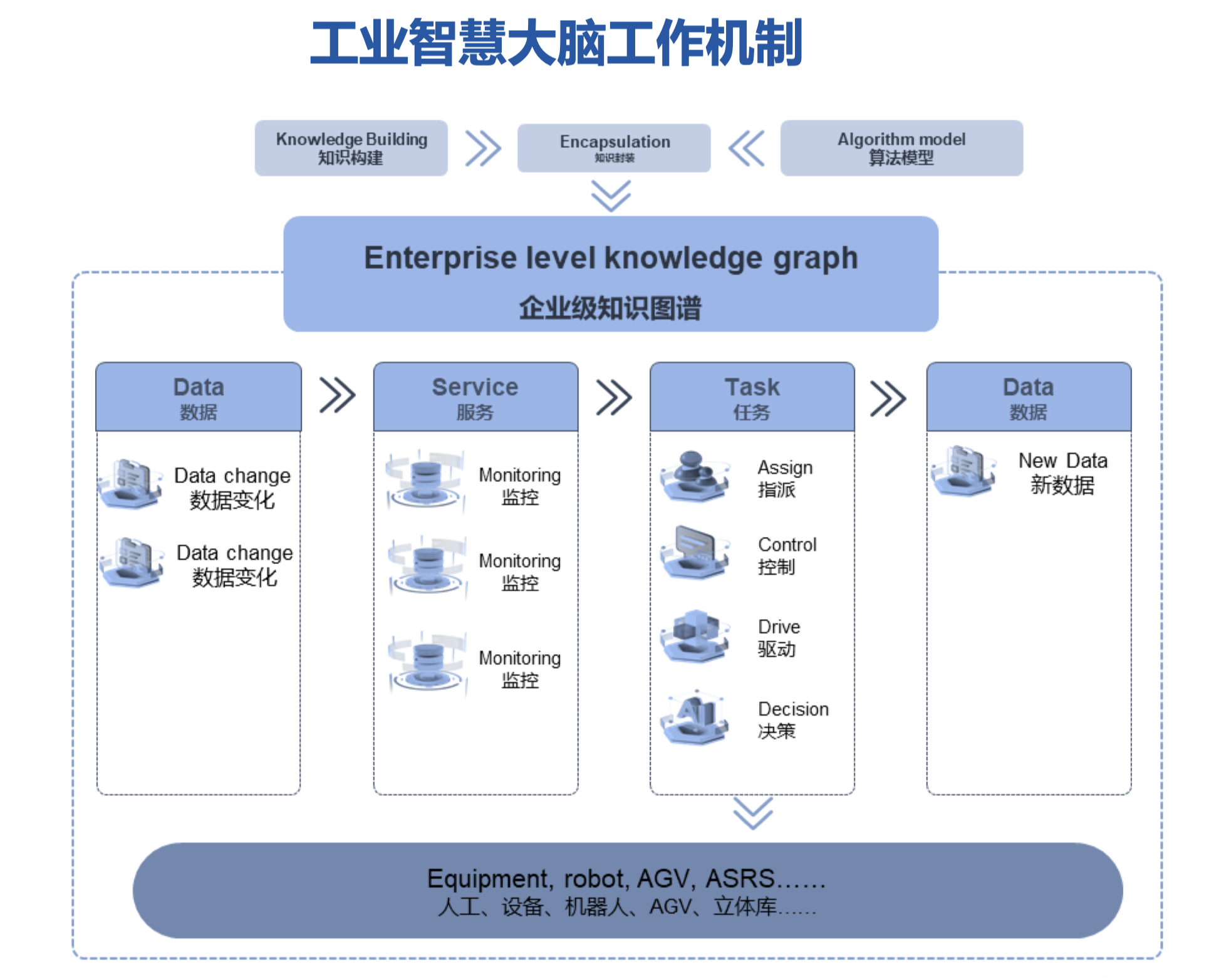

Abandoning traditional models and introducing industrial intelligent brains: By introducing industrial intelligent brains, comprehensive intelligent management of production affairs can be achieved.

Intelligent control covering the entire process: from raw material allocation to seamless integration of production processes, to quality inspection of finished products, all are efficiently controlled.

Reduce errors and time waste: Minimize human error and time loss to the greatest extent possible.

Assisting customers in enhancing market competitiveness: significantly improving product output efficiency and quality stability.

involving the digital transformation of nearly 20 tire factories.

From domestic factories to factories in Thailand, Vietnam, and Morocco.

We have accumulated rich experience in project implementation.

MES、 Raw material WMS, finished product WMS, AS scheduling

LIMS, APP platform, spare parts system, data center

Tire big model AI application, power station chain management system.

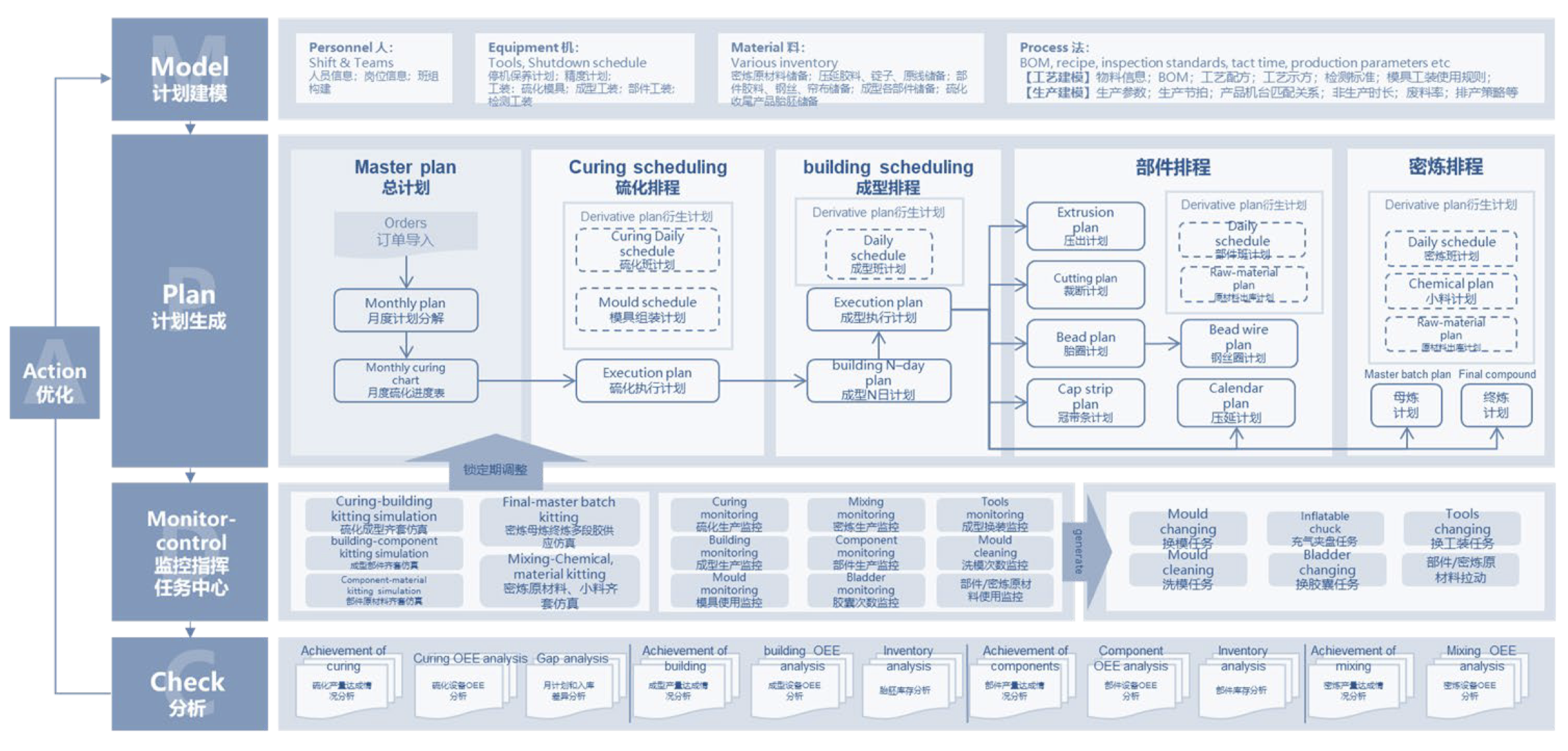

With the help of an intelligent production scheduling system, resources and time nodes are accurately matched for each process.

Based on this, optimize on-site scheduling and accurately control key information such as material inventory and equipment status.

Anticipate the risk of material shortage in advance, ensure production continuity, and eliminate potential downtime hazards.

Full control of planning system data chain

Scheduling constraints, policy deduction, execution closed-loop tracking

Collaborative group batch, multi-objective optimization, time slicing algorithm, multi-model analysis

Effectively reduce waste, return glue ratio, control material cost

Through the host computer, sensing system, transportation system, cache system, sorting system, storage unit and other processes

Reduce the information uncertainty caused by personnel participation

Complete the traceability system of material flow

Realize the accurate management of edge material

Efficient use and reduction of production space

Establish industry equipment interface standards

Loosely coupled interface management pattern

Efficiently control and monitor equipment running status

Complete the "health portrait" of the equipment.

Improve equipment utilization, ensure production plan and quality stability

Detect the digital twin of the equipment and complete the integration of equipment data and experimental data

It solves difficulties such as multiple report styles and cumbersome management, and opens up business flow and data flow

Data structure, knowledge accumulation, tracking, analysis, speed up research and development efficiency

Help innovation research and development, improve the core competitiveness of products

Realize the people-centered digital workshop management

Improve production site transparency, feedback speed, work efficiency

To achieve a high degree of unity of executive and personnel performance

Make enterprises pay more attention to HSE