Intelligent algorithm to meet a variety of scheduling scenarios

Multi-level planning and scheduling, direct production planning process

Panoramic resource and demand analysis, planning and demand balance control

Comprehensive control of project progress

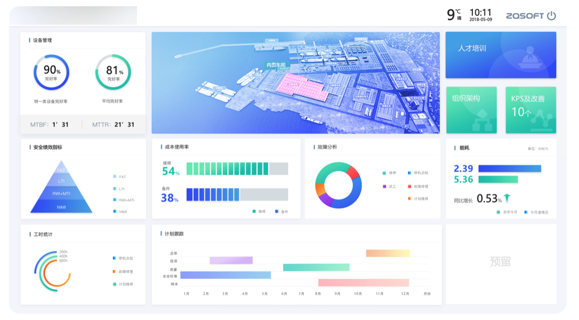

Through visual management, improve the production site management ability

Through production material tracking to achieve optimal management, improve material utilization efficiency

Achieve real-time performance statistics, strengthen production related assessment

Strengthen process quality control, automatic correlation and judgment of quality information

Strengthen process quality early warning, monitor production parameters and process deviation, effectively avoid the spread of quality problems

Enhance the ability of quality traceability, quickly and accurately carry out the whole process of quality traceability

Equipment abnormal rapid response, shorten production stagnation and waiting time

Improve the pertinence of equipment maintenance and reduce the cost of repair and maintenance

Improve equipment energy consumption management level, reduce production energy consumption