Paperless office, improve the efficiency of information transmission

The whole process, standardized quality control, let the quality management become simple

A variety of convenient data collection methods, manual + networking, improve efficiency and accuracy

Quality problem warning upgrade system

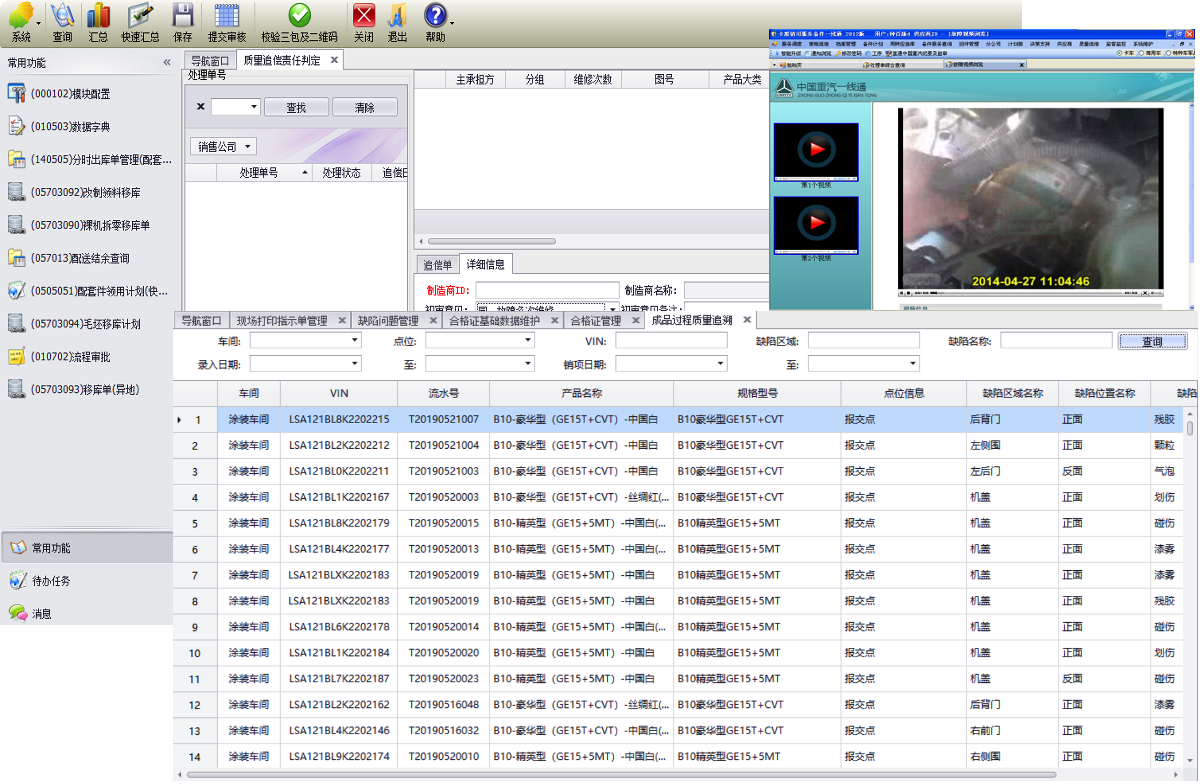

Support and after-sales system quality feedback docking, quality data one-stop analysis, recovery

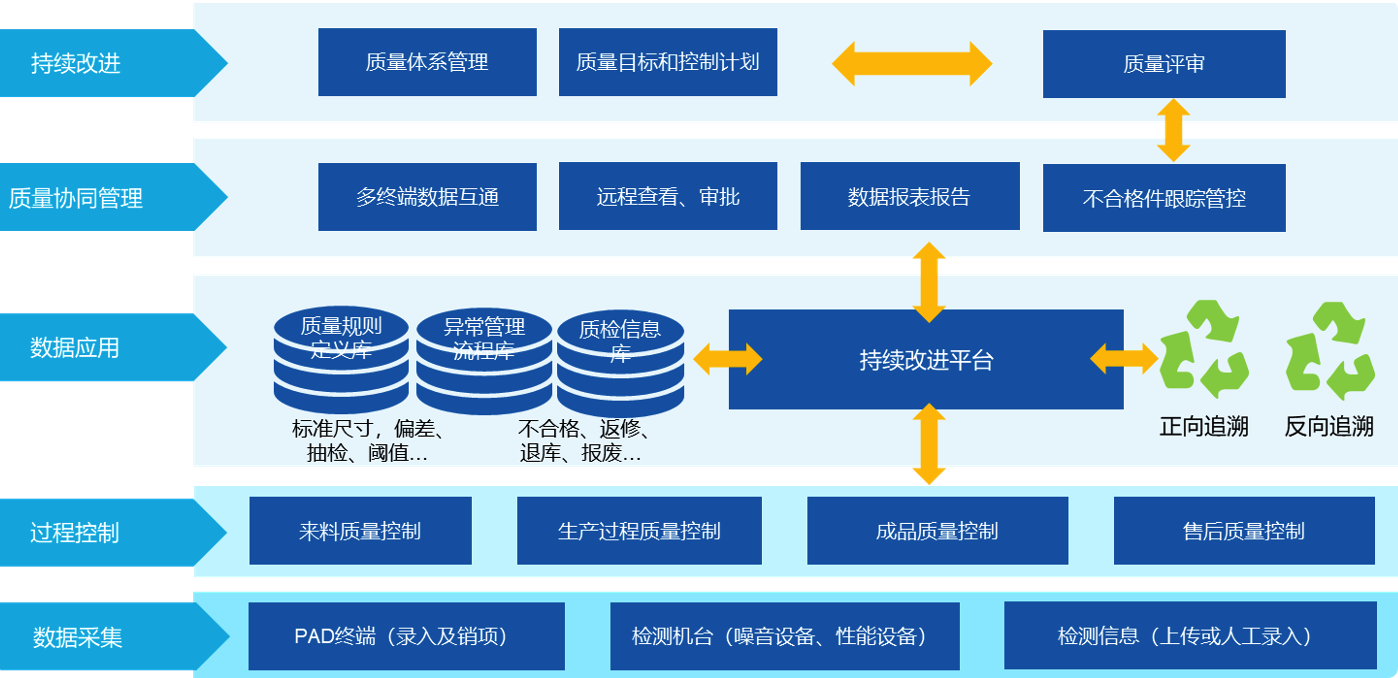

Realize the comprehensive sharing of quality information and complete the forward and reverse quality traceability

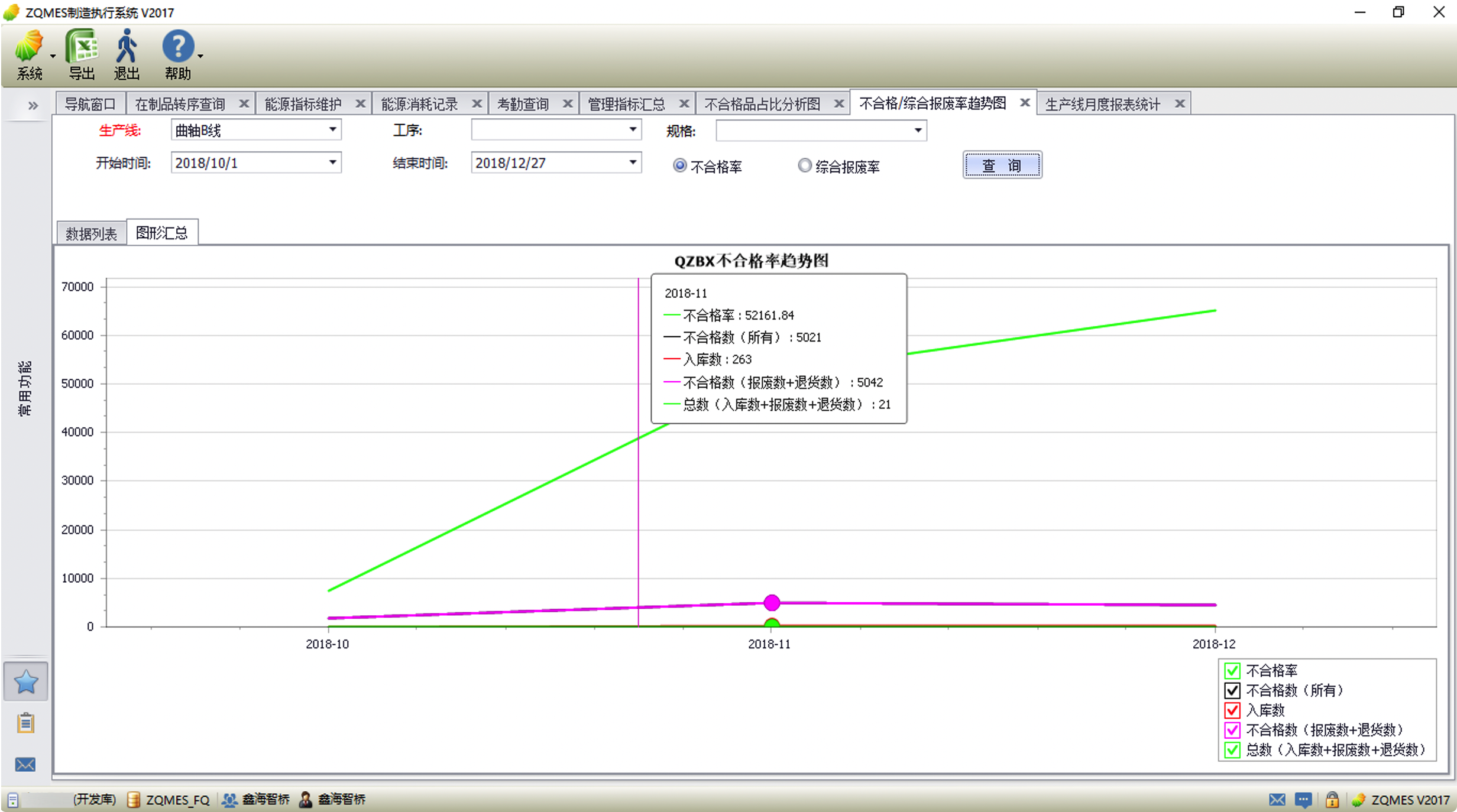

Through SPC, quality control KPI, Plato, CPK and other statistical analysis techniques, improve process prevention and diagnosis capabilities

Scientific adjustment and improvement of machine and process based on real and accurate data

Real-time monitoring quality data, abnormal alarm and related responsible person, improve the efficiency of problem handling

Realize the whole manufacturing process quality management of "incoming material quality inspection - process quality inspection - finished product quality inspection - after-sales quality"

Set up standard quality system and control production process based on quality dimension

Real-time analysis and display of quality KPI, find quality problems and formulate quality solutions