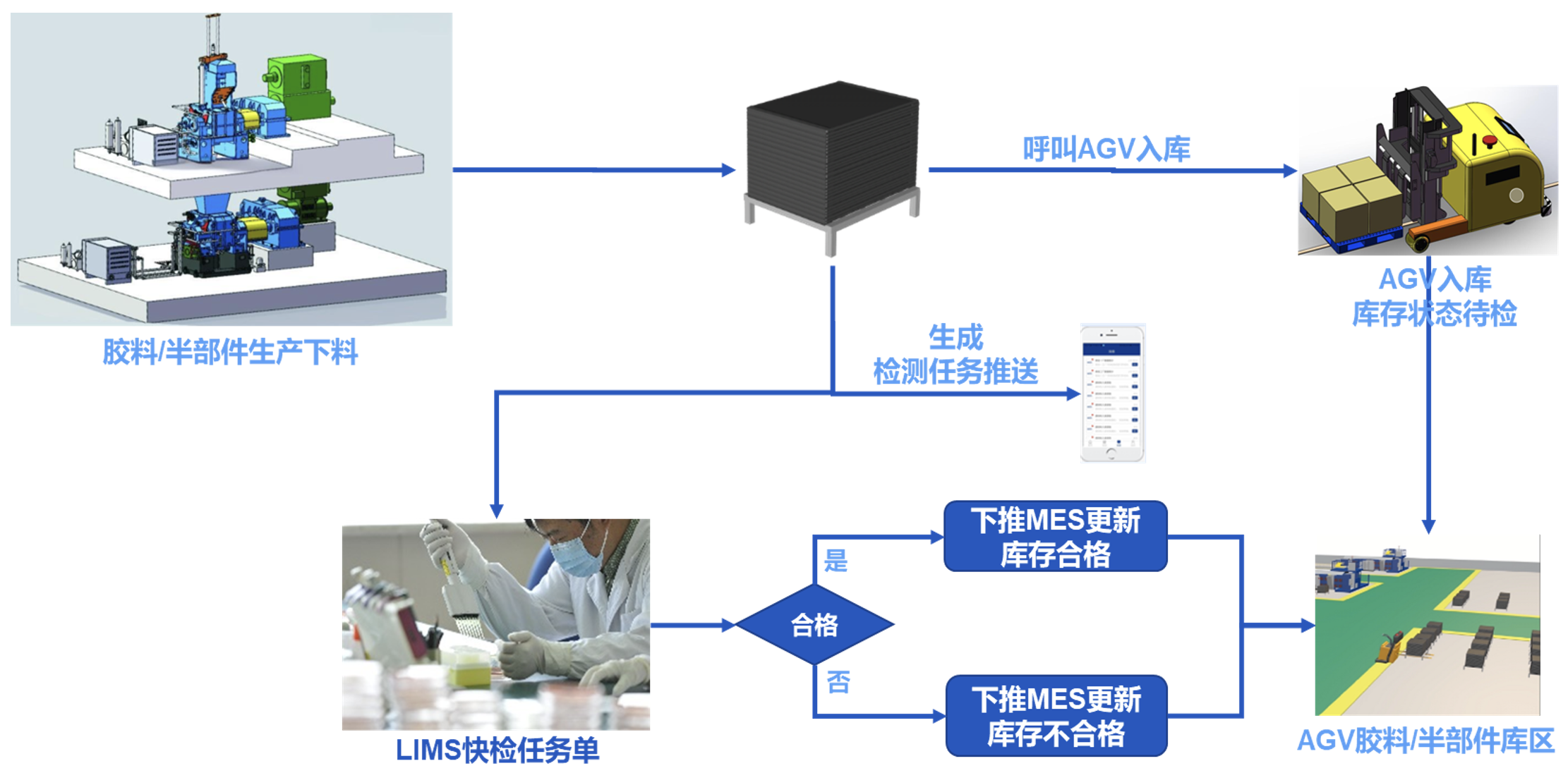

Barcode-based management is implemented at the production site to ensure an efficient and standardized process.

Samples are automatically linked with production materials, enabling seamless data integration and improving management efficiency.

With an intelligent system, the entire sample management process is traceable, ensuring quality, safety, and process transparency.

Test results are automatically determined based on system-defined standards, ensuring accuracy and consistency.

The manual review process supports flexible configuration, catering to personalized needs in different scenarios, achieving efficient management.

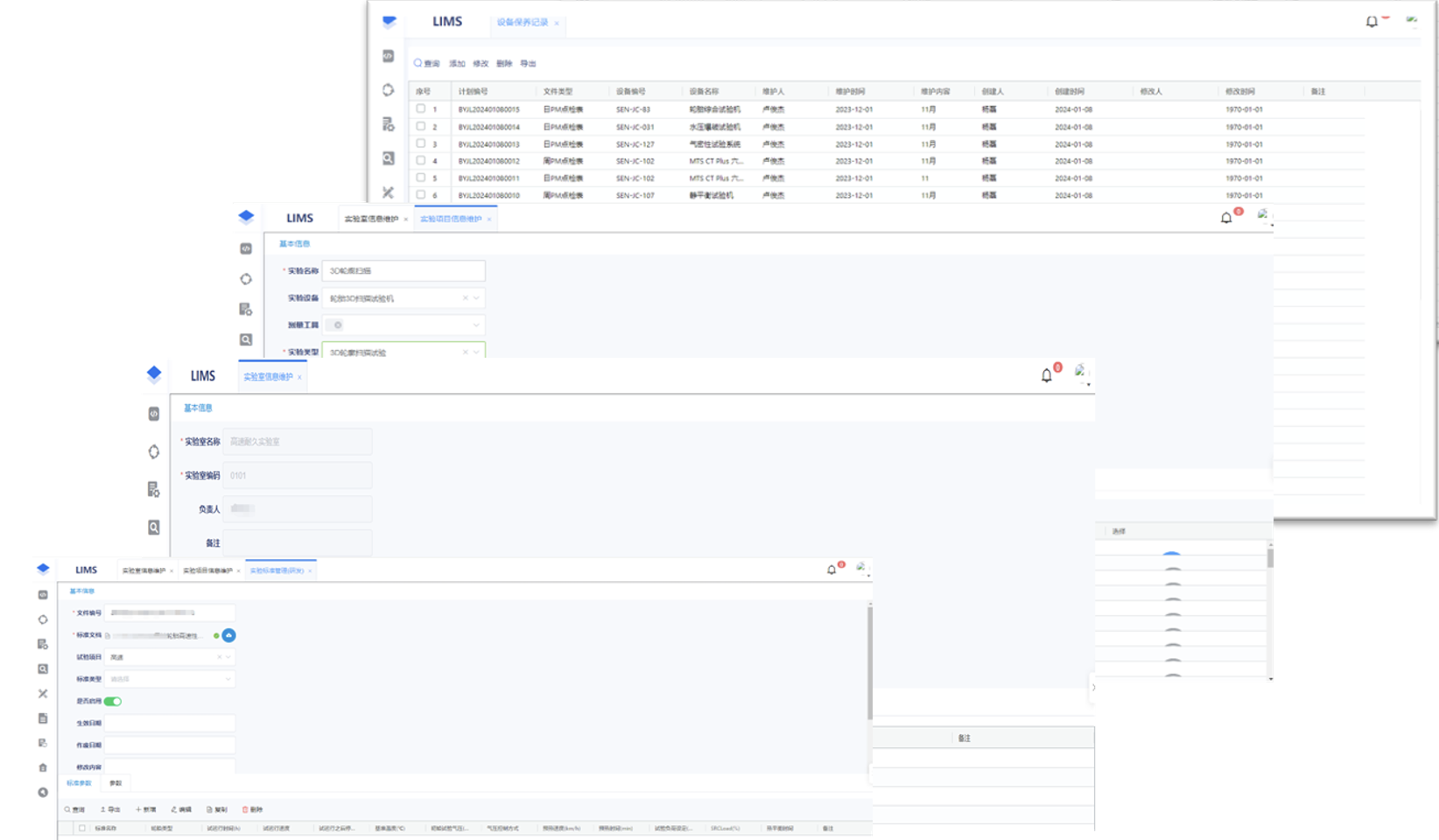

Equipment records and historical data are fully traceable, ensuring transparency and visibility of equipment status.

Measurement and calibration plans are automatically generated with timely notifications, preventing any oversights.

Deep equipment integration allows for automatic acquisition of testing and inspection data, achieving efficient automated management.

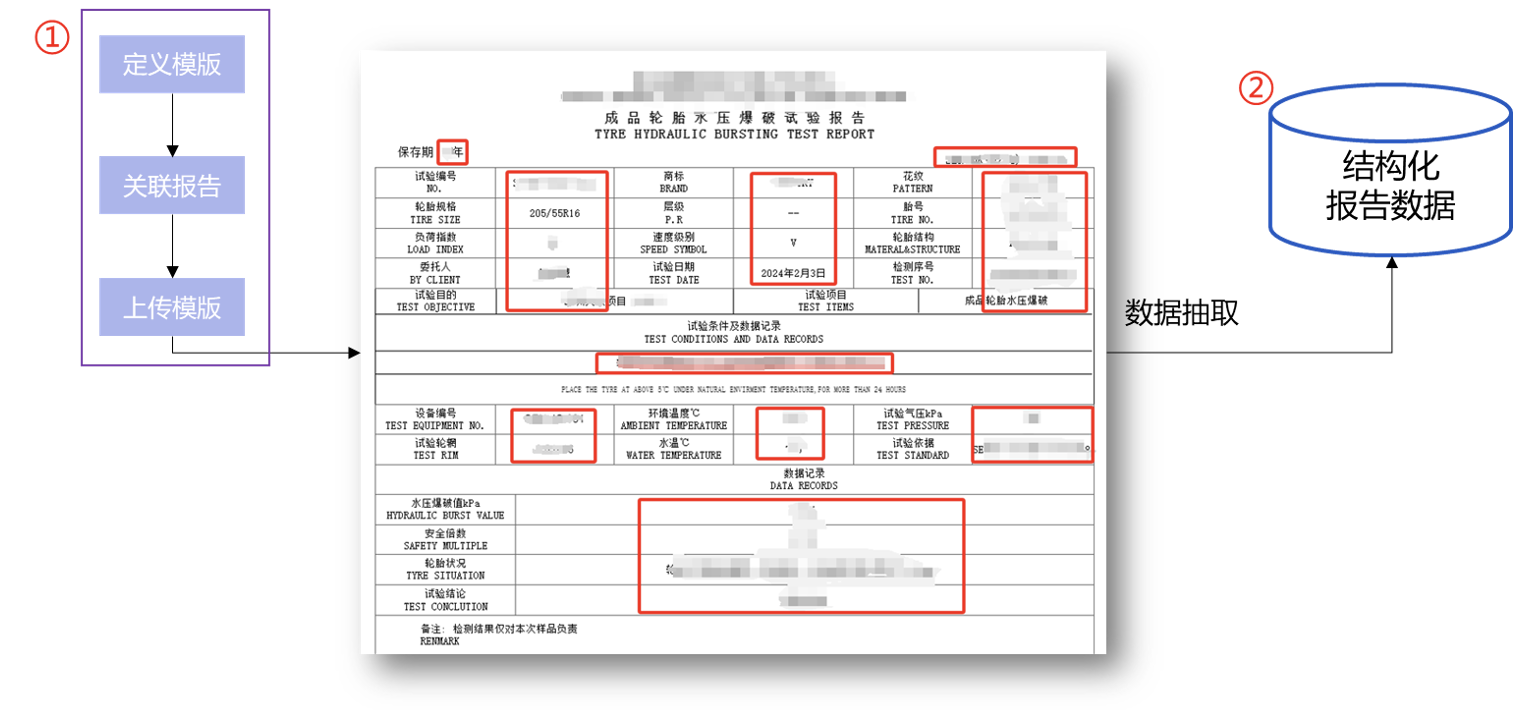

Reports are generated automatically, improving efficiency and accuracy.

Customizable report templates are supported to flexibly meet diverse needs.

Original records and reports are automatically generated, ensuring standardized management and process compliance.

The system fully supports PC, tablet, and large screen displays, meeting the needs of various application scenarios.

Real-time synchronization of information across multiple terminals ensures efficient collaboration between devices, delivering a seamless management experience.