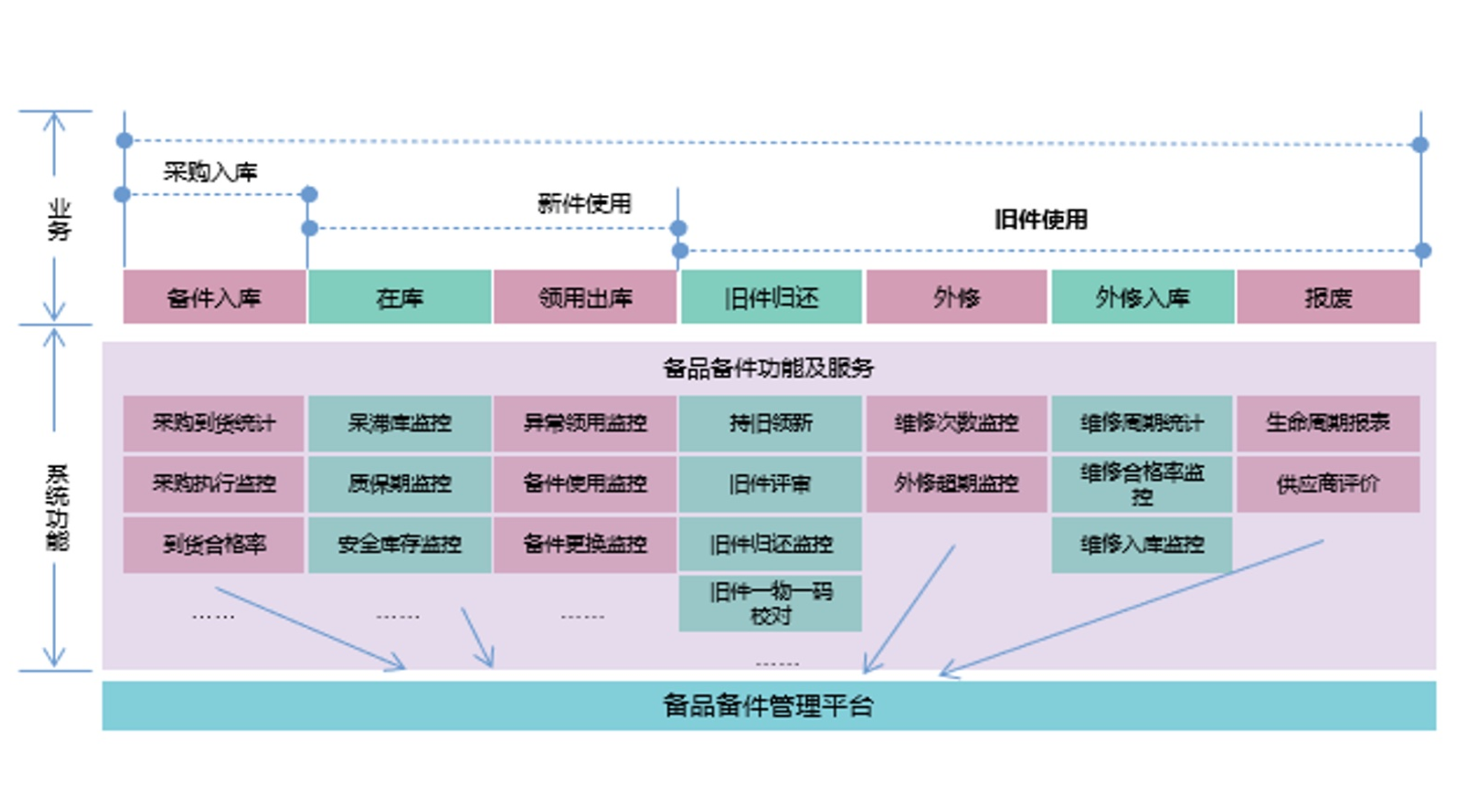

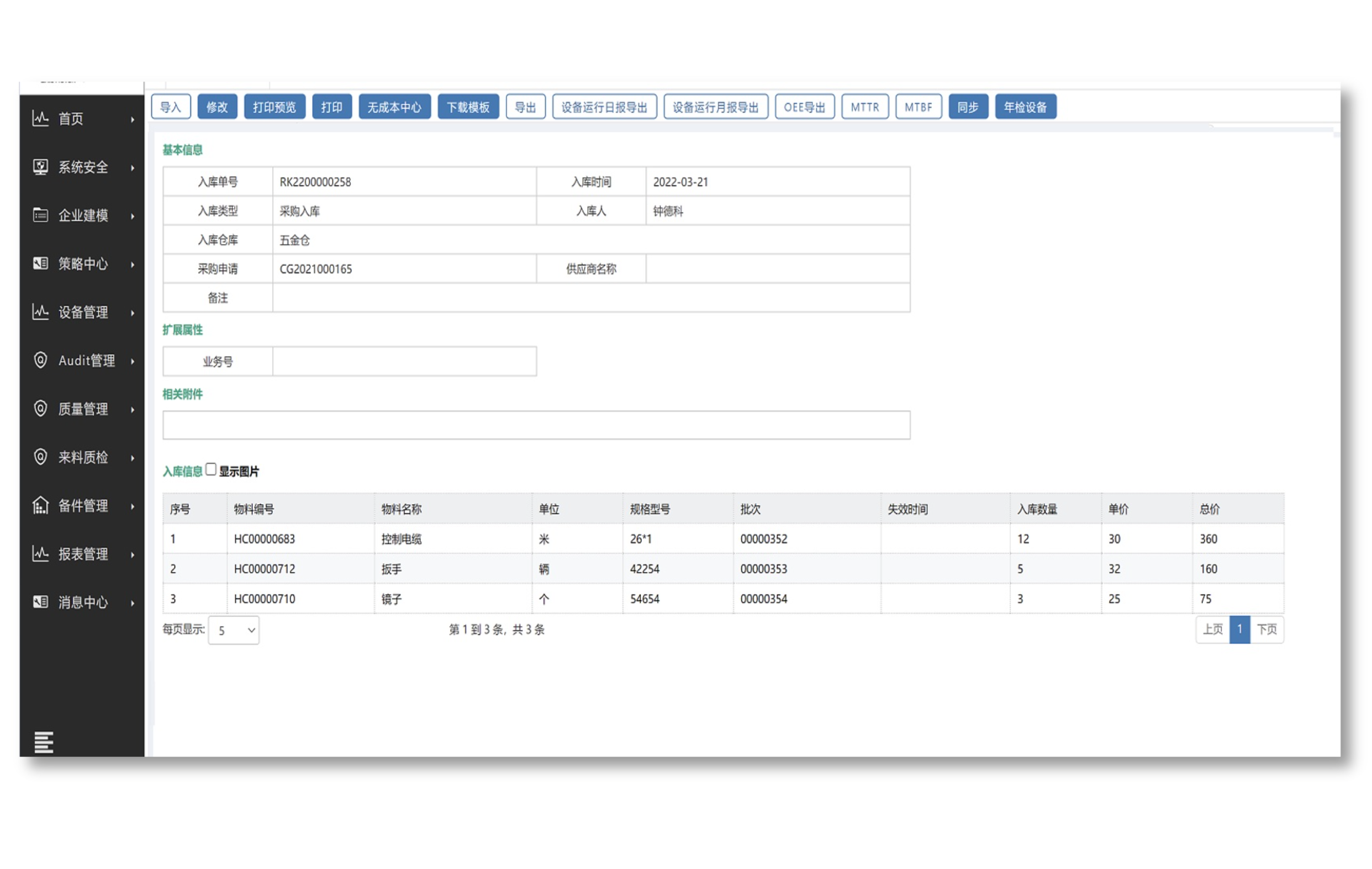

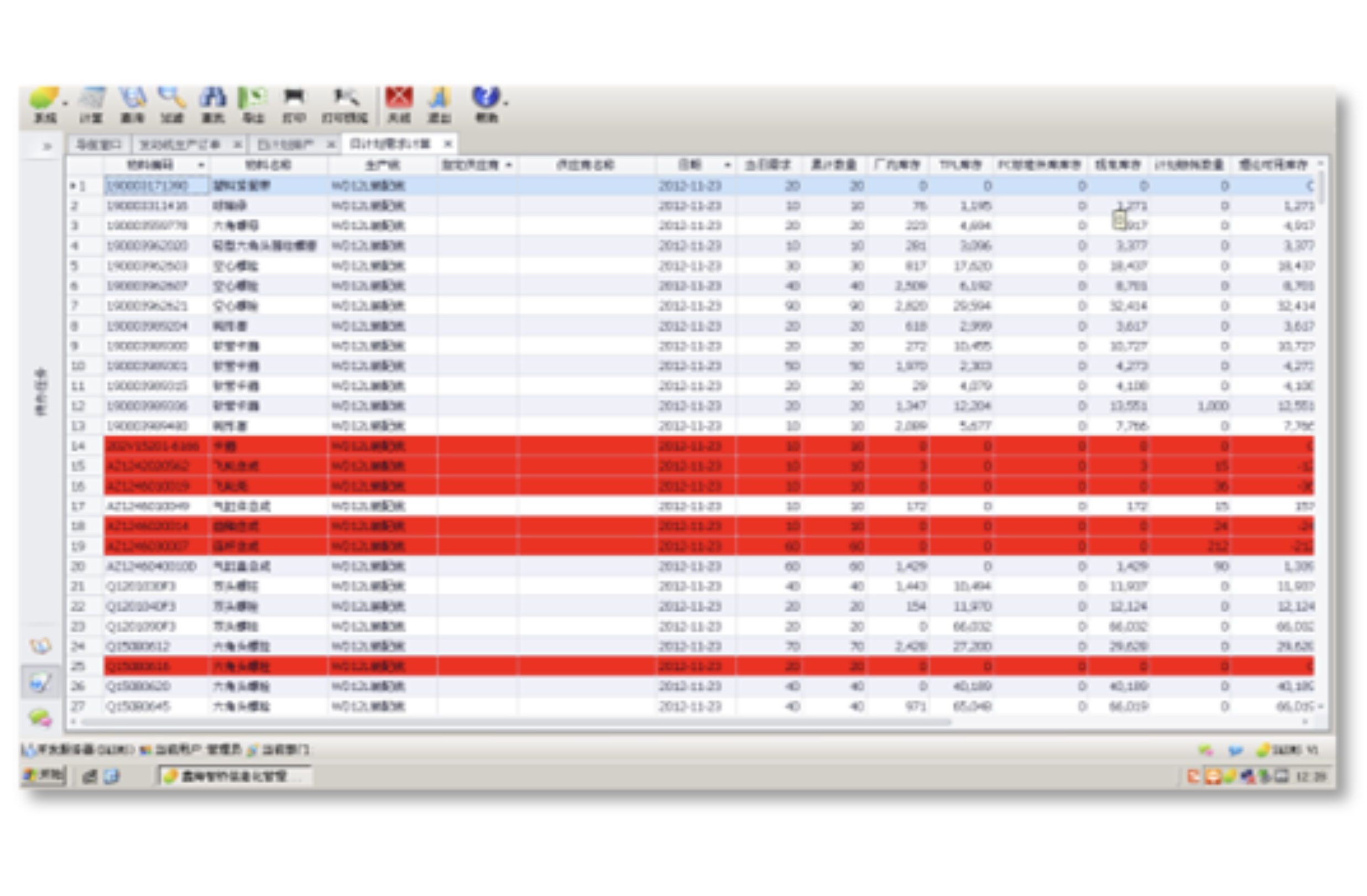

Through information technology, automated management of spare parts storage, outbound, inventory inquiry, inventory counting and loss, warning and reminder functions can be achieved.

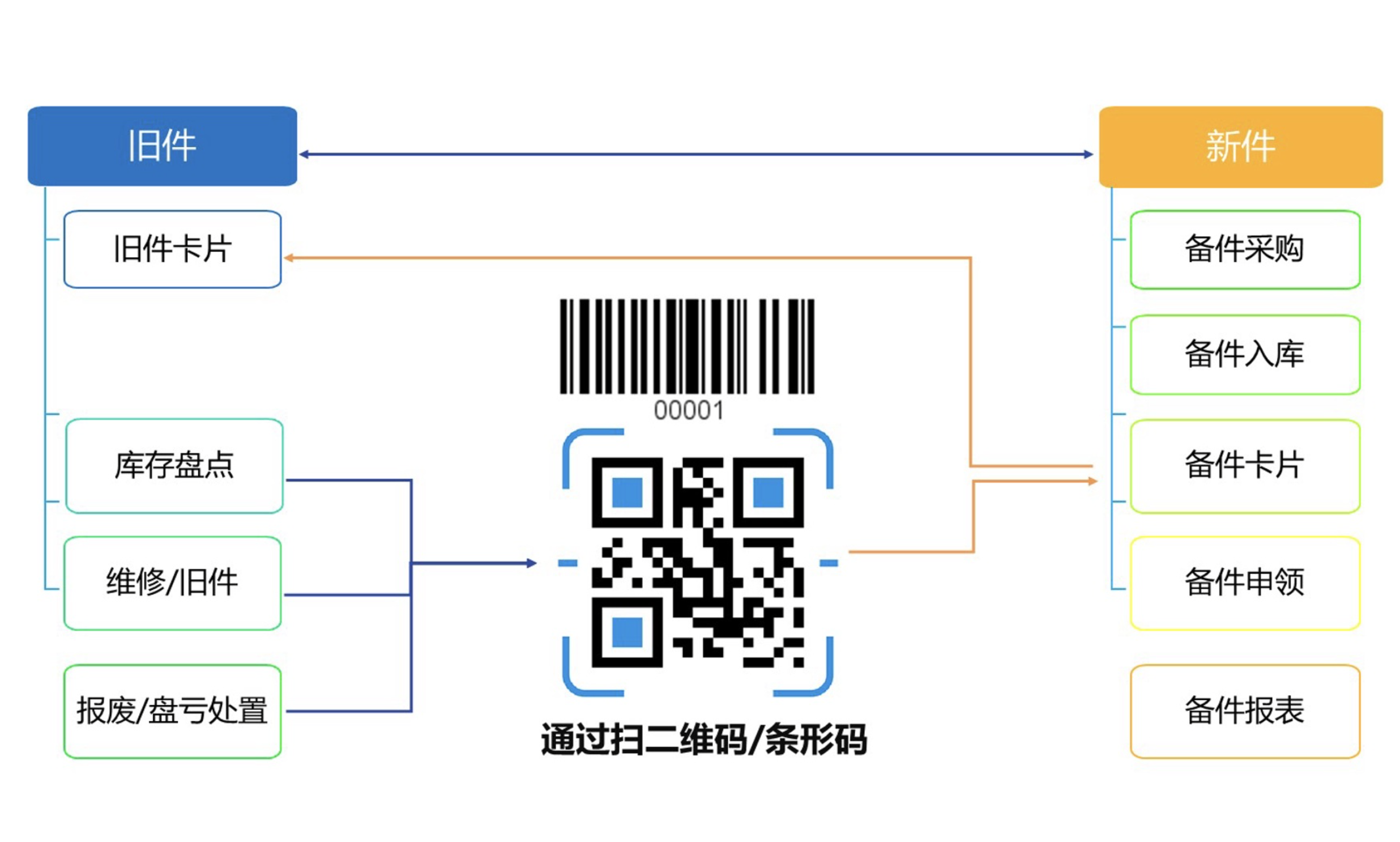

Using QR code technology to achieve fast input and quick query of spare parts information.

For spare parts that require tracking and analysis, configure a one item one code system in SPM.

By using various methods such as handheld terminals and scanning guns for reading, the efficiency of spare parts identification and management can be easily improved.

Real time tracking and management of spare parts, facilitating enterprises to grasp the inventory status of spare parts at any time.

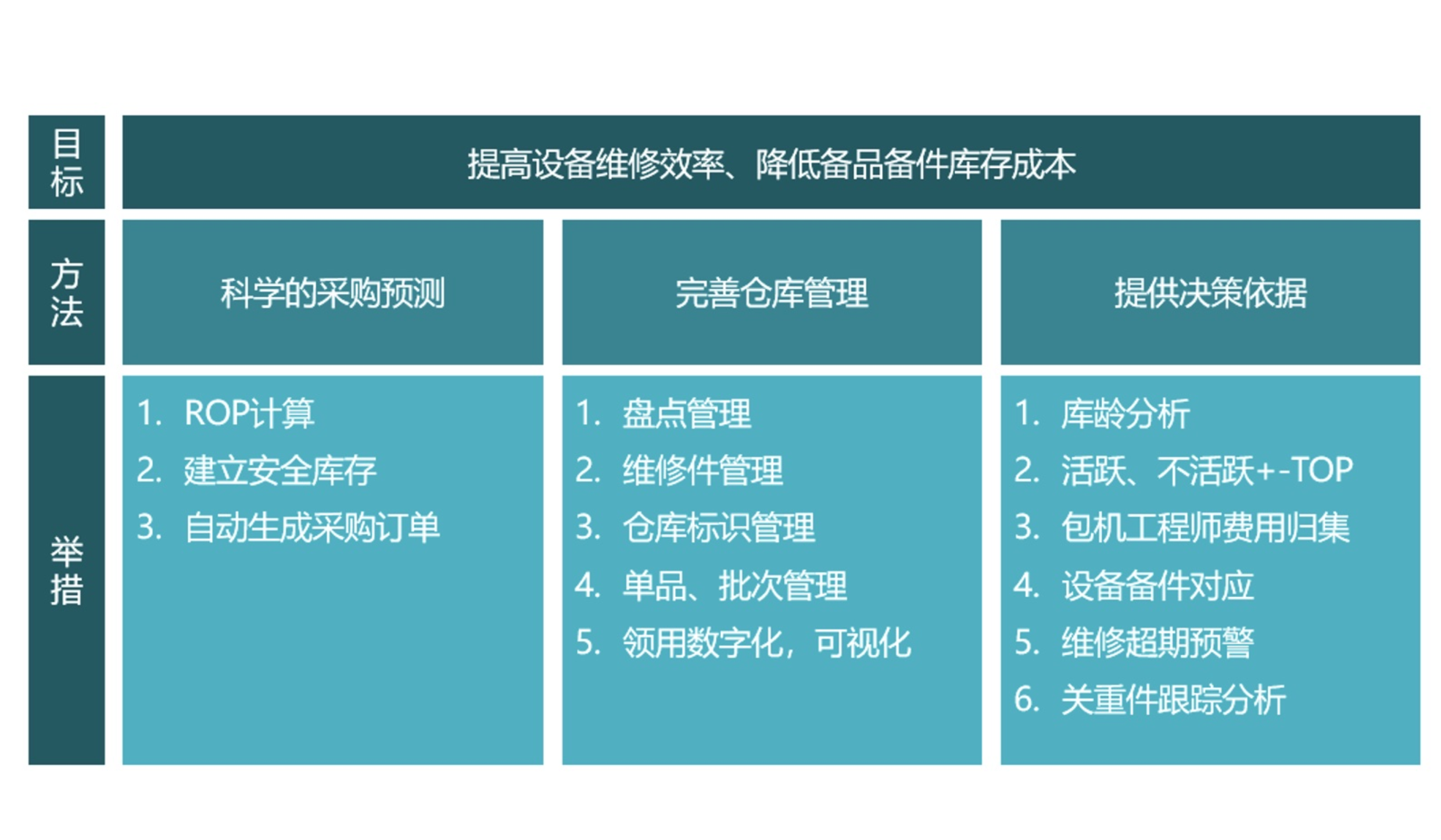

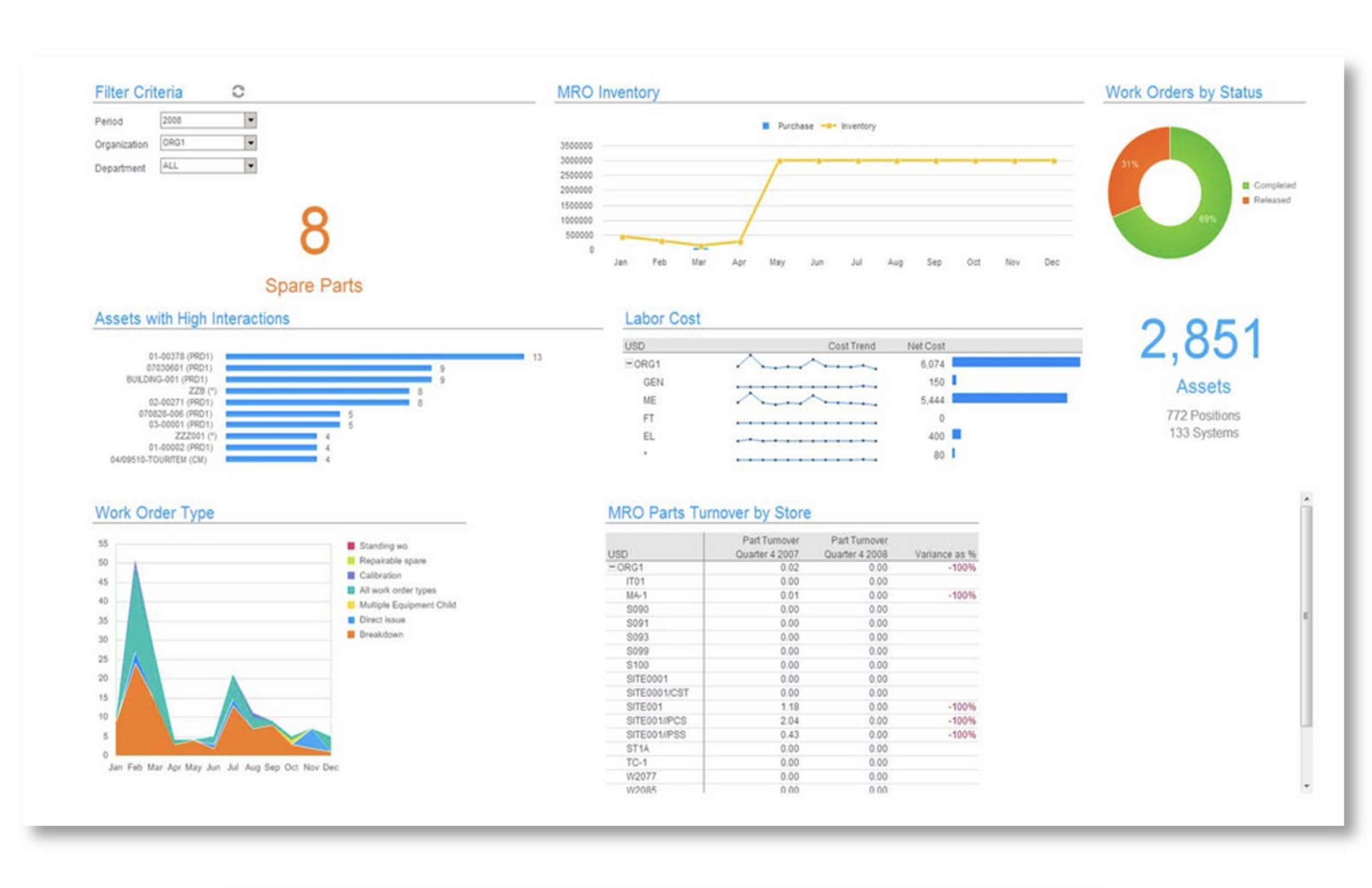

Develop a scientific inventory management strategy to ensure that spare parts inventory is within an appropriate range.

Realize comprehensive tracking and management of spare parts, timely understanding of their usage and inventory status.

Through automated management methods, reduce manual recording and search time, and improve work efficiency.

By tracking and controlling the status of spare parts in a timely manner, it is possible to achieve the protection of equipment's' fine water, long flow ', thereby improving equipment efficiency and enhancing equipment stability.

Reasonable spare parts management can reduce the idle and waste of spare parts, and lower the inventory cost of spare parts.

All operations and data are recorded in real-time and cannot be tampered with, ensuring data authenticity and real-time analysis of enterprise cost control.

Ensure the accuracy and consistency of spare parts data, and reduce human errors.

Support multiple data analysis methods, provide statistical analysis of spare parts inventory, inventory status, spare parts history, spare parts attendance rate, etc.