Develop long-term plans based on the overall plan of capacity

Demand and supply linkage, supply chain coordination

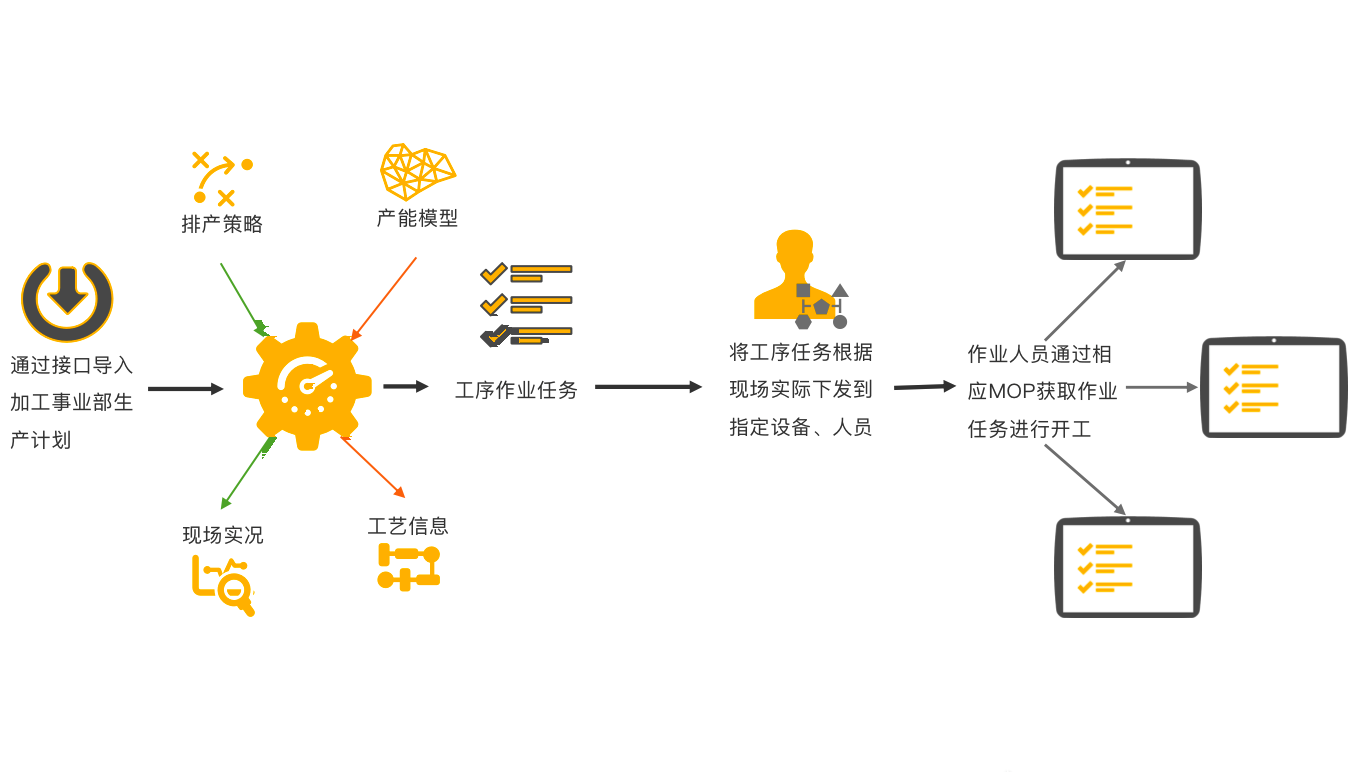

Arrange the operation plan at different levels for workshop, process and equipment

According to the actual implementation of the plan, the global plan tracking and change control are realized

Direct process of assigning and distributing production tasks

Real-time display of production information of each station or process of the production line

In the case of many types of aircraft, the technological process of different types of aircraft is well controlled

Parallel production, process/production line production beat matching each other, efficient coordination

Overall quality management, whole process quality data collection and traceability

Visualization and closed-loop control of quality event processing

Provide accurate data for managers to make decisions, improve production efficiency and product quality

Comprehensive control of equipment asset maintenance and spot inspection

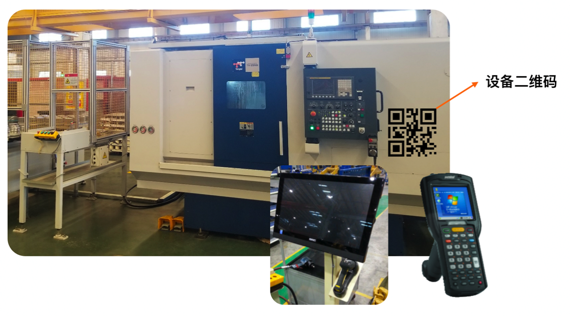

Real-time acquisition of on-site production equipment data, graphical display

Get the production quantity and online processing status of each equipment in real time

Equipment failure real-time display, maintenance personnel timely grasp, fast processing

Production monitoring and performance analysis

Capacity load assessment and process deviation monitoring

Process transparency and manufacturing decision support

Production process coordination and exception handling integrated management