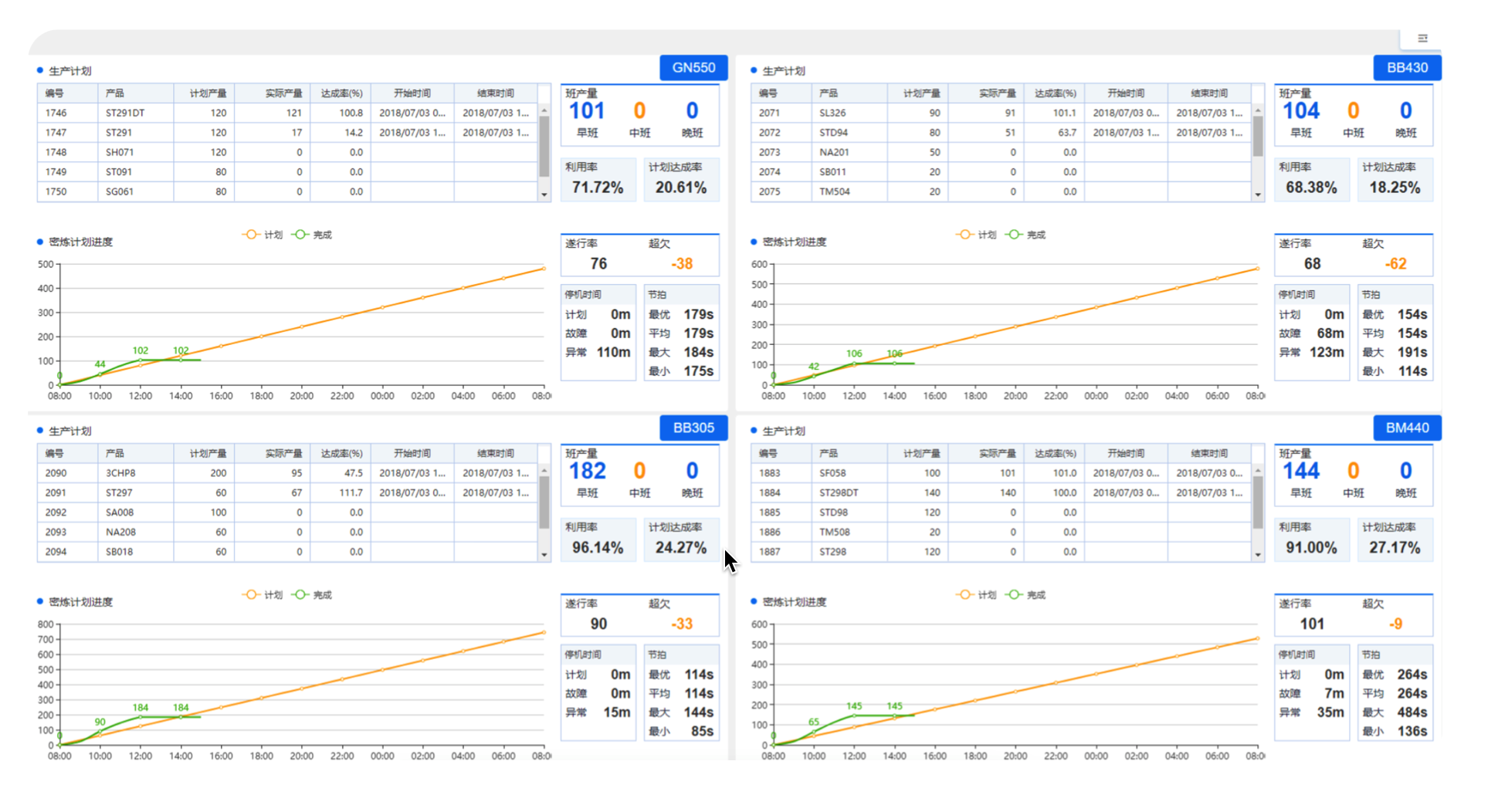

Through a variety of scheduling strategies in the ZQ-APS system, the balance of capacity, efficiency and load is achieved

Plan monitoring and completion report management make plan execution highly transparen

Combined with MBOM management, the differentiation is calculated to facilitate the identification of difference items by personnel

The material requirement list is automatically generated, so that the production material is clearly visible

The system automatically calculates the material requirement plan to provide efficient support for supply chain collaboration

Whether long-term or short-term plans, are optimized, compared, and executable

Simulate parallel resources to plan for limited resources

At the same time, constraints such as resources, capabilities, requirements, and processes are checked to optimize the scheduling

Big data accumulation, constantly enrich the knowledge base in practice, self-learning and optimization in operation

According to the principle of lean production, the flexible production mode is established

According to the job task requirements, an optimal structure is formed by itself

Quickly respond to exceptions and order changes, and plan the whole process without worry